While a Mexican standoff typically conjures images of a few angry, gun-wielding hombres stuck in a sticky situation, with no easy means of resolve, our 2004 Grand Cherokee (Project: Grand Score) had its own version of a standoff going on right beneath the driver’s feet. In this particular case, there were no hombre’s pointing Colt SAA revolvers at gringo’s—no, this was a battle of drivetrain wills, with the transfer case, front driveshaft and front differential all duking it out in a battle of rotational supremacy. The effect? A bad vibration, and despite our best efforts of cost-free intervention, neither driveline component was gaining the upper hand.

The cause? After the installation of a 4-inch lift, and subsequent 1.5-inch coil spacers to level things out post bumper and winch installs, the front driveshaft output on the transfer case was now significantly higher than the input of our front differential. The new angle the driveshaft was forced to operate at caused a driveline vibration—a really, really annoying vibration. Sure, we could’ve dealt with the vibes if they were slight (especially on the trail, where they went largely unnoticed) but they weren’t, and we were running the risk of causing long-term collateral damage to both the front differential’s pinion bearings and the transfer case. If you followed along with the Grand Score project, you’ll know our primary goal was to turn this 2004 Grand Cherokee into a jack-of-all-trades, do-most-things daily driver—including happily cruising down the freeway at 70-plus mph. Well, this vibration was putting a serious crimp in our plans.

While we were fairly successful in dialing out most of the vibration by adding negative caster (which raises the pinion of the front differential) via the single adjustable upper control arm of the Iron Rock Offroad long-arm suspension system, once vibe-free, we now had the handling of a 1965 Lincoln Continental with two flat front tires. In fact, the wandering and darting were so scary that we were forced to put some positive caster back in to find a happy medium. The only problem was we now had both sub-par handling and an almost constant driveline vibration. With a full-time all-wheel-drive rig that sees a lot of road time, that’s a double-decker poo sandwich.

In the end you can only modify your rig so much before physics need to be considered. The slope of our transfer case output, matched with where the slope of the front differential’s pinion input was when the caster angle was happy, were too dissimilar for a standard double-cardan ’shaft to operate within its tolerances. Since caster and pinion angles are directly related to each other, there’s no way to adjust one without affecting the other. In case you’re unsure of what caster angle actually is, here’s a quick visual: with the front axle viewed from the side of the vehicle, positive caster has your upper ball joint trailing the lower. When the upper ball joint is leading the lower, you have negative caster. With the ball joints sitting perfectly in line on top of each other vertically, that’s 0 degrees of caster. Generally speaking, most vehicles require some number of single-digit positive caster for proper handling.

If you’re handed the same poo sandwich, you have two options: Option One was to cut the welds around the circumference of the inner knuckles, beat the daylights out of the inner knuckles until they rotate to achieve desired caster angle, and burn them back on with a welder. Option Two was to spring for a Tom Wood’s Multiple Double Cardan CV driveshaft, loaded with Tom’s own Gold Seal universal joints and designed to run happily at dissimilar or compound angles. Option Two is by far the easiest route for those that don’t want to—or lack the proper tools/skills to—complete Option One. Secondly, if you’re not doing the work yourself, you’ll most likely burn through the cost of the Wood’s ’shaft in labor alone to get option one’s surgery completed.

With only four bolts per end to mess with, replacing the ’shaft itself is a super-easy proposition. On the other hand, replacing the required pinion yoke on the front differential is where you could get yourself in trouble, and possibly mess up the preload on the differential’s pinion shaft. Pinion depth on the WJ Dana 30 front axle is set via a crush sleeve instead of steel shims, and since replacing the crush sleeve requires you apply an exorbitant amount of torque to the pinion nut (in the ballpark of 400 lb-ft), we generally try and reuse the original one. The way we’ve successfully replaced the pinion yoke in the past is to (with the original yoke in place) measure both the rotational torque on the pinion (with the frontend in the air, wheels off) using an inch-pound torque wrench and also the amount of torque needed to break the pinion nut free. With that out of the way and the old yoke removed, we installed a new pinion seal, slid the new yoke into place on the pinion shaft, and tightened a new pinion nut (these are considered “one time use”) down to the same torque it took to break the original nut free. Then, we measured the rotation torque again to make sure we were in the same ballpark as before. If it’s not in the ballpark, simply tighten or loosen the pinion nut accordingly.

With the new ’shaft installed and the caster angle set to the positive 6 degrees (what proved to be the happy spot through trial and error), a quick road test told us that we had finally won the battle and had successfully killed any driveline vibration. With smooth sailing all the way to 70 mph, the Tom Wood’s Multiple Double Cardan CV driveshaft represented a relatively easy complete fix to our front driveline conundrum. At a cost of $479 for the ’shaft and $60 for the required pinion yoke, this specialty ’shaft isn’t an inexpensive proposition, but it certainly justified its expense in the results.

Once you’ve pinpointed your front driveline angles as being the source of vibration, followed by hair-pulling and unsuccessful sessions of attempting to strike a balance between proper pinion angle and handling via caster adjustments, your all-wheel-drive rig is probably a good candidate for a Tom Wood’s Multiple Double Cardan CV driveshaft. Our driveline vibration was most noticeable between 35 and 50 mph, which, inconveniently, is right where our Grand spends the meat of its time.

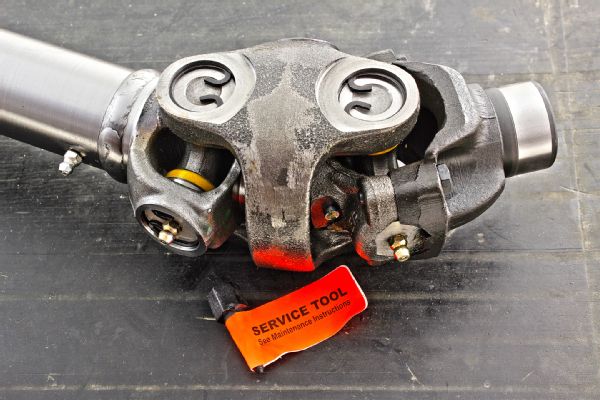

Tom’s magic Multiple Double Cardan shaft (shown here with the required pinion yoke bolted on) is 100 percent brand-new construction, featuring upgraded heavy-wall tubing, a greasable “S” spline slip joint, and the company’s own fully greasable Gold Seal U-Joints. While the optional $25 clear-coated finish, seen here, looks pretty trick and definitely stands out, if you live in an environment that’s a breeding ground for rust, the standard black-painted finish is a wiser choice.

Once you’ve decided to pull the trigger on Wood’s magic ’shaft, the first step will be to measure the overall working length. Tom includes detailed info on his website on how properly measure from point-to-point depending on your yoke style. On a WJ that’s lifted 4 inches or more, you’re factory driveshaft is likely stretched to it outer working limits, so having a ’shaft that’s the correct length will be side bonus to this whole deal.

Since swapping pinion yokes is a prerequisite to installing this ’shaft, you need to make certain the force applied to attach the old yoke is the same as the new one to avoid damaging the front differential’s pinion bearings. Before removing the pinion nut, we measured both the rotational torque it took to turn the pinion yoke and the torque that was required to break the pinion nut free, and we used both as a baseline for installing the new yoke and pinion nut. Don’t forget a new pinion seal and nut while you’re in there.

Other than its slightly longer length to make up for the longer span between transfer case and front differential pinion post-lift, the major difference between the Wood’s Multiple Double Cardan ’shaft and the factory ’shaft is the addition of a second double-cardan joint at the pinion end. Unlike the factory ’shaft, the Multiple Double Cardan ’shaft is effectively able to operate in a working environment involving highly dissimilar or compound angles.

With the caster previously set at positive 3 degrees in order to make the pinion angle happy and reduce vibes, our Grand’s handling became instantly terrible. In fact, it reminded us of an intoxicated fellow trying to make his way to the bar’s bathroom: the wandering and overall clumsiness at speed was comical and butt-puckering, all rolled into one. With the new ’shaft bolted in, and with an inexpensive magnetic angle gauge stuck to the flat surface on the bottom knuckle for measurement, we dialed caster to positive 6 degrees using the adjustment bracket on the Iron Rock Offroad upper control arm.

We love it when something works as advertised, and the actual desired effects are achieved. Such was the case with the Tom Wood’s Multiple Double Cardan CV ’shaft. It absolutely did the trick, and we’re now tooling down the road at highway speeds vibe- and wander-free, just like we did when our WJ was bone-stock. It’s tough to argue with results like that.