On a traditional wheel, the bead on both sides of the tire that contacts the wheel sits on a bead seat just inside the outer diameter flange of the wheel. Air pressure and friction at this interface hold the tire expanded, keeping the tire in place on the wheel and retaining inflation pressure. This all usually works fine for average use, but in the off-road world, we like dropping tire pressure for flex and an increased traction footprint. Hence a beadlock wheel is used to provide a mechanical means of keeping the tire bead in place on the wheel that is independent of inflation pressure. Instead of the tire bead slipping onto a beat seat, it is clamped between a machined surface on the outside of the wheel and a metal ring that is bolted onto the wheel face. This ensures the tire can't be pulled off the wheel bead, regardless of inflation pressure.

Running super low pressures leaves you at risk of pulling a tire off the wheel bead. Another advantage to the addition of beadlocks is that of strengthening the outer wheel lip or flange.

Running super low pressures leaves you at risk of pulling a tire off the wheel bead. Another advantage to the addition of beadlocks is that of strengthening the outer wheel lip or flange.

Beadlocks may be useful in high horsepower applications where you’re running reasonable air pressures. Without them, the tire may tend to want to spin on the wheel. A beadlock can stop that as well as keep the bead firmly clamped.

Beadlocks may be useful in high horsepower applications where you’re running reasonable air pressures. Without them, the tire may tend to want to spin on the wheel. A beadlock can stop that as well as keep the bead firmly clamped.

Back in the day, most people ran 15-inch wheels with tires up to 44 inches in diameter. That creates a tall sidewall height and can result in a lot of leverage at the tire bead. Today, many Jeepers running larger tires have them on 17-inch wheels, which helps some in this aspect, but the issue of tire-bead retention usually returns when running single-digit air pressures.

Beadlock wheels can come ready to rock or can be standard wheels that have been converted. In this case, OMF took a Mickey Thompson wheel and machined off the outer flange. It then welded an inner beadlock ring onto the wheel. Note the serrated lip where the tire bead will now reside.

Beadlock wheels can come ready to rock or can be standard wheels that have been converted. In this case, OMF took a Mickey Thompson wheel and machined off the outer flange. It then welded an inner beadlock ring onto the wheel. Note the serrated lip where the tire bead will now reside.

Here you can see the tire bead sitting in place on the inner ring. The outer ring gets bolted to the inner ring, sandwiching the tire bead. In general, the more beadlock bolts, the better, but 24 or 32 seem to be common numbers on 17-inch wheels.

Here you can see the tire bead sitting in place on the inner ring. The outer ring gets bolted to the inner ring, sandwiching the tire bead. In general, the more beadlock bolts, the better, but 24 or 32 seem to be common numbers on 17-inch wheels.

There are wheels in the aftermarket that were designed from the get-go as beadlock wheels, be they steel or aluminum. Then there are companies such as OMF or Champion that can build you aluminum beadlock wheels from a standard wheel or can turn a set of wheels you already have into beadlock wheels. If you're a proficient welder and want to bust out some sweat equity, you can build your own set of beadlocks from a set of steel wheels. A number of companies offer disc kits to do just that.

Beadlock wheels are certainly more expensive than standard wheels and, all things being equal, will be heavier because of the added outer ring and bolts. Many tire shops won't touch these wheels due to concerns for liability, be it real or perceived. Fortunately, you can mount the tires yourself at home. Balancing may be another matter.

You can mount your own tires at home with beadlock wheels. Simply slide the wheel in the tire from the backside. A spoon or pry bar, along with a little soapy water, will help the tire to slip right on the wheel. Once you unbolt the beadlock ring, getting a tire back off is only half as hard as dismounting from a standard wheel because there's only one standard bead to break.

You can mount your own tires at home with beadlock wheels. Simply slide the wheel in the tire from the backside. A spoon or pry bar, along with a little soapy water, will help the tire to slip right on the wheel. Once you unbolt the beadlock ring, getting a tire back off is only half as hard as dismounting from a standard wheel because there's only one standard bead to break.

Mounting takes some care to do it right. We've seen guys just pull out an air gun and start zipping bolts on. This is generally a poor idea as the ring bolts should be tightened progressively in a criss-cross pattern to prevent undue stress and breakage. Check with the manufacturer for details and bolt torque specs.

As we mentioned before, your most reliable beadlock combination is created when the outer and inner rings touch so you have full mechanical contact. When mounting a beadlock ring, the tire should eventually be clamped fully with the inner and outer rings meeting metal to metal, without exceeding the bolt torque spec.

As we mentioned before, your most reliable beadlock combination is created when the outer and inner rings touch so you have full mechanical contact. When mounting a beadlock ring, the tire should eventually be clamped fully with the inner and outer rings meeting metal to metal, without exceeding the bolt torque spec.

Depending on the thickness of your tire bead, it may be necessary to add thin spacers between the two rings. In this way you can bring the rings together fully without exceeding the torque specs of the bolts. Note that some beadlock manufacturers recommended inflation pressure not exceed certain levels¬.

Depending on the thickness of your tire bead, it may be necessary to add thin spacers between the two rings. In this way you can bring the rings together fully without exceeding the torque specs of the bolts. Note that some beadlock manufacturers recommended inflation pressure not exceed certain levels¬.

You'll also hear a lot of guys complain that beadlock wheels require a lot of maintenance and they have to deal with broken bolts from time to time. Much of this is likely due to not seating the outer ring fully until it is in contact with the inner ring. When you don't have the ring fully seated, the bolts may carry too much of the tire load and the bead rubber in the ring gap squishes around, putting further stress on the bolts. This can lead to loose or broken bolts, hence the complaints. Doing this properly will ensure you'll rarely have a bolt come loose on a quality beadlock.

There are many outer ring options on the market and they vary in size and pattern. When using aluminum rings they often have the thickness available to countersink the bolt heads, further protecting them from scraping on rocks.

There are many outer ring options on the market and they vary in size and pattern. When using aluminum rings they often have the thickness available to countersink the bolt heads, further protecting them from scraping on rocks.

So, do you need beadlocks? If you want greater security of bead retention at low air pressures and can accept the higher cost and weight, then they sound like they're for you. If you don't place as extreme a load on tire sidewalls and want the simplicity of wheels any shop can easily work with, then you may be able to skip beadlocks and spend your dollars elsewhere.

It's possible to build double beadlock wheels like the one shown here, but we see them rarely. There is generally less chance of debeading the inner tire bead than the outer one due to the fact there is usually greater vehicle weight bearing on the outer bead.

It's possible to build double beadlock wheels like the one shown here, but we see them rarely. There is generally less chance of debeading the inner tire bead than the outer one due to the fact there is usually greater vehicle weight bearing on the outer bead.

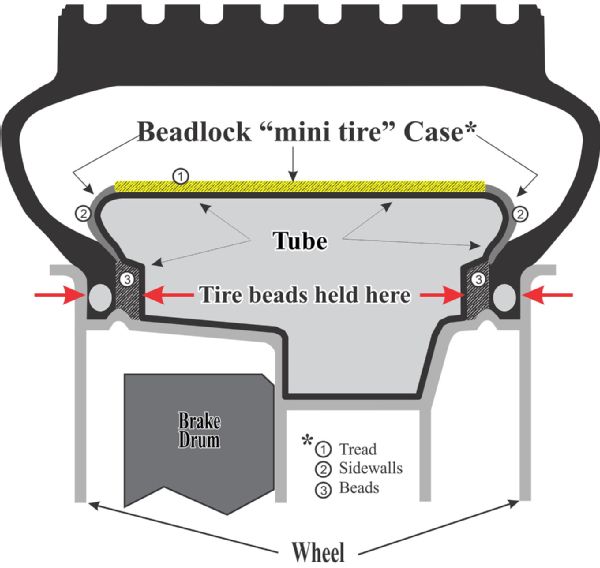

One alternative to the typical metal-ring beadlock is offered by Coyote Enterprises. They manufacture a dual internal pneumatic beadlock that is essentially a tire within a tire. The inner tire is inflated to 50 psi using a second valve stem and is used to retain the outer tire on the wheel. These can be used with a standard wheel.

One alternative to the typical metal-ring beadlock is offered by Coyote Enterprises. They manufacture a dual internal pneumatic beadlock that is essentially a tire within a tire. The inner tire is inflated to 50 psi using a second valve stem and is used to retain the outer tire on the wheel. These can be used with a standard wheel.

Here's a cross-section view of the Coyote pneumatic beadlock. You can see the inner tire that’s inflated and works to apply pressure outward to keep the tire bead seated on the wheel lip. One additional advantage to this design is the inner tire can also serve somewhat as a bumpstop with the 50 psi inflation pressure.

(Photo courtesy of Coyote Enterprises)

Here's a cross-section view of the Coyote pneumatic beadlock. You can see the inner tire that’s inflated and works to apply pressure outward to keep the tire bead seated on the wheel lip. One additional advantage to this design is the inner tire can also serve somewhat as a bumpstop with the 50 psi inflation pressure.

(Photo courtesy of Coyote Enterprises)

A markedly different type of beadlock wheel is the Rock Monster wheel offered by Hutchinson Industries. You may notice these don't have an outer bolt-on ring like most common beadlock wheels. Instead, they use an internal clamping setup secured with the 18 bolts and nuts you see here.

(Photo courtesy of Hutchinson Industries)

A markedly different type of beadlock wheel is the Rock Monster wheel offered by Hutchinson Industries. You may notice these don't have an outer bolt-on ring like most common beadlock wheels. Instead, they use an internal clamping setup secured with the 18 bolts and nuts you see here.

(Photo courtesy of Hutchinson Industries)

Here's an exploded view drawing of a Rock Monster wheel. It actually forms a double-beadlock wheel to secure both the inner and outer tire beads. The two aluminum wheel halves bolt together. Each tire bead is clamped between its respective wheel half and an inner beadlock ring constructed from a rubber compound with aramid fibers for strength.

(Photo courtesy of Hutchinson Industries)

Here's an exploded view drawing of a Rock Monster wheel. It actually forms a double-beadlock wheel to secure both the inner and outer tire beads. The two aluminum wheel halves bolt together. Each tire bead is clamped between its respective wheel half and an inner beadlock ring constructed from a rubber compound with aramid fibers for strength.

(Photo courtesy of Hutchinson Industries)

If you can't quite justify the use of beadlocks but would like to improve the strength of the outer wheel lip on steel wheels, the use of weld-on outer rings can help. These have nothing to do with retaining the tire but simply provide a grind surface and help prevent dents in the outer circumference of the wheel.

If you can't quite justify the use of beadlocks but would like to improve the strength of the outer wheel lip on steel wheels, the use of weld-on outer rings can help. These have nothing to do with retaining the tire but simply provide a grind surface and help prevent dents in the outer circumference of the wheel.