Hydraulic steering can make or break a trail machine. An inadequate system can over-exercise arm muscles while making tight maneuvers very frustrating. Or, if well designed, a hydraulic steering system can actually contribute to the overall enjoyment of a day in the dirt. That's because the amount of physical effort it takes the driver to turn the steering wheel relates directly to how well the hydraulic system functions. A poorly designed system or even a simple misuse of parts for a particular application can result in sluggish, and hard-to-use steering wheel - not to mention the ill effect on reliability. That's why we decided to delve into the subject of hydraulics and address a few common issues, while at the same time contrasting the two popular types of setups we see on the trail. We're going to break this somewhat complex topic into two categories.

Full Hydro

Traditionally, this has always been the point where most 'wheelers cross the line between a trail-only rig and a daily driver. This is because most people feel hydraulic systems are unreliable and therefore not suitable for the street. However, this is not necessarily true. Take a look at the heavy equipment industry: Caterpillar tractors, for example, rely on a variety of hydraulic systems to function, many of which control directional movement. Hydraulic steering systems have their place in several street-driving scenarios, too, though most are found on industrial or agricultural equipment operated at low speeds. These systems are engineered to perform a specific task within a specific range of parameters (i.e., speed, weight, temperature, and environment). The problem here - and probably part of the reason why fully hydraulic steering gets a bad rap on the street - is due to system design, or lack thereof. It all boils down to economics. No common man is willing to invest the millions it took Caterpillar to develop a fully hydraulic steering system reliable enough to pilot its dump trucks down the road safely. And because there are several sources for hydraulic steering components, all with very little "specific information" about each particular application, it's hard for Joe Consumer to know which widget to install on his own rig. Full hydraulic steering requires eight major components: Each is equally important to the overall performance of the system. That's why it's most important to build a balanced or matched system.

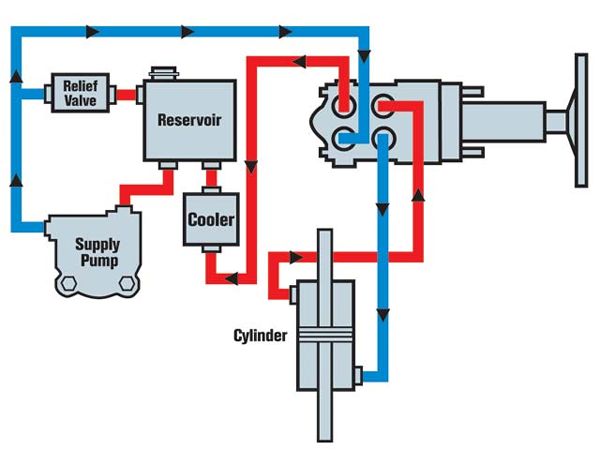

This is a typical full hydraulic steering system.

This is a typical full hydraulic steering system.

Ram Assist

For most 'wheelers, the somewhat less expensive, less complex hydraulic assist may be the best option. In most cases, companies offer complete kits for specific vehicle applications like the PSC kit shown above for the '05 Jeep TJ. With an assist setup, your rig's mechanical steering remains intact, enabling the option of manual steering if the hydraulics should fail. We like this setup for trail rigs that are driven on pavement from time to time. Aside from helping your steering system push around larger meats, a ram assist can function as the ultimate steering dampener, too. At the same time, a ram assist also helps relieve stress on other steering components such as the steering box. The major difference between hydro-assist and fully hydraulic steering is that hydro-assist is basically a piggyback setup you add on to your existing steering system, while a fully hydraulic system is a stand-alone system relying completely on fluid power.

Reservoir

This is the hydraulic fluid (or power-steering fluid) reservoir that stores the fluid necessary for the system. Think of it as an oil pan. Most power-steering pumps have a reservoir attached right to the pump body. The one shown here is a PSC part. At a minimum, the reservoir must be large enough to hold reserve oil for both extended and collapsed cylinder lengths. To figure out what you need, consider the oil volume-to-duty cycle ratio. In heavy equipment, this ratio is roughly 3:1, meaning your reservoir should hold three times the volume of the system. This is probably overkill for our purposes because this ratio was designed for 100 percent duty-cycle applications such as a bucket loader working at a strip mine that runs 24/7 all year long. A Jeep or buggy will typically see use on the weekends for recreational purposes only, so you really wouldn't need a 3-gallon power-steering reservoir. Keep in mind how often you use your rig and how much time the system will actually run once installed. In most cases, the supplier will have two or three different sizes of reservoirs to choose from.

Steering Control Unit or Metering Valve

Similar in function to the automotive "steering box," this part translates driver input at the steering wheel to actual movement of the cylinder. Many people call them "orbital valves." This is incorrect. "Orbital" refers to a specific type of hydraulic motor that has nothing to do with hydraulic steering. The hydraulic industry refers to these as steering control units (SCU) or, more commonly, metering valves. Metering valves have a specific displacement volume, which equates into how many cubic inches of fluid can pass through the valve in one 360-degree revolution. The rule on metering valves is: The higher-volume (in cubic inches) valve you get, the faster the wheels will cycle through the range of movement.

The Pump

Hydraulic pumps convert mechanical energy into hydraulic (pressure) energy. They operate on the displacement principle. Fluid is taken in and displaced to another point. Many different types of pumps exist, and most companies set up power-steering pumps to produce between 3 and 5 gallons per minute (gpm) of flow. The key to finding the right pump is to know the desired effort first. Do you want to turn your steering wheel two or three turns lock to lock? First, calculate the total volume of the system, then figure out how much oil you will need to pass through the metering valve to get the ram to move through its entire range of motion. Once this is figured out, you can calculate how much volume your pump needs to displace.

Here's the formula: Volume of cylinder (ci) volume of metering valve (ci) = turns lock to lock

For example: a Howe 2.5-inch bore x 8-inch-long double-ended cylinder like the one we installed on our project Mega Titan has a cylinder volume of 25.82 cubic inches. The Mega Titan's metering valve has a volume of 7.6 cubic inches, if we do the math: 25.82 7.6 = 3.39 turns lock to lock, which is about all you want on a rockcrawler.

Relief Valve

It's simply a pressure relief pop-off, similar to what you might find on a shop air compressor. If there's a malfunction in the system and the pressure spikes, the relief valve opens and the pressure is released back to the reservoir. This is a wonderful safety mechanism.

Double-Ended Cylinder

This is the hydraulic actuator commonly known as a ram. Technically, they're referred to as nondifferential cylinders, or double-acting piston-type cylinders. They replace the mechanical linkage in a traditional manual steering setup. The size of the ram depends on the mechanical effort that the system requires to steer the tires. Here we believe the most important things to consider are what materials are used to build the ram and how far the manufacturer goes to ensure the ram is perfectly centric. Does it have two thin internal fiberglass shaft-support bushings? Or does it feature a larger 2-inch-long bronze bushing block to support the shaft? Little things like this make a big difference when your wheels are in a bind. Also, is the ram easily rebuildable? We suggest you do some research online before buying. To help calculate how big your cylinder should be, consider this: The force a cylinder can generate is equal to the product of the piston area (sq. in.) and the pressure (psi) supplied by the pump, minus losses due to inefficiencies such as friction and flow restrictions.

Cooler

Just as a radiator exchanges heat from water, the power-steering cooler helps keep the steering system's oil temperature in check. Howe builds two very trick billet coolers that lower oil temperatures up to 24 degrees without restrictions. The units are both durable and compact, and we like the trick-looking mounting brackets Howe supplies to help you secure it to rollbar tubing.

Pressure Line or Supply Hose

These lines carry power-steering fluid to all the parts of the system. The operating requirements for hydraulic hoses are impressive. High-quality hose should be considered a top priority, as the hose is typically the most vulnerable part of the system. All lines must be of the proper size and free of restrictive bends. It's nice to use the do-it-yourself hose kits with screw-tight fittings rather than professionally built crimp-on fittings. This way, all you need is a short length of hose to do repairs on the trail.

Oil

In hydraulic systems, oil performs the dual function of lubrication and transmission of power. It's basically the life blood of a hydraulic system, and careful selection should be made with the assistance of a reputable supplier.

Steering Box

A steering box is used on most 4x4s built today. With the exception of late-model SUVs and some IFS pickups, a steering box is typically mounted on the driver side, along the framerail. The function of a steering box is to translate driver input from the steering wheel into a usable rotational force for mechanical steering linkages. Typically, this is the most complex part of a steering system. Most steering boxes are made from cast iron and have a pretty good life expectancy.

When a steering box gets old, the steering begins to feel loose or sloppy. Most shops have rebuild programs where worn boxes are reconditioned for second and third installations; this is called a core exchange program. Sometimes, a used box is too badly worn to repair and has to be replaced completely.

This picture shows a fully hydrostatic arrangement on the front end of Top Truck Challenger Dan Dibble's ASM rock buggy. In extreme situations, such as rock racing, this type of setup is superior. A POS double-ended ram is mounted high on the front axle. It's very important to get the steering geometry right when building a system like this.

Though the exact placement of the ram varies from axle to axle, there is one key consideration to remember when mounting a double-ended ram: Angle of deflection. The angle of tie-rod deflection is critical to the life of the ram. Too much deflection can cause extreme shaft side-loading and, ultimately, ram failure. The illustrations at right demonstrate an ill-positioned ram as well as a well-balanced mounting method for double-ended ram tie-rod deflection.

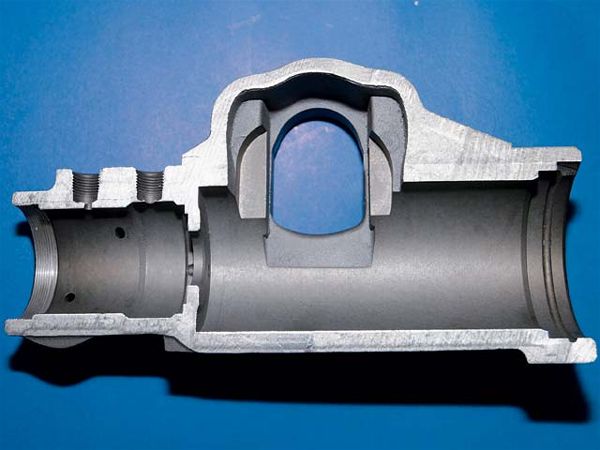

Howe recently stepped up to the plate with a whole new steering box cast entirely from aircraft-quality aluminum. This new box is both lighter and stronger than traditional iron jobs. Additionally, it features hard-anodized wear surfaces for increased longevity. In this cut-away, you can see where Howe taps the casting for hose fittings. This is a great new product because you get a perfect, never-used-before unit instead of a rebuilt box with questionable tolerances.

Howe recently stepped up to the plate with a whole new steering box cast entirely from aircraft-quality aluminum. This new box is both lighter and stronger than traditional iron jobs. Additionally, it features hard-anodized wear surfaces for increased longevity. In this cut-away, you can see where Howe taps the casting for hose fittings. This is a great new product because you get a perfect, never-used-before unit instead of a rebuilt box with questionable tolerances.

Full Hydro

Howe, PSC, and POS all build great full hydraulic systems for 4x4 enthusiasts. However, when you focus in on the details of each setup, you'll find each system is very different, and depending on what type of 'wheeling you plan to do, each system has strengths and weaknesses. For instance, Howe builds a large majority of the steering components found on high-speed Baja racing vehicles, one area where failures can cost lives. Though they do offer a variety of systems for rockcrawlers. Howe made its name in the desert racing community. POS, on the other hand, is a niche-focused company specializing only in fully hydraulic systems for extreme rockcrawlers and buggies. PSC Motor Sports covers all the niches of the industry, though some would argue that its mainstay is professional rock racing. In any case, all three companies have very nice components for just about every budget level.

Hydro Assist

West Texas Off Road, Howe, and PSC all make awesome hydro-assist kits. These hydro-assist setups retain the mechanical functionality of the OEM steering system. For dual-purpose trail rigs, these types of setups are probably the best options. We recently installed the West Texas Off Road system on our project Teal-J. We're very happy with the its performance thus far. Likewise, the Howe ram-assist system we recently installed on our Baja Bomber project Dodge Ram is also working out great. As of press time, we hadn't yet tested the PSC Motor Sports hydro-assist kit, but we did receive the system and will say it's probably one of the most complete kits on the market, leaving only two hoses for the consumer to source.

Full Hydro DOT Legality?

Someone started a rumor about fully hydraulic steering being illegal for use on the highway. This is not true. We contacted the U.S. Department of Transportation and asked about the rules on hydraulic steering systems. We were told that any rules prohibiting the use of fully hydraulic steering systems in the automotive aftermarket would fall under local laws. We suggest you check with your state's local transportation authorities if you question the legality of hydraulics.

•Pure synthetic oil reduces friction and heat. Heat is the enemy, so it's always a good idea to use synthetic fluid.

•It's very important to bleed all the air from your system before starting your engine and running the pump for the first time. The inside of the pump has several metal-on-metal moving parts that can be damaged if operated without oil.

•All components of a hydraulic steering system should be matched in regards to flow, pressure, and volume. Those who choose to substitute parts of the system with unmatched components will likely encounter undesired results.

•The pulley that drives the power-steering pump should be sized according to the specified rpm limits of the pump. If your engine is capable of overdriving the pump, a larger pulley should be used to slow it down.