Question Driveshaft bearing

Driveshaft bearing

QUESTION: Howard,

Just when I thought I was done with this issue, I'm having a problem putting the driveshaft assembly back together. I put in a new crush sleeve and the new inside bearing over the shaft and tapped it down with a pipe, then put a new lockwasher and nut over and tightened them down. The bearing had millimeters of end play but I started having to use the wrench and hammer to tighten the nut ! Is it normal for the crush sleeve to require a lot of force to crush it down ? Maybe I need a bigger vice that won't rotate as easy as it does when I use the hammer. I drove the bearing further by using a pipe and hammer, then resorted to my 12 ton press to get it to about 1 millimeter of end play and the hub still free spinning. The old crush sleeve is .370 wide and the new ones are .438 wide un crushed. Is all this normal ?

Thanks,

Steve.

ANSWER: If the bearing is tight on the shaft it is difficult to tighten the nut as you are trying to overcome the tight bearing and the crush sleeve. Sometimes when you remove an old bearing it scares the shaft a little and that makes the new bearing very tight on the shaft. Also, some bearings are tighter then others.

You must not have any end play when finished with the correct pre-load as we talked about before.

The old crush sleeve is already crushed so it will be shorter then the new one. Sometimes it helps to use a little heat on the inner race to get it to slide on the shaft but you must be careful with heat as you can destroy the hardening of the race if you use too much heat and the bearing will soon self destruct in a short time.

Howard

---------- FOLLOW-UP ----------

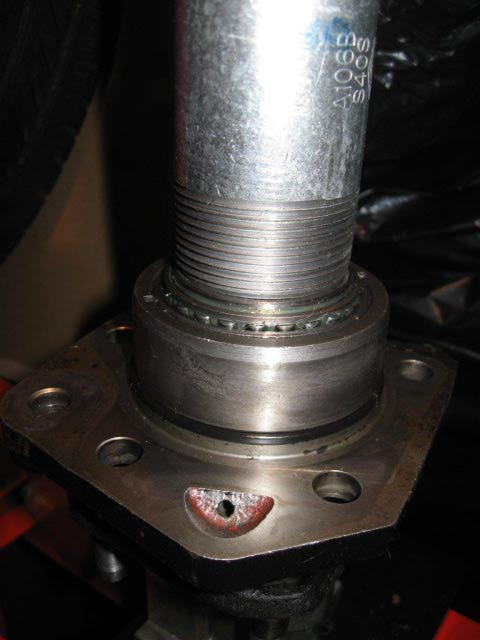

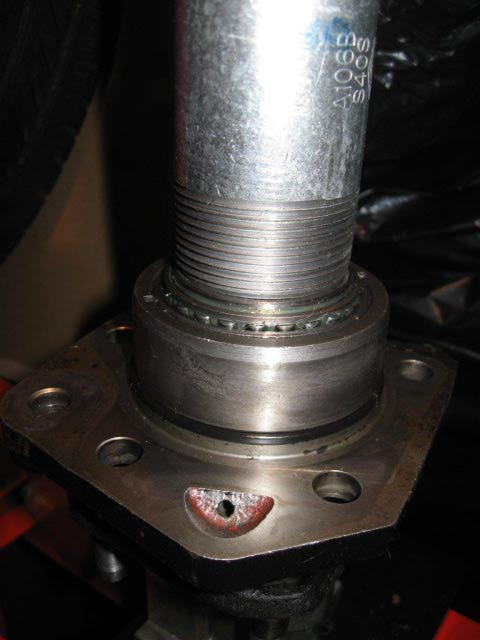

driveshaft bearing

driveshaft bearing  driveshaft bearing2

driveshaft bearing2

QUESTION: Howard,

I was able to tighten up the nut - I took the swivel base off my vice and bolted the vice directly to my bench so it wouldn't shift every time I cranked on the wrench. I have it now at 4 inch pounds to just turn it, my arm is 4 inches from center and the hammerhead weight in the photo is 1 lb. I'll use a 2 lb weight to finish it. I'm surprised the preload is supposed to be 8 inch pounds, I can feel the drag when I turn it by hand now at 4 inch pounds. When I've set up front wheel bearings in the past I've always backed off a flat to give it some slack. Just curious, but is that because they heat up more due to the brakes being closer and therefore need more clearance than these driveshaft bearings?

Thanks,

Steve

AnswerAny time they give a figure of inch lbs, I often wonder because I have noted different resistance just from different brand seals and I even tested different lubes on the seals and got different readings. Some double lip seals are really tight. A seal can upset the actual pre-load on a bearing. But in this case you can set it and add the seal afterward.

The pre-load can be set without the seal when the center spacer is a solid spacer and shims are used to get a specific pre-load but in the case of a crush sleeve is used you can't do that and have to depend on the correct seal to get an accurate load on the bearing.

I have always thought that the specs are just a target to aim at.

Howard