Installing a new clutch will likely only be done once during the life of your vehicle. The clutch should typically last at least 100,000 miles if driving under normal conditions. The clutch plays an important role in the operation of your vehicle. When the clutch is pressed, power is transferred from the engine to the transmission. The correct gear is selected and the clutch is released, allowing the car to continue down the road at a different engine speed.

Remove the transmission from the engine. Support the engine using a jack with a piece of wood between the jack and the oil pan to distribute the weight or use an engine hoist.

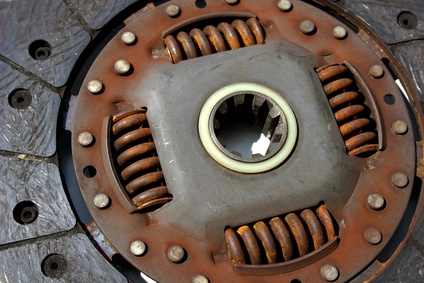

Inspect your clutch kit to make sure you have all required parts. Kits should include a pressure plate, clutch disk, throw out bearing and a clutch alignment tool. The kit might also include a pilot bearing but if it does not, purchase one separately.

Remove the original pilot bearing with the pilot bearing removal tool. Insert the new pilot bearing into the crankshaft with the two notches facing inward. Press a flat, metal surface against the pilot bearing and gently hammer into place. The new bearing should be completely flush with the outer edge of the crankshaft.

Clean the new flywheel and pressure plate with brake or carburetor cleaner. Install the new flywheel with the flex plate behind it by putting Loctite on the bolts and torque them down at 85 ft/lbs.

Install the 3 dowels from the racing kit into the non-threaded, tapered holes on the flywheel. Place the clutch disk on, holding it in place with the alignment tool from the clutch kit. Install the pressure plate over the clutch disk by putting Loctite on the bolts and torquing them down to 24 ft/lbs. The clutch disk and the pressure plate will slide over the 3 dowels placed on the flywheel.

Attach the transmission to the engine, being very careful to line up the splines. Do not force the transmission onto the engine. Use Loctite on the bolts and torque them to 38 ft/lbs. The clutch might need minor adjustments within the first 500 miles.