The cars and trucks we drive are often the bad guys in Earth Day stories, lambasted for the pollutants they emit and the resources they gobble. But for much of the past decade, automakers have been developing ways to make their vehicles environmental heroes.

What could be more earth-friendly than using ground-up volcanic rock instead of man-made chemicals to fashion soft-to-the-touch, easy-to-clean roof support pillar coverings for a sedan?

Hyundai does that. And it's far from alone when it comes to the greening of the automobile.

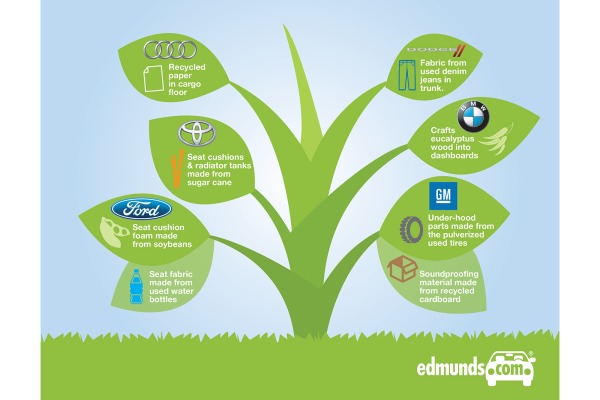

Soybeans, Sugar Cane and Old Tires

Ever hear of a seat cushion foam made from soybeans instead of petroleum-based chemicals?

Ford Motor Co. researchers invented the foam in a biomaterials lab in Dearborn back in 2007. It debuted in the 2008 Mustang and now is used in every seat cushion in every Ford and Lincoln model sold in the U.S. Ford also has made the material available to other automakers.

How about air baffles and other under-hood parts made from the pulverized remains of tires that have been worn out on automotive test tracks? That's a General Motors recycling project, as is soundproofing material made from recycled cardboard packaging from parts suppliers.

Toyota makes seat cushion material, radiator tanks and other components from bioplastics that use glycol from renewable sugar cane instead of petroleum-derived glycol. BMW crafts sustainably grown eucalyptus wood into dashboards for its i3 electric car. Recycled steel? Much of the steel in cars and trucks today is recycled. So is a lot of the aluminum.

Seeing Green Everywhere

The use of sustainable materials has become so widespread, in fact, that several automakers had difficultly answering when asked to provide examples of a few models that stood out for their renewable or recycled parts.

Volvo, for instance, said that almost all of its vehicles use some recycled content. The company's focus "drives us to reduce our environmental footprint...including [use of] recycled materials and remanufactured parts across our products," according to Volvo sustainability spokesman Niklas Kilberg.

That widespread use isn't limited to Volvo. Indeed, automakers use recycled steel, aluminum and plastics in almost every car on the road today.

Renewables and Reuse Boost Revenue

It turns out that for most automakers, being green means not only improving fuel efficiency in vehicles and using renewable energy from solar, wind and hydro power in their offices and factories.

They also work to eliminate waste by recycling everything from the cardboard centers of toilet paper rolls to the metal shavings from their assembly plant floors.

Subaru has long prided itself on being a zero-landfill company, and most other major automakers are striving for the same goal. General Motors Corp. says it now was 122 plants around the world that are "landfill free."

John Bradburn, GM's waste reduction manager, says the company boosts its revenue by more than $1 billion a year through recycling and reuse. Ford says that it saves more than $10 million a year in North America alone by using recycled materials in its vehicles.

Ford is also a leader in the development and use of plant-based plastics to replace petroleum-based products. It maintains a team of special biomaterials researchers whose products now go far beyond those soy-based foam car seats. A recent development of Ford's biomaterials lab is a composite plastic that's reinforced with rice hulls and was used for the first time in the wiring harness of the 2014 Ford F-150 pickup.

From Cartons to Cars

Often, the recycled material that comes from a carmaker's factories goes back into the same company's vehicles.

GM, for example, worked with a number of parts suppliers to have cardboard shipping containers made from a proprietary blend of wood pulp fibers. When those containers are emptied of their parts on GM's factory floors, the cardboard goes out for recycling and comes back as sound-deadening material that's used in the headliners of the Buick LaCrosse and Verano models.

Ford, GM and others use the tires that their test-drivers wear out at their proving grounds to obtain rubber for various under-hood and under-body parts — mainly flexible pieces, such as airflow baffles and diverters.

Green-Car Roll Call

It's getting easier to find vehicles that can make every day Earth Day. Here's a sampling of vehicles on the market today that use sustainable and recycled materials:

Audi

A3: Cotton fiber in floor insulation, recycled paper in cargo area floor, cellulose in headliner.

BMW

i3: Plant-fiber-reinforced material in door cladding, recycled plastic fabric seat covers, renewable eucalyptus wood dashboard.

Buick

LaCrosse and Verano: Sound-dampening material made from recycled cardboard.

Cadillac

ATS, CTS and ELR: Under-hood air and water baffles made from recycled tires.

Chevrolet

Silverado: Radiator shroud made from recycled plastics, air and water baffles made from recycled tires.

Colorado: Air and water baffles made from recycled tires.

Volt: Recycled cloth used for sound-deadening material throughout.

Chrysler

300: Recycled plastic in console and center stack.

Dodge

Charger: Recycled plastic in console and center stack.

Dart: Fabric from recycled denim jeans in trunk liner.

Ford

Edge: Fiber from recycled plastic water bottles in all seat fabric.

Escape: Soy-based foam in headliner, castor-oil foam in instrument panel, bioplastic in door panels, nylon resin from recycled carpets in cylinder-head covers.

Flex: Seals and gaskets made with soy oils and recycled tires; wheat-straw reinforced plastic in storage bins.

Focus: "Water bottle" seat fabric, soy-and-tire seals and gaskets

Fusion: "Water bottle" seat fabric, soy-and-tire seals and gaskets, recycled carpet resin in cylinder-head covers.

F-150: Rice-hull-reinforced composite plastic in engine wiring harness, "water bottle" seat fabric, recycled carpet resin in cylinder-head covers.

Mustang: "Water bottle" seat fabric, recycled carpet resin in cylinder-head covers.

GMC

Sierra: Radiator shroud made from recycled plastics; air and water baffles from recycled tires.

Honda

Accord Hybrid and Accord Plug-In Hybrid: Proprietary Bio-Fabric in seat covers.

Hyundai

Accent: Volcanic rock-based plastic composite in roof support pillars.

Elantra: Soy-based foam seat cushions.

Jeep

Cherokee: Soy-based body sealant.

Wrangler: Recycled plastic in underbody shields and wheelwell liners.

Kia

Rio: Soy-based seat foam.

Soul EV: Cane- and cellulose-based bioplastics in door panels, headliner, seat fabric, roof pillars and carpeting.

Lincoln

MKX: Reinforced plastic using cellulose from sustainably grown trees replaces fiberglass in center console.

Lexus

CT 200h: Bioplastics in carpeting and luggage compartment liner.

RX 450h: Bioplastics in seat cushions.

Mercedes-Benz

C-Class: Recycled plastics in 52 components including wheelwell liners, bumpers, air and water baffles; material from renewable natural fibers used in 76 components including interior trim pieces.

GLA-Class: Recycled plastic in 41 components including wheelwell linings, recycled paper in luggage compartment cover.

Nissan

Leaf: Recycled soft drink and water bottles used in seat cover fabric; recycled jeans and other cloth used for sound-deadening panels; recycled automotive and household plastics used in most plastic components.

Toyota

Camry: Bioplastics in radiator tank.

Corolla: Bioplastics in seat cushions.

Prius: Bioplastics in seat cushions, some trim pieces and air vent registers.

RAV4: Bioplastics in seat cushions.

Volkswagen

Golf: Cotton fiber in floor insulation, recycled paper in cargo are floor, hemp and flax fiber in door panel trim.