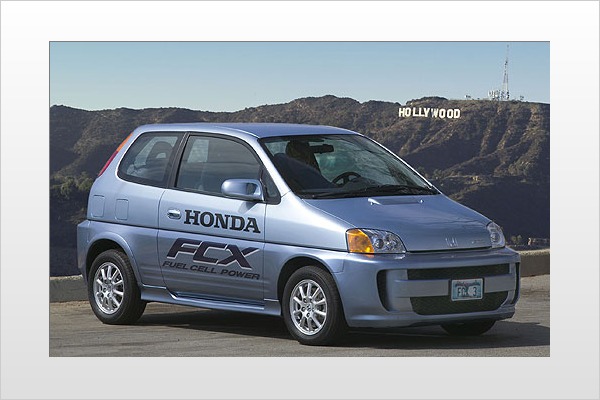

When I exited the hotel with Steve to drive the Honda FCX, I headed straight for the vehicle that was on display with the other fuel cell cars just outside the entrance of the Renaissance Hotel in Hollywood.

"Wait a second," Steve called to me and I turned to see him fishing the valet claim check out of his pocket. He handed it to the parking attendant, who retrieved the key from the board and wandered off.

"You valet parked it?" I asked incredulously, finding it amazing that Steve Ellis, manager of sales and marketing for American Honda's alternative fuel vehicles, handed over the keys of a multimillion-dollar, hand-built, prototype car to a hotel parking attendant.

"Why not? It wasn't like there was much choice," he said. It was true. Hotels in the city are famous for making self-parking difficult.

But what was even more startling than handing over the keys of a multimillion-dollar car was that there were no instructions that came along with operating it. I was amazed, considering that the Honda FCX does not run on gasoline (it runs on pressurized hydrogen) and it is powered not by an internal combustion engine, but by a fuel cell and an electric motor.

As if to demonstrate my point, the attendant pulled the FCX up a moment later and held open the driver door for me. I looked at him carefully, trying to discern if he had any clue what he was driving. His brown eyes met my gaze warmly and he smiled and said, "It's running, ma'am." Good thing he mentioned that, because this car doesn't make any noise, except for the occasional fan turning off and on.

The hotel where Steve had valet parked the car was the site of the 15th Annual U.S. Hydrogen Conference, and I was there to learn everything I could about the future of the automobile. That included meeting Steve for a drive through the Hollywood Hills, where I would have the opportunity to put the Honda FCX through its paces. Since I was familiar with the area, I planned a route that was a combination of highway, city streets and canyon roads — about 40 miles in all.

In a nutshell, the experience was remarkably unremarkable. In fact, it was similar to driving any one of a multitude of gasoline-powered, internal combustion-engined cars on the market today. This was true not just for the Honda FCX, but for my driving experiences in the Toyota FCHV and General Motors' HydroGen3, two other fuel cell vehicles.

"We've worked hard to make the FCX's driving experience like driving a Honda with an internal combustion engine," Ellis said. Indeed, the car performed almost exactly the way a gasoline-powered vehicle would, even down to the "creep," which allowed the car to roll forward slowly when I took my foot off the brake, a feature that is inherent in the design of a vehicle with an internal combustion engine, but one that had to be engineered into the FCX.

On the Road in a Fuel Cell Vehicle

From the exterior, there is nothing about each of these vehicles, save for badging and paint schemes, that makes any of the fuel cell vehicles I drove stand out. On the inside, each vehicle was nicely finished and did not look at all the part of a vehicle of which there is only a handful in existence.

Even the driving experience was shockingly similar to driving today's gasoline internal combustion cars with two notable exceptions — these vehicles have no engine noise (which takes a bit getting used to) and, my favorite quality, all had a surprising amount of low-end torque, making them quite fun to drive. So much so, that when I got in my daily driver, a Saab 9-5 Aero wagon, it felt downright wimpy.

That impressive low-end torque is pretty amazing for vehicles that generally weigh more than today's gasoline-powered cars. The Toyota FCHV, which is based on the Highlander, was noticeably faster than its gasoline-powered counterpart. Craig Scott, a senior strategist in Toyota's advanced technology group says that the FCHV is about a half-second faster to reach 60 mph than a four-cylinder Highlander, even though the fuel cell vehicle weighs 570 pounds more.

The three fuel cell vehicles I drove were so well constructed, performed so nicely and were so, well, normal-looking, that it was hard to believe I couldn't stop by my local dealer to buy any one of these vehicles right now. Appearances, however, can be deceiving. In this case, the auto industry as a whole agrees that there is much work to get fuel cell vehicles to the point where we can find them on the showroom floor. And to be sure, getting them on the showroom floor is the eventual goal, although exactly how long that will take is anybody's guess. Estimates range from five to 15 years.

Virtually every automaker, as well as a host of suppliers, energy companies and educational institutions, is conducting R&D on fuel cell vehicles. Many are using federal monies allocated for this purpose in combination with plenty of each companies' own private funds. Yet getting fuel cell vehicles to the point of mass production is no easy task. The issues the industry faces are both complex and intertwined in terms of technology, fuel infrastructure, safety and cost.

"It is my dream to see this happen for society, but we all have a long road ahead to get there," said Bill Reinert, national manager for advanced technology groups at Toyota. "The cost is still very high, storage and distribution are big issues, and we still have a lot of research to do on the technology."

It's About Oil

Getting alternative-fuel vehicles on the road, whether they are today's gas-electric hybrids, vehicles powered by internal combustion engines running on substances other than gasoline or fuel cell vehicles, is critical to reducing the United States' dependence on foreign oil and reducing the amount of greenhouse gases being released into the environment from automobiles.

"It really breaks down to sustainability. Only 12 percent of the world's population has a vehicle now, but we are seeing a big change in that in other parts of the world, like China," said Tim Vail, director of business development for fuel cell activities at General Motors. "We are all for people buying more cars, but from an environmental and petroleum perspective, we cannot sustain this level of growth without doing something."

The United States is already in a situation where our leaders are uncomfortable with our dependence on foreign oil. There is enough concern that the auto industry is taking notice. "While oil reserves appear to be adequate, we anticipate that economies in developing countries will continue to grow at an accelerated rate thus driving up oil demand and oil prices," said Hyundai spokesperson Oles Gadacz.

The situation, both from an environmental as well as a supply perspective, is so concerning that developed countries are shifting their focus to alternatives. Most agree that the logical path for the world's vehicles eventually leads to fuel cells and, as a result, our federal government is working with the auto and energy industries to ensure the shift happens.

President Bush, in his 2003 State of the Union Address, proposed a federally funded program designed specifically to research how to produce, distribute and store hydrogen for use in fuel cell vehicles. This program was in addition to an already existing federal program called FreedomCAR (Cooperative Automotive Research). FreedomCAR is an effort by DaimlerChrysler, Ford and General Motors in partnership with the federal government to develop emission-free and petroleum-free passenger vehicles that began in 2002.

The federal government has committed $1.2 billion over the next five years to its Hydrogen Research Initiative with the goal of bringing hydrogen and fuel cell technology from the research phase to the showroom. Unlike FreedomCAR, which only is open to the American automakers, this initiative is open to Japanese and European manufacturers, and government officials from those countries have reciprocated by allowing the U.S. to participate in their programs. The Hydrogen Research Initiative was kicked off in April with $350 million in initial funding for projects that involve over 30 lead companies and 100 partner companies.

The Department of Energy, which oversees the program, has set the goal to make a decision by 2015 as to whether fuel cell technology is viable. Even if the decision is to move forward, gasoline-powered vehicles will most likely remain in use for many years. "The gasoline-powered internal combustion engine is not going away anytime soon," said John Sakioka, director of Ford's sustainable mobility technologies and director of the FreedomCAR initiative. "But for the first time in 100 years, there are potential alternatives that offer an opportunity to substantially increase fuel economy and reduce or eliminate emissions without sacrificing any of the features that customers want."

How Fuel Cells Vehicles Work

In order to grasp the technology issues the auto industry is facing, it is important to understand how a fuel cell vehicle operates. A fuel cell vehicle is essentially a hybrid vehicle that operates in a way similar to today's hybrids, such as the Honda Civic Hybrid or Toyota Prius. It is powered by an electric motor, which gets its electricity from a fuel cell stack, instead of an internal combustion engine as in the Civic Hybrid and Prius. Whereas the internal combustion engine gets its energy from gasoline, the fuel cell stack gets its energy from hydrogen. The hydrogen is combined with oxygen in order to generate the electricity, which is in turn fed to the electric motor.

Today's hybrid vehicles get their power from both the electric motor and the gasoline engine. Although some can run on one power source alone, all use both the motor and engine in tandem to provide the driver with the extra oomph he or she needs in certain driving situations, such as when passing another vehicle or climbing a hill.

Similarly, fuel cell vehicles can use the fuel cell stack alone to power the motor, but most use a second device, either a battery or a capacitor, to assist the fuel cell stack so the vehicle performs well in these more demanding driving situations. The low-end torque that I admired during all of my experiences driving fuel cell vehicles is partially the result of the batteries or the capacitor (depending on the vehicle) having the unique capability to exert its energy much more efficiently than an internal combustion engine. The effect is more power, in terms of more rapid acceleration from a stop, with far less energy expended.

Inside the Fuel Cell

Just like there are different types of internal combustion engines, there are different types of fuel cells. All use a pair of electrodes, one with a negative charge and one with a positive, and have some substance that generates electricity in between them. Regardless of the type of fuel cell, all are much more efficient than internal combustion engines. The most efficient internal combustion engine has about 30-percent efficiency, meaning that 70 percent of the energy generated is lost. Fuel cells, on the other hand, get between 40- and 70-percent efficiency. According to the National Hydrogen Association, the amount of energy produced by hydrogen is about three times more than a comparable amount of gasoline and about seven times more than coal.

NASA is the federal agency with the greatest expertise in fuel cell technology, which it uses on the space shuttle, among other projects. It uses alkaline fuel cells most frequently because they are highly efficient (about 70 percent), but this type is too expensive to use in automobiles.

The phosphoric acid fuel cell, which is about 40 percent fuel efficient, has seen the most commercial development, while other fuel cell types are still being researched heavily. Researchers are also exploring the molten carbonate fuel cell, which can generate energy from coal-based fuels, and regenerative fuel cells, which use solar energy to separate water into hydrogen and oxygen.

The fuel cell type that looks most promising for automobiles of the future is a Proton Exchange Membrane, or PEM for short. The way a PEM fuel cell generates its energy is actually quite simple — if you think back to your high school science class and the scientific law of attraction.

"There are other technologies, but almost all the automakers seem to be gravitating toward the PEM," said GM's Vail. "PEM is highly suited for automotive applications, and we have the efficiency we need. Now we can make it competitive with the internal combustion engine. The final area is cost; it's still high, but we at GM see a way to get that down."

A PEM fuel cell is comprised of two plates with a catalyst-coated plastic membrane in between. There are channels in the plates, which allow hydrogen (the fuel) and oxygen (from the air) to pass through on either side of the plastic membrane. The atoms in the hydrogen and oxygen are attracted to each other. Each atom is made up of two components — protons and electrons — but only the proton portion of the hydrogen atom can weasel its way through the membrane to join the oxygen. Because the electron can't make its way through the membrane, it must travel on the outside, and this more circuitous route creates energy. This is the energy that powers the electric motor, which in turn makes the vehicle move. Incidentally, when the hydrogen electron meets up with the hydrogen proton and the oxygen atom, it creates the only by-product of a fuel cell — water.

Making Hydrogen

One of the biggest issues facing the auto industry in developing fuel cell vehicles is how to make the hydrogen that gives the fuel cell its energy. Despite the fact that hydrogen is the single most plentiful element in the universe, it is most frequently found as one component of another common molecule, such as water, methanol, natural gas or even gasoline. As a result, the hydrogen must be extracted from this source through a process that breaks the hydrogen out of its bond with the other element or elements. Right now, automakers, energy companies and researchers are exploring various methods and resources for hydrogen production in an effort to determine the most cost-efficient, environmentally-friendly way to provide power for fuel cell vehicles.

One resource being looked at closely is water, because of its wide availability and the fact that it is a "clean" resource. Toyota uses water to produce its pressurized hydrogen through electrolysis, a process that uses electricity as a catalyst to separate the hydrogen from the oxygen in the water. The chemical formula for water is H2O, which effectively means there are two hydrogen atoms bonded to an oxygen atom. Electrolysis separates the hydrogen from the oxygen by breaking the bond between the two elements. Water is just one clean resource for producing hydrogen. Wind, solar energy and biomass (organic plant matter) are other clean resources that are also being studied. "We believe that hydrogen should be made from renewable sources like solar, wind, geothermal or water energy," said Edith Meissner, manager of Technology Communications at DaimlerChrysler.

Currently, though, the most common way to produce hydrogen (which is used as a power source in various industrial processes) is from natural gas, using a steam reforming process to extract the hydrogen from the natural gas. Honda has partnered with Plug Power to create an experimental Home Energy Station at Honda's R&D facility that produces hydrogen from natural gas. The energy station also uses electrolysis and solar energy to maximize its production capabilities, which include electricity and hot water in addition to the hydrogen needed for its fuel cell vehicles.

Honda, like a number of other companies, believes that the eventual solution is for every household to have its own miniature power plant, which provides electricity and hot water for the home as well as enough hydrogen to fuel the household's fuel cell vehicles. Scott Samuelsen, director of the National Fuel Cell Research Center at the University of California in Irvine, envisions this solution as well. "It's possible today to refuel a compressed natural gas vehicle in your home garage, so there is already a blueprint for a system that could provide both electricity for your home and hydrogen for your fuel cell car," he said.

Admittedly, the idea of an energy station in every home is a Jetson-like concept that is still probably a long way from fruition. The sheer logistics of retrofitting existing homes and building new homes with this feature present a tremendous challenge, as does the idea of harnessing hydrogen from any of the clean, renewable resources. "Given the fact that most hydrogen today is formed from natural gas, getting to a point where we use renewables to produce hydrogen is a long road," said Honda's Ellis.

Water, wind, solar and biomass are all possibilities for generating some of the hydrogen supply the United States might likely need, in much the same way these clean resources provide some of our electricity now. And while the home energy station may be commonplace in the future, a short-term solution is needed.

One possibility is extracting hydrogen from some of the fuel sources we use in vehicles now, such as gasoline, ethanol or methanol. This can be done at a manufacturing facility, much the way we see with gasoline today, or it can be done onboard the vehicle, by running the source fuel through a unit called a reformer.

At first glance, the idea of a reformer that uses gasoline looks promising. It would allow drivers to refuel their vehicles by visiting a fuel station the way we do today, so it eliminates the need for an infrastructure of hydrogen fueling stations. There are a number of problems with this idea, however. First, it does not decrease our dependence on fossil fuels and, second, it does not resolve the environmental issue of reducing greenhouse gases.

Perhaps even more critical from a consumer's point of view, reformers currently take a long time to produce enough hydrogen to simply be able to pull the car out of the driveway. Most consumers don't want to compromise on any of the features they enjoy in their vehicles today. So waiting for the car to "warm up" is likely to not be very appealing. One company, Velocys, has developed a reformer that can extract hydrogen much more quickly, but it is currently far too large for automotive use. If the technology can be perfected in a smaller package, then using an onboard reformer is a possible short-term solution.

Producing hydrogen is also more expensive than producing the same amount of gasoline in terms of driving range. According to the National Research Council, extracting hydrogen from natural gas (the most common method currently) costs anywhere between $3.60 and $7.05 per kilogram. New research, however, suggests that using ethanol, which comes from corn, as the source could be the cheapest production method yet.

A group at the University of Minnesota has found that a device that passes a mixture of ethanol and water vapors through a ceramic plug embedded with rhodium and ceria metals produces hydrogen in large quantities. The system is much smaller than other reformers thus far and would produce hydrogen at about $1.50 per kilogram. What's more, the result is about as environmentally-friendly as you can get: the by-products of the process, carbon dioxide and water, are absorbed by the corn crop that is being grown to produce more ethanol. The catch is that the National Research Council believes at least 40 percent of all of the United States' crops would be needed to produce enough ethanol to support Americans' driving habits. That amount is simply way too high.

Whatever the short-term solution, the focus is ultimately on producing hydrogen cleanly. "From a well-to-wheels perspective, hydrogen generated from renewable sources, or with carbon by-products sequestered, is clearly the most attractive fuel option, and fuel cells are the most energy-efficient technology for converting hydrogen into mobility," said Ford's Sakioka.

Storage Problems Mean Short Range

Another issue facing the industry is how to store enough hydrogen within a vehicle to provide a cruising range similar to the 300- to 350-mile range we see on today's cars. At best, the driving range of any fuel cell vehicle in existence today is about 150 miles. These vehicles run on pressurized hydrogen. In theory, to increase the driving range, you simply have to put the hydrogen under greater pressure, which allows more of it to be stored in the same tank. But as you can imagine, the concerns for leakage and other problems under regular driving conditions and, especially, in the event of an accident, grow as the pressure the hydrogen is stored at increases.

Despite the bad reputation hydrogen got over the 1937 Hindenburg accident (although it was recently determined that hydrogen was not the cause), hydrogen has about the same level of safety hazards as gasoline, with the biggest difference being that it burns cleanly, meaning you cannot necessarily set it on fire. A greater issue, according to automakers, is meeting city, state and federal governments' codes and standards for working with hydrogen.

"It's definitely a huge challenge, but it's not that surprising," said Toyota's Reinert, who worked closely with the city of Torrance, Calif., to build a garage for its Toyota FCHV fleet, as well as a hydrogen-fueling station on its property. "Imagine the litigation we'd have if attorneys saw automakers joining together to introduce gasoline today." The storage issue, in fact, is viewed as so important in terms of the viability of fuel cell vehicles that the Department of Energy has asked Congress to almost triple what it has allocated for research and development of hydrogen storage tanks.

The fuel cell vehicles I drove all stored hydrogen at 5,000 psi, and automakers are experimenting with going up to 10,000 psi. The higher pressure can allow a driving range of around 300 miles, which is encouraging. Housing the hydrogen in these tanks, however, is still extraordinarily expensive, with tanks running $20,000 each and more. Further, a study by Argonne National Laboratory indicates that the process of extracting hydrogen from natural gas and compressing gaseous hydrogen into a fuel cell vehicle's tank produces more soot particles and nitrogen oxide than the process of refining gasoline.

Other forms of hydrogen are also being studied. ECD Ovonics is pursuing storing hydrogen in a solid form. It is safer in this form than gasoline, in that it can be handled, spilled and even crushed without harming humans, water, soil or air. The company has a Toyota Prius that it has retrofitted to run on solid hydrogen with success. Currently, however, the range of that vehicle is still only about 150 miles.

Liquid hydrogen is another possibility, but it requires storage at very cold temperatures, which causes still more issues, and research indicates that it does not have the environmental advantages of the other forms. Many automakers are looking at liquid hydrogen as a possible fuel for fuel cells, but BMW and Ford are pursuing this technology for use in an internal combustion engine. Ford sees hydrogen-powered internal combustion engines as a step on the journey to fuel cell vehicles.

BMW is pursuing fuel cell technology as an energy source for buildings (including at its dealerships in Germany) and for auxiliary power in automobiles, but it believes liquid hydrogen is the answer to power its vehicles. "We will bring a hydrogen-fueled internal combustion engine to market sometime in the current generation of the BMW 7 Series," said Tom Purves, chairman and CEO of BMW North America. "Clearly there are a lot of external factors for this to happen, such as fueling stations," he added. A fleet of hydrogen-powered 7 Series vehicles have already been in testing for several years, and BMW has been pursuing liquid hydrogen technology for over 20 years.

Daimler-Benz explored the liquid hydrogen internal combustion engine between 1974 and 1989, showing concept vehicles at auto shows and conducting on-road testing. "After the field test, the company decided to pursue fuel cell technology with hydrogen because of the higher efficiency compared to the internal combustion engines run on hydrogen fuel," said DaimlerChrysler's Meissner.

A Hydrogen Fueling Station on the Corner

The final challenge along the path to fuel cell vehicles is the infrastructure that would allow fuel cell vehicles to be refueled conveniently and quickly. One of the primary reasons that consumers did not accept electric vehicles is that the vehicles took hours to recharge and charging stations were not widely available. The good news is that the refueling process for fuel cell vehicles is already comparable to refueling a gasoline-powered car today. The Toyota FCHV I drove took about five minutes to refuel and the process was akin to fueling at any gas station. There was a fairly typical-looking fuel pump, with a few buttons and levers that activated the system. The nozzle that dispensed the hydrogen was designed to form a seal around the filler pipe, instead of the spout-style nozzles on gasoline pumps we normally see. It was pretty straightforward and not at all intimidating.

The bad news is that putting a fueling station that dispenses hydrogen on every corner is no simple task. "The infrastructure and local codes and standards that permit the operation of hydrogen vehicles are going to be critical to the success of any future hydrogen transportation system," said Ford's Sakioka. "Somehow, the timing of the hydrogen infrastructure needs to be coordinated with the timing of the arrival of hydrogen-fueled vehicles."

What may make all of this come together are two things: one, that many cities already have hydrogen pipelines underground which deliver hydrogen for industrial use and, two, that many gas stations are already set up to dispense compressed natural gas using a system that could be easily modified to dispense pressurized hydrogen.

"Houston is just one city of many that has a hydrogen pipeline," said GM's Vail. "Fueling stations could be built off of those pipelines pretty easily, while in rural areas I think you'll see on-site production using natural gas to begin with because it is cost-effective and relatively clean."

Several hydrogen fueling stations have already been built to fuel the current fleet of fuel cell vehicles and more are on the way. Shell is in the process of converting one of its stations in Washington D.C. to dispense hydrogen for a fleet of General Motors' fuel cell vehicles that are part of a demonstration project there. Plans are also in the works to build a network of fueling stations in California, Florida and the Northeast as part of the initial group of projects funded by the president's Hydrogen Research Initiative.

The Los Angeles International Airport will be the site of the first compressed-hydrogen fueling station open for public use. The $1.5 million facility built by Praxair will be a prototype of a commercial automobile fueling station and is slated to open this year. California governor Arnold Schwarzenegger is putting together a plan to build a "Hydrogen Highway," an effort that is supported by the California South Coast Air Quality Management District and the California Fuel Cell Partnership, a private-public venture dedicated to demonstrating fuel cell technology in the state. Founded in 1999, the partnership has both passenger cars and transit buses in its fuel cell demonstration fleet, including vehicles from DaimlerChrysler, Ford, General Motors, Honda, Hyundai, Nissan, Toyota and Volkswagen.

One of the projects funded by the president's initiative will result in the construction of as many as 24 hydrogen fuel stations in California alone over the next five years. This project, which involves BMW, Honda, Nissan and Toyota, as well as energy company ConocoPhillips and several universities, will experiment with multiple approaches to producing hydrogen and creating fueling infrastructure, including building fueling stations along an existing hydrogen pipeline, at current retail gas stations and in municipal locations. Some stations will dispense both gaseous and liquid hydrogen.

The key to the infrastructure issue, at least initially, is natural gas, according to the National Fuel Center Research Center's Samuelsen. "Natural gas will be the principal source of hydrogen in the near to medium future," he said. "Natural gas is already piped into most [gasoline] stations, and it's a very straightforward procedure to put hydrogen through those pipelines. On-site generation would likely only be in areas that were remote or couldn't be placed along a pipeline."

While on-site production of hydrogen could be done a myriad of ways, size of the generation facility is a concern. The hydrogen generation machine currently in development by H2Gen Innovations is an encouraging first step. The company's prototype machine is about the size of a commercial garbage dumpster and it can produce enough hydrogen to fill 160 fuel cell cars a day. That's pretty close to the 175 vehicles the average gasoline station supplies daily. As with most new technologies, the cost of the system is high — about $375,000 per machine — but H2Gen is working to cut the price by about 50 percent, which would help to provide a solid business case for adding them to some of the existing network of 173,000 gas stations in the U.S.

Real-World Experience

Although fuel cell cars are decidedly still in the research phase, there are quite a few fuel cell vehicles in daily use throughout the world, being driven by typical consumers, versus those associated with an automaker or supplier. In December 2002, Toyota put two fuel cell vehicles into daily operation with the assistance of the University of California's Irvine and Davis campuses, while Honda just celebrated its one-year anniversary of a leased FCX to the City of Los Angeles.

The FCX in fact became the first fuel cell vehicle certified by the Environmental Protection Agency (EPA) in November 2002. As part of the testing at the EPA's National Vehicle and Fuel Emissions Laboratory in Ann Arbor, Mich., the EPA established fuel economy for the FCX that is the equivalent of 52 mpg on the highway and 49 mpg in the city. In order to test the vehicle, the EPA needed to adapt its processes as well as the facility in which it tests the vehicles. Joe McDonald, co-leader of the hydrogen and fuel cell team at the EPA's Air Quality Assessment and Standards division, said that the testing procedure was similar to testing today's gas-electric hybrids in that "we monitored the energy storage device for the state of charge, meaning the current that was produced from regenerative braking to the battery and from the battery to the drive system." All in all, McDonald described the fuel economy data as "not surprising" and noted that its numbers matched the testing done at Honda's own facility within one percent — impressive considering that fuel economy testing of fuel cell vehicles is in its infancy.

The number of fuel cell vehicles on the road being driven by "real" people is steadily increasing. Honda now has a total of seven vehicles being driven daily by city officials in Los Angeles and San Francisco with plans for additional vehicles to be added later this year. A DaimlerChrysler F-Cell vehicle began getting daily real-world testing as a United Parcel Service delivery vehicle in Ann Arbor in April.

Driver Charmaine Farrell, a driver with UPS for eight years, refuels her vehicle at the hydrogen station at the EPA's facility. "I'm not a scientist or an engineer, which shows just how far fuel cell technology is advancing," Farrell said. "It's been a great experience, and I love telling my customers that their package was delivered with zero emissions."

Toyota has had two of it FCHVs on the road for over a year and recently added two more to its "real-world" fleet, with plans for additional vehicles in the near future. Gregg Kelly, president and CEO of Orthodyne Electronics, has been driving a Toyota FCHV since December 2002, through a lease-program that is part of Samuelsen's National Fuel Cell Research Center and has logged about 7,000 miles using it as his daily driver. Kelly, who previously drove an Audi A6, said that his driving experience has been basically like driving a gasoline-powered vehicle, with the exception that the right-hand drive setup took about a week to get used to. "It takes about four minutes for it to warm up to full power, but it's not a big deal. [Toyota] actually had to bring it to my attention that this was the case," he said.

With a 120-mile range and only one place to refuel nearby, Kelly finds that his trips do require some forethought. "In a regular gasoline car, there's very little planning involved. With this, you have to be thinking about what you are going to be doing that day, but I expect that will change as more hydrogen stations open and as the technology is able to increase the (driving) range."

What's a bigger issue, Kelly said, is the lack of engine noise. "It is very quiet, so sometimes it is hard to be aware of your speed. The quietness is also an issue with people on foot, like in a parking lot," Kelly said. "I've had people look right at the car while I'm driving in a parking lot and then step out in front of me. I've seen it with animals, too. I never realized how much we associated noise, versus movement, with danger."

The quietness is an issue on the minds of many in the auto industry, including Toyota's Reinert. Fuel cell vehicles are, he said, "too quiet and we need to assess that carefully. We've learned that there can be issues in situations where cars are sharing the road with pedestrians or bicyclists and as an industry we'll need to address that."

Neal Harvey, senior vice president at Horiba Instruments, is driving the second Toyota FCHV that is leased through Samuelsen's National Fuel Cell Research Center. His vehicle, a left-hand drive model, had only been in his hands a few weeks when I spoke with him. Harvey, who most recently drove a Lincoln Continental and a Porsche 911 had adapted easily, although he also commented that he, too, occasionally startled people with the vehicle's quietness. "It is very easy to forget you are driving such a unique vehicle," he said. "It is almost seamless to go from today's (gasoline-powered) vehicles to a fuel cell car."

Next Steps

The real-world research thus far is helping to further the development of fuel cell vehicles, and over the next five years, a couple hundred fuel cell vehicles are likely to make their way to our nation's roads as part of the president's Hydrogen Research Initiative. Just the same, it will be quite a while before we find fuel cell cars at our local dealerships, and when we do, they will likely be sold alongside traditional gasoline-powered vehicles and gas-electric hybrids — at least initially.

"Our crystal ball is no clearer than other experts', but we tend to agree with the U.S. Department of Energy's timeline, which identifies 2015 as a reasonable timeframe for the auto and energy industries to move forward on developing the products and infrastructure and make the commercialization decisions," Ford's Sakioka said.

"It must also be remembered that gasoline will not disappear overnight, and as we've seen with our SULEV technology, gasoline cars can be very clean," Nissan spokesperson Sumi Shimizu noted.

Oil and gas are likely to remain the dominant energy sources until somewhere around 2040, according to a study conducted by Royal Dutch/Shell, although the study did indicate that fuel cell vehicles could account for 25 percent of new auto sales in industrialized nations as early as 2020.

"Our goal is to have fuel cell vehicles available in the beginning of the next decade, assuming the infrastructure happens as well," said GM's Vail. "It could be as early as 2010 or 2012 that we begin to have them available. Depending on the infrastructure, it is entirely possible that there might be other countries (other than the U.S.) that get fuel cell vehicles first."

The years between now and the time fuel cell vehicles arrive in showrooms will be a time of education, both within the industry as well as with the consumers who will eventually be able to buy these vehicles. "With every person who drives an alternative-fuel vehicle, whether it be a hybrid, a compressed natural gas car or a fuel cell vehicles, we are building a class of apprentices who will help to bridge the gap between today's internal combustion cars and the cars of tomorrow," said Honda's Ellis, as I pulled back into the driveway of the hotel.

When the valet came around to open my door, I looked at his warm brown eyes once again, wondering if he had any idea he was in this elite group of apprentices. "It's running," I said, taking the claim check from him.

"Yes, ma'am, I know," he replied as he slid behind the wheel.