Testing automotive electrical components is a necessary facet of determining which parts are at fault when an electrical problem arises. Not all electrical problems are obvious or easily spotted, and many problems cannot be found by visual inspection alone. Testing for electrical problems requires a methodical approach as well as following some basic tips in order to simplify the process as much as possible.

Determining the source of electrical problems in automobiles is best performed in an organized manner. A preplanned procedure will aid in isolating faulty components and reduces the chances of missing an obvious problem. Work should be performed systematically, with each possible cause of the problem examined fully before moving on to the next possible source. As each component is checked and eliminated as the source of the problem, the list of possible causes will then be narrowed down until the actual problem is found.

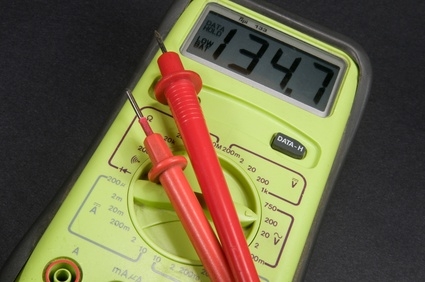

Testing automotive electrical problems requires at least three basic tools. A test light is necessary to check for the presence of power at connections and components that you suspect might have problems. Jumper wires are necessary for isolating components that might be the source of the problem. Jumper wires allow power to be directly connected to a component, or a component can be bypassed, depending on the problem being examined. A multimeter is necessary for testing for the presence of the proper voltages and ohms at a component, which can reveal if the problem is with the component or the power being supplied to it.

Some of the most common electrical problems in automobiles stem from bad grounds. The entire electrical system in an automobile is dependent upon a solid negative ground to create an effective closed circuit. Poor grounds in this circuit can result in a wide variety of difficult to diagnose electrical problems. Any negative ground connections between the electrical system and the metal body of the vehicle should be inspected and cleaned or repaired if necessary before beginning in-depth troubleshooting of the electrical system.

Poor connections in the electrical system are another of the most common problems encountered when troubleshooting automotive electrical problems. The battery, alternator, and wiring harness connectors are the most common sources of poor connections and should be carefully examined for damage and corrosion and repaired if necessary.

Some components of an automobiles electrical system can produce very high voltages that can be extremely dangerous to work around. All electrical troubleshooting should be performed using the proper safety equipment, such as protective eyewear and gloves. Automotive batteries can produce explosive gases and care should be taken when working near the battery to avoid creating sparks or open flames that can ignite these gases.