The knock sensor is a component in the engine of your car designed to detect pressure levels. It is near the pistons or the intake manifold and acts as a listening device of sorts because it records vibrations. The data that it records is sent to the car's computer to determine whether the engine is operating efficiently or whether it needs to adjust the ignition timing. A faulty sensor can cause engine problems and result in engine knock.

Engine knock is a sound the engine produces when pressure is applied to the gas pedal if the fuel/oxygen mixture is exploding too quickly inside an internal combustion engine. If the timing of the combustion is off, the spark plugs or the pistons can rattle and the engine can start shaking and result in a hollow knocking noise called engine knock. Sometimes it will sound like more of a rattle. This can damage the engine and result in poor fuel economy, acceleration problems and other engine-related difficulties.

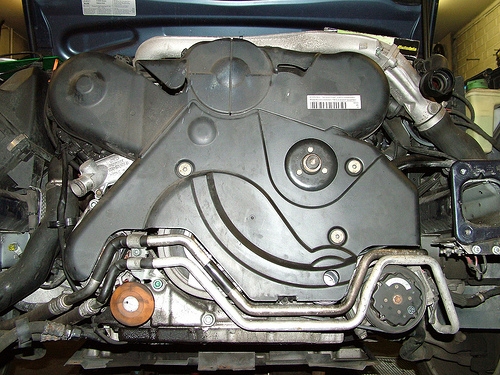

The knock sensor's main component is a piezoelectric element. It has a coil wrapped around it and a wire that connects the sensor directly to the car's computer. When the sensor vibrates, it sends electric current through the wire to the computer, which then interprets the reading. The sensor acts like a listening device and is inside the engine near the intake manifold or the pistons. It detects pressure inside the engine. The vibration that it records is converted into voltage that is then sent to the computer, which then can alter the engine timing accordingly to prevent the engine from knocking and keep it running smoothly.

If the knock sensor starts to fail, repairing it is not really possible and the sensor will need to be replaced. It can take a lot of time and a mechanic should do it for you unless you are very familiar with engine work. Some models have the knock sensor stored inside the engine block and the radiator coolant would need to be drained as a result. Refer to your owner's manual for the specifics on your engine because the sensor must also be torqued to exact specifications. If it isn't, it will be too sensitive to vibration and harm engine performance or it may not work at all.

Some knock sensors are also designed to assist the engine in reaching peak performance by getting the engine right up the point of knocking and then dialing down slightly to keep it just underneath the knock point. This results in greater power and acceleration performance from your vehicle. The knock sensor also helps your car maximize fuel efficiency and can save you money on gas when it is working properly.

Follow your car's instructions regarding what type of gas to put i, because the wrong octane could affect the knock sensor's performance along with the rest of the engine. The sensor is VERY sensitive to vibration, so if you are putting in a new one, be quite careful with it, because if it drops, it is very likely to break outright and not function. The seals that protect the sensor can sometimes get dried out and cracked from extreme weather conditions and this can allow moisture to seep into the sensor and cause it to short. A mechanic can run a test on the sensor to determine whether it is properly torqued and working correctly.