Triumph Repair: TR7 valve adjustment

Question

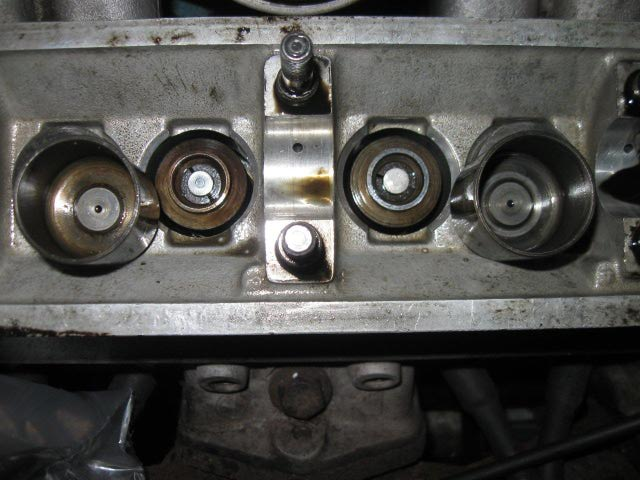

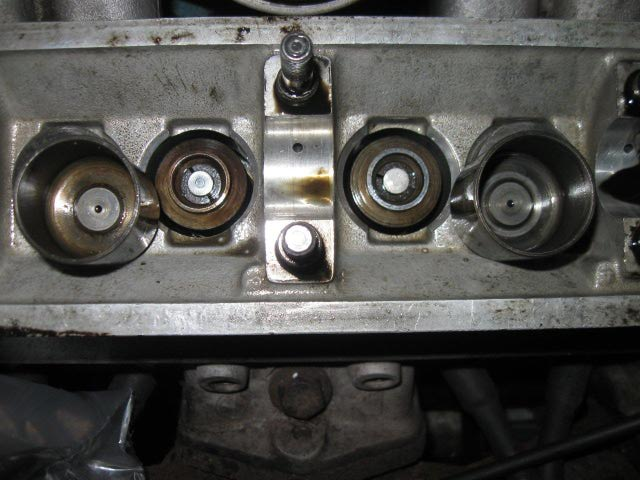

Wear on right valve

Wear on right valve

Hi Howard,

After working on the valves on my E-Type I decided to check them on my TR7 and found them all to be tight. One exhaust valve is particulary bad - clearance is .007 when it should be .018. The shim underneath was the thinnest of them all at 87 thou, but then I noticed the valve collar at the top is making contact with the underside of the bucket. See photo - right valve. You can see the shiny ring on the collar and inside the bucket. So the shim isn't in contact, it sits well below the collar. The edge of the ring on the collar is actually sharp from the wear. I suppose that valve is badly burned or the seat is worn down. I don't think a thinner shim is going help. I suppose a valve job is in order ? I can't say I'm too keen to do that especially since I've heard the head can be a bear to remove ! Any other suggestions ?

Thanks again,

Steve

AnswerHi Steve,

I have seen that before. You need to check to see that the valve and keepers are in good shape and check installed spring height on that valve. Also check for any valve seat recession. Sometimes when a head warps the machine shop shaves the head to get it flat again. (the heads always bow up in the middle) then when the head is resurfaced that makes the #2 and #3 cylinder cam bore also bowed.

If the machine shop has the samll boring bar they recut the cam bearing surface which makes all the valves on #2 and #3 cylinders short. The shims that Triumph supplies are not thin enough to get the valve clearance correct but many Triumph mechanics know The SAAB 99 uses the same shims but has them in a lot thinner sizes so they use them. But when they put in shims too thin the lifter hits the collar. The correction when this happens is to either grind down the lip on the collar or use a lathe to cut into the inside of the lifter. Some mechanics grind the ends of the valve stems to try to get the clearances correct thus the collar hits the lifter.

But the sequence must be to look at the stem and keepers first, then measure the installed spring height, then make corrections to the collar or lifter and use SAAB 99 adjustment shims.

I have saved many over heated and bowed heads this way myself and for local shops and machine shops. Check the head surface for flatness and then install the cam with no valves to see that the cam bore is straight and the cam spins free. This trips up many normally good mechanics and even auto machine shops. They often have engine failures after a fresh rebuild because of this strange designed engine. (The V-8 Triumph Stag and the SAAB 99 too)

Howard