Question

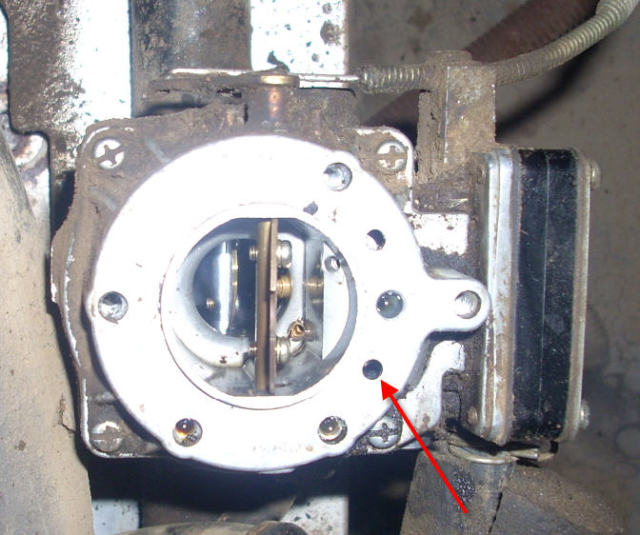

Carb Photo

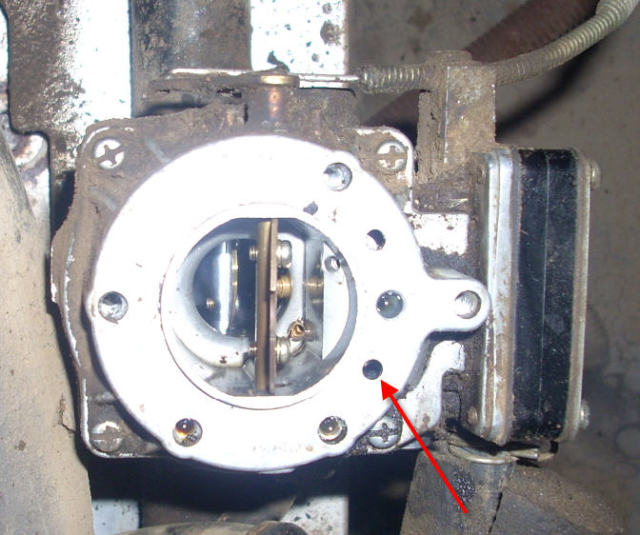

Carb Photo

I have a Murray lawn tractor with a 17HP Twin Briggs and Stratton model 42A707 engine. This afternoon I started it up and shortly after it was sputtering and blowing black smoke, obviously running too rich. I removed the air filter cover and discovered that the air filter was soaked in gasoline. I removed the filter and started it up and was surprised to see gas spraying back up the throat of the carb and fuel leaking into the air filter holder. I looked down the throat of the carb and could see the shimmering of fuel at the bottom, leading to the intake manifolds.

I disassembled further and discovered that shortly after starting up, but not immediately, gas is pouring out of the hole indicated by the red arrow in the picture. I took the cover off the fuel pump suspecting something wrong there but the membrane seemed fine.

Any ideas on what is happening here?

Many Thanks

David

AnswerHello David:

Check the Carburetor Needle Valve and Seat (Small Flat Sided O-Ring). The Hole you are Indicating is the Carburetor Bowl Vent. If Gas is Entering through this Hole, then the Carburetor Needle Valve is Not Seating Properly and Allowing the Engine to Flood. A Small Piece of Trash May have Lodged between the Needle Valve and the Needle Valve Seat. You can View a Breakdown/IPL of this Engine at this Site Addy, http://www.outdoordistributors.com/ and Select the B. Then Select Briggs and Stratton. Then Select Don't have Part Numbers. Then Select the File # 42. Then Select the Folder # 42A700. The Carburetor is Shown on Page 7. I Suggest you Use Carburetor Cleaner (in Spray Can) and Try the Engine Again. If you Still have the Problem, then I Suggest you Soak and Clean the Carburetor and be Sure to Replace the Needle Valve and Seat. The Following is a General Instruction File for Carburetor Cleaning. Even though the Carburetor Looks Clean, the Internal Passages May be Restricted with Varnish that Gas Causes to Build Up over Time. I Suggest you Make Sure the Gas is Free Flowing to the Carburetor Inlet Port. If the Gas is Free Flowing to the Inlet Port, then **Remove, Disassemble and Soak the Carburetor Overnight in Carburetor Cleaner (I Use Gunk). I have Found that Most People can Use a Breakdown/IPL and Disassemble the Carburetor Enough for Proper Cleaning. You Only have to Remove the Bowl (if Applicable), Float Pin (if Applicable), Float (if Applicable) and Needle Valve and Any Adjustment Screws that Go Into the Carburetor Body. The Welch Plugs Do Not have to be Removed. Then Soak the Carburetor Body and Parts in a 1 Gallon Can of Gunk Carburetor Cleaner Overnight. The Can has a Parts Tray Inside it for the Small Parts. Once the Carburetor and Parts are in the Cleaner, you can Replace the Lid for Safety and to Prevent Accidental Spillage. Then Blow Out the Passages with Compressed Air.*** (Do Not Use High Pressure Air for the Zama Carburetors (Zama Carbs that are Used on Trimmers), they have Check Valves for the Primer and these are Usually Blown Out of the Carburetor if Not Careful. Allow the Zama Carburetor to Set on a Drip Pan and Dry)***. Install New Parts if Required.** If you Hit a Snag or this Does Not Correct the Problem, I am Here if You Require More Assistance. Hope this Helps. Let me Know What Happens, Please. May the All Mighty Bless You and Yours. Thanks.

Good Luck

Respectfully

John

PS: I am Allowed to Answer 10 Questions a Day. If you See I am Maxxed Out, then Try Submitting your Question at or Just After 8pm EST (US). My New Day Starts then. Thanks.

Respectfully

John