The '00 Wrangler into which the UNO stroker was fitted. The latest report is that this engine will pull the front wheels on a full power launch and has the grunt to lug over the tallest rocks with aplomb. On the highway, it can pull the West Virginia and Pennsylvania hills in Fifth gear with no trouble.

The '00 Wrangler into which the UNO stroker was fitted. The latest report is that this engine will pull the front wheels on a full power launch and has the grunt to lug over the tallest rocks with aplomb. On the highway, it can pull the West Virginia and Pennsylvania hills in Fifth gear with no trouble.

Last month, you got the skinny on stroking the 4.0L Jeep inline Six. Now you'll get to see it in action and learn about all the goodies we bolted onto the outside.

You'll see and hear varying numbers on what power and torque the various stroker conversions produce. Many we've seen on the Web were derived from "desktop dyno" computer programs, which we have usually found to be on the optimistic side. Some claims are derived from actual dyno tests, most via chassis dynos. Chassis dyno numbers can be subject to a lot of error and are most useful for before-and-after testing to see a percentage of improvement rather than determining raw, useful numbers. Our tests were performed on a highly calibrated, state-of-the-art engine dyno by Technical Services, whose major operation is fuel-injection R&D for the major vehicle manufacturers, race teams, and crate engine manufacturers.

Technical Services is one of those behind-the-scenes companies that will develop systems and products for other companies to use and tout. Especially when dealing with the OE manufacturers, they have to be accurate to the proverbial gnat's bootie. The numbers we got are accurate and a real representation of what our particular combination of parts will deliver, with no particular products to sell and no motive other than passing along results.

We were also aided by Quadratec, Craig Jaros in particular, who provided parts for testing. Quadratec is one-stop shopping for Jeepers, with all the major brands represented, and its willingness to provide parts for testing purposes helped get the University of Northwestern Ohio (UNO) engine running like a top.

By the time the UNO High Performance Machining Class had finished, we had an engine that was, for all intents and purposes, blueprinted. That's probably a higher standard of work than most people can afford, but select portions of it are within reach of all. Balancing is one. The ARP rod bolts are another. The rest is not beyond a machinist who takes his time-time you'll pay for. Our UNO students took the extra steps of align-honing the crankshaft saddles and boring the cylinders perfectly perpendicular to, and decking the block perfectly parallel with, the newly aligned crankshaft bores. None of that will add all that much to the power output, nor to engine life, but it was cool and good training. Let your paycheck be your guide.

We knew we were starting off with the worst H.O. head of the three types available, but the UNO class was determined to make it better. The work started with airflow tests of the stock head (see page 69) on the UNO's Superflow 600 flow bench, and they largely matched other tests we've seen published.

The ports were massaged according to the generic formulae that work for all heads. Nothing radical was attempted, but the exhaust ports were enlarged to match the earlier size; the valve guide bosses were made more flow-friendly; and the port walls were smoothened. After the ports were done, a five-angle valve job on the school's Sunnen seat grinder was performed. You've all heard about the three-angle valve job, and the extra angles are further enhancements to airflow.

The end result on the flow bench can be seen on page 69, but some of the gains showed up on the dyno in an unusual way. Technical Service's top-drawer dyno can measure airflow and volumetric efficiency (VE). This is the theoretical amount of air an engine of a given displacement would use versus what it actually can use. In the old days, 80 percent was really good. Nowadays, 85 to 90 percent is fairly common. Our engine was at 85 percent at under 2,000 rpm, over 90 percent at 3,000, and hit 100 percent at 3,500 and climbed to a high of 103.4 percent at 4,500 rpm. Part of that was due to the head, and part was due to the ram-tuning effect of our 2,000-and-up intake manifold.

Last month, we spoke extensively on how important cam selection is for the stroker and mentioned that we had chosen a Crane 753905 cam, with .456/.484-inch cam lift and 204/216 degrees duration at .050-inch lift. We installed the recommended unit (PN 99833) with 95-pound valve springs and Crane lifters. Our past experience has shown this is a great cam in the 4.0L. Crane recommends a 9.0:1 to 9.5:1 SCR with it, and we were at the upper end of that recommendation.

After looking at the dyno results and some others, we think we could have used more cam. If we were doing this again, we'd have installed the hotter Crane 753941, which has .484/.512-inch lift and a 216/228-degree duration. We wouldn't have lost any low end to speak of, but would have gained in the mid-range and upper end and reduced the possibility of pinging. As it is, the engine is ping-free on premium fuel and will run on mid-grade or regular with light loads. The hotter cam would likely have made this engine a regular fuel user.

We installed Quadratec's spectacular roller rocker setup. At the time we started the project, Quadratec had just debuted these beauties. We glommed on for many reasons. High-lift cams will increase the wear on the valve stems and guides by inducing more side loading. This side loading increases with increased lift, and the roller rockers reduce it to zero. The roller rockers also reduce internal friction and oil temperatures.

Any stroker will require some mods to the fuel injection. That stands to reason because of the increase in displacement. The most important step is to increase the size of the fuel injectors. Injectors are rated by fuel flow in pounds per hour (pph) or cc's. Power output is limited by the injectors' maximum flow. The OE manufacturers size them with little reserve. That's the smart thing to do, because to finely control them at low speeds and meet emissions standards, they can't be too large.

We proved that 24pph injectors would provide the fuel flow we needed to avoid running lean at higher speeds but would also be controllable at the bottom end and have an 80- to 85-percent duty cycle-the amount of time the injector is activated. An occasional short spurt over 80 percent is not necessarily harmful, but if you need to consistently run at or over 80 percent just for normal work, you'll have trouble. Many stock-type injectors will overheat and "fibrillate," or even fail, if consistently operated at high duty cycles. Also, if the unit is running at near 100 percent, there is no reserve for those moments when the engine needs to run richer momentarily to avoid a potentially damaging lean condition.

To answer your next question, yes, increasing fuel pressure will increase fuel flow. Injectors are rated by the amount of fuel they deliver at a given pressure, either 39 or 49 psi for 4.0Ls depending on year. Raising fuel pressure is a useful tool for fine-tuning but is also a popular band-aid for lots of problems with better answers. An injector rated for 21 pph at 39 psi will flow 22 pph at 49 psi.

The problem is that a particular injector is designed to operate at a given pressure and it's more difficult for it to open against higher pressure. Not only that, the high pressure will increase pressure spikes in the fuel rail. These come when the injectors close and fuel pressure momentarily spikes a lot higher until the fuel pressure regulator can react. What happens when another injector is trying to open just as pressure spikes? It may not get fully open and momentarily starve that cylinder for fuel. That's not only bad for power output-it can cause damage.

As paragons of EFI, we got some valuable training at Technical Services. As part of the learning process, they went one step further by building us a programmable EFI system that was tuned for our engine. It consisted of GM-based parts, a Delphi module and coil driver. They spent the better part of a day custom programming before running our "for the record" dyno test. Little did we know at the time that our project provided some R&D for them to help Painless Wiring develop a stand-alone system for Jeep 4.0L engine conversions (more on this later).

A stand-alone programmable system isn't necessary for the average stroker. We "unconverted" ours, going back to the standard EFI, and it still runs incredibly strong. Generally speaking, a 24pph injector will suit most strokers along with an adjustable MAP (Manifold Absolute Pressure) sensor. Another useful tip is to move the IAT (Intake Air Temperature) sensor into the airbox from the relatively hot intake manifold. An adjustable fuel-pressure regulator is useful for fine-tuning. All that said, you may need more or less than that, depending on your setup, and we can't cover it all here. The ideal, of course, is a stand-alone programmable system tuned specifically for the engine as built.

A replacement exhaust was a given. On the intake side, we had the fantastic new-style intake working for us. This is an equal-length runner setup with a large plenum that appeared on the '99 WJ and on everything else in 2000. We added a larger (62mm vs. 58mm stock) Rock-It throttle body and AEM spacer (included with the AEM Brute Force cold-air kit) but we were not sure if we needed them. The stock throttle-body flow was around 450 cfm of air, according to our sources. According to the airflow monitors, our engine was using only 383 cfm at its peak rpm.

Is a stroker emissions-legal? Maybe. Is it a replacement engine or a modified engine? In those places with stringent standards, you may have a hard sell on the replacement engine part. If all the changes are internal and not visible and the engine passes the tailpipe test (many strokers do), who knows? Our sister publication, Jp magazine, built a stroker for the "Insane Inline" series back in 2005, and it passed the California test with no more than 24pph injectors and a modified timing sensor.

A larger engine, or a larger engine with a higher output, will generate more heat than stock. We addressed that two ways. First came the FlowKooler water pump idea, which has some serious flow improvements over the stock pump. It bolted up to our first block but not to the second one. Unfortunately FlowKooler doesn't offer one for the metric 4.0L block. That left us with a Northern High Performance aluminum radiator from Quadratec and a RobertShaw high-flow 180 degree thermostat.

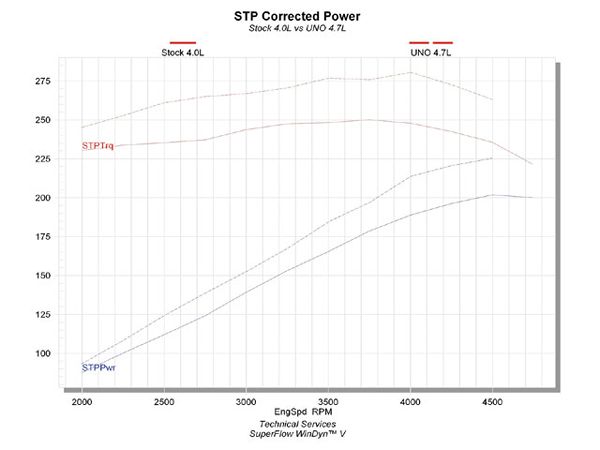

Dyno day was exciting. The engine had been well broken-in during the tuning process. We found out early that our engine was pretty much done at 4,500 rpm. It would rev higher, but the power curve began leveling off and torque began dropping. This was our poor cam choice talking again. On the other hand, that's still well above the rpm range for 99 percent of Jeepers. Plus, it started off at 2,000 rpm with 5 lb-ft more torque than the stock 4.0L and climbed like a rocket. At 2,500, it's over 265 lb-ft where the 4.0L is only at 230. The stroker was within about 10 percent of peak torque from 2,000 to 4,500 rpm.

Even if you take out some of the higher-end additions used on this project, you can see the stroker idea has a lot of merit. It could be a very cost-effective modification if performed at rebuild time. Many of you so inclined might already have the other goodies installed on your 4.0L to enhance it, such as intake and exhaust mods. The important parts to remember are the compression and camshaft-related issues. The rest is a serious breeze, considering the results, and not expensive.

Peak Power: 225.4 hp at 4,497 rpm. Peak Torque: 280.2 lb-ft at 4,002 rpm. The UNO stroker's power and torque curves compared to a 4.0L curve. The 4.0L power curve is actually enhanced somewhat. A stock used engine was fitted with a programmable ECU and "tweaked" for optimal results-for an estimated 5-percent gain over stock. Also, this was not an SAE-rated test, with all ancillary devices, including the exhaust system, hooked up and operating. Both engines were tested to the same standard-the dyno exhaust system-no air filter and driving only the water pump. Installed power would be slightly less.

CYLINDER HEAD FLOW INFORMATIONLift in inches. Rated in cubic feet per minute. Tested at 28 inches of water pressure drop. Results averaged and rounded.Stock Head (casting number 0331)Valve Lift (in).{{{100}}}.{{{200}}}.{{{300}}}.400.500Intake ( )55119173191211Exhaust ( )2982111132141Modified HeadValve Lift (in).100.200.300.400.500Intake ( )70128190211221Exhaust ( )58106127144162Stock Head Flow at Peak Valve Lift

Crane 753905-Intake: 208 cfm @ .456 lift

Exhaust: 143 cfm @ .484 lift

Modified Head at Peak Valve Lift

Crane 753905-Intake: 217 cfm @ .456 lift

Exhaust: 156 cfm @ .484 lift