John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

Chevy S-10 Swapping

What is better or easier: To convert an IFS Chevy S-10 4x4 to a solid axle or to convert a two-wheel-drive Chevy S-10 pickup to a solid-axle 4x4? What axle should I use, and what else do I need to complete the conversion?

I like the GM V-6 engines. I want to put a bigger cam into a 2.8L GM V-6 with forged pistons, headers, and the loudest Flowmaster mufflers available. I would trash the TBI and install a carb. Would it be cheaper to put all that into a 4.3L instead? Which engine would I get the best mpg and power from?

Richard Spring

Norfolk, MA

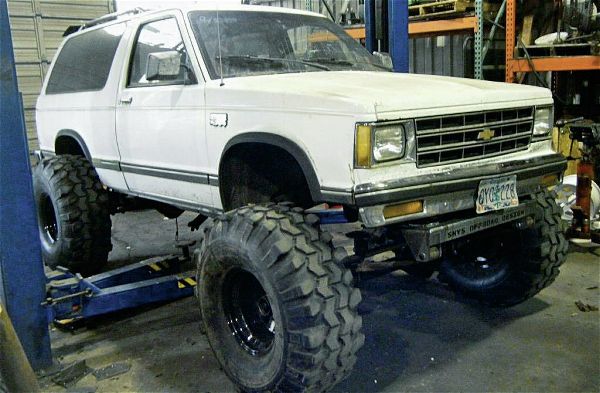

Cutting off the IFS suspension on a Chevy S-10 and replacing it with a solid axle is quite the task. It requires a lot of measuring, as well as fabrication and welding skills. That said, converting a 4x4 Chevy S-10 to a solid axle would be significantly easier. The transfer case and shift linkages are already in place. You also would not need to mess with the existing rear driveshaft.

Starting with a two-wheel-drive truck will require substantially more thought, fabrication, and swapping. You would need to find a 4x4 transmission and transfer case along with all the shift linkages and driveshafts (front and rear), as well as do all the work to get a solid axle and suspension in place up front.

To do the solid axle swap, you could locate the axle and build all of the suspension brackets yourself, or you could save a ton of time and effort and use solid axle swap brackets from Sky’s Off Road Design (sky-manufacturing.com). The Sky’s Off Road Design Chevy S-10 Solid Axle Hanger Kit includes a front hanger/crossmember, rear shackle hangers, front shackles, bushings and sleeves for the shackle hangers, and all of the necessary hardware. The spring hanger/crossmember simplifies the installation of a solid front axle swap by locating the axle and suspension.

The Sky’s Off Road Design kit allows for a 31.5-inch leaf spring length. This is the same as the ’67-’91 solid-axle GM 4x4, Ford, and Jeep Wagoneer. The kit is designed for common 2.5-inch-wide domestic leaf springs such as Rancho (gorancho.com) PN RS44044 for the Jeep Wagoneer. Aftermarket Chevy truck front springs and Jeep YJ Wrangler springs can also be used.

Since the factory S-10 T-case has a driver-side drop, you’ll need to use a front axle with a driver-side differential such as a Dana 44 from an ’80-’91 Wagoneer, Cherokee Chief, or J-truck. The Cherokee Chief and J-truck axles will be the same width as a GM pickup, but the Wagoneer will be about 59 inches between the wheel-mount surfaces. A 1970s Ford, Jeep YJ, XJ, or TJ axle could also be used depending on the width and lug pattern you are looking for.

As for the 2.8L GM V-6, you are better off not putting any money into it. The Chevy Performance HT 3.4L V-6 was designed as a direct replacement for the problematic 60-degree 2.8L. If your S-10 has the 2.8L, simply drive it into the ground and then swap in a 3.4L. All of the 2.8L components will bolt right up. The bummer is it normally sells for between $2,000-$2,500, which doesn’t make its 160hp, 194–lb-ft output that appealing. Unfortunately, the 4.3L GM V-6 is a completely different engine. None of your 2.8L parts interchange. Even the bellhousing bolt pattern is different. The 4.3L has more in common with the GM small-block V-8 than the 2.8L. There is a lot more aftermarket support for the 4.3L than for the 2.8L or 3.4L, but if you’re going through all that hassle to swap a GM 4.3L V-6, why not get a good used LS1?

Overseas TJ

I am a Jeep enthusiast from Scotland in the UK. I have owned three Grand Cherokees, and last year, I bought a ‘98 TJ primarily for off-roading and mud plugging. Rockcrawling does not exist here in the UK. The TJ was modified for off-road work when I bought it. It has a 6-inch Rough Country lift with some Rubicon Express parts. It has a winch, snorkel, and 35-inch tires, and the transfer case and drivetrain have been modified for the lift. I added a set of Bilstein 5100 shocks that I bought from the States.

The previous owner had changed out the Dana 44 rear axle (standard fitting on all UK TJs) for a Dana 35 with disc brakes and a Detroit Locker (yes, I know what you are thinking). The TJ is running 3.73:1 front and rear gear ratios. The front axle is out of a ’99 XJ Cherokee.

I recently broke off two teeth in the rear axle when off-road. I kept hearing a slight clunk, but other than that, the TJ was working well. There was some very thick mud on the trail, and I am sure I heard the locker kicking in when I was belly deep.

I change the fluids each four-wheeling (off-road) session because of all the mud and water I encounter. When I removed the rear diff cover, the two ring gear teeth were in the gloop/oil that came out.

To get to the point, I am replacing the rear axle with a used Dana 44. It has a 3.73 gears. Are the 3.73s good for what I do with the TJ? It is only used on-road to drive to and from off-road sites. The Jeep is not a daily driver. If I go a long distance, I put the Jeep on a trailer.

My wheeling is 95 percent all-terrains with plenty of mud, climbs, descents, and so on. Fuel consumption and highway performance are not important to me.

Mike Worrall

Via email

Editor Hazel replies:

Greetings, Michael! I Love hearing from Jeepers outside of the U.S. Thanks for writing.

For starters, allow me to clear up one common misconception about a Detroit Locker (eaton.com). They engage (lock) under power and stay locked as long as power is being applied. They only disengage when no power is being applied, and there’s a torque bias to overcome the springs inside the unit. By torque bias, in this case, I mean one tire travelling faster than the other. So in other words, the locker shouldn’t disengage unless you’re off the throttle and the vehicle is turning while moving. It doesn’t have to be a big turn – just enough to make one tire spin faster than the other. However, the key is it will only disengage when you’re off the throttle, not while you’re on the power.

All that understood, when you say you were “hearing the locker kicking in while you were belly deep in mud,” it’s doubtful the noise you heard was the locker engaging and disengaging. More likely what you were hearing was the teeth that broke off your ring gear rattling around inside the axle. Since you’re swapping to a Dana 44, it’s really a moot point, but I just figured I’d take the opportunity to address that.

As for the gear ratios, I know you said mileage and on-road drivability aren’t your primary concern. Still, my recommendation would really come down to whether your Jeep has the three-speed automatic transmission used in ’98 or the five-speed manual (AX15) with Overdrive. Ideally, for a 4.0L-powered Wrangler running 35s, I’d recommend 4.56 gears for the best off-road performance. For myself, I’ve run gearing as deep as 4.88 on a daily driven 4.0L/four-speed auto with Overdrive-equipped Cherokee with 33s. The road speed doesn’t suffer as long as you have the Overdrive, and the 4.0L will happily spin near 3,000 rpm above 75 mph on the highway all day long. So your engine speed would be around 3,100 rpm at 65 mph. If that’s acceptable, then the 4.56s may be for you.

In a nutshell, I’d recommend 4.56s, but keep in mind it’ll be rather expensive to regear both the front and rear axles. It’s not just the parts, but the labor involved. Find a good shop in your area that’s well versed in setting up gears. You don’t want to destroy a brand-new gearset because of an improper installation. You’ll be able to reuse your front carrier on the high-pinion Dana 30, so that saves you a little money. On the rear, if the axle you’re starting with already has 3.73-numerically lower gears, then you’ll need a new carrier for 3.92-up gears. This probably isn’t an issue considering you’ll want to put another locker in the rear. If you can afford it, I’ve had really good luck with the Eaton ELockers, but if you’re a Detroit fan, go for what you like. You could also consider a full spool for the rear. They act like a Detroit Locker but without all the drawbacks associated with the Detroit’s locking and unlocking. One caveat: Never put a spool in the front axle of a recreational 4x4.

Check out this website for a little more info on the carrier splits and prices: drivetrainspecialists.com/categories/dana/dana-44/.

How Big?

What size spring-under lift should I buy for my ’90 YJ? I want to run 35x12.50 tires.

David W. Green

Via facebook.com/JohnCappa4x4

There are many different ways to fit 35-inch tires under your Jeep YJ. The fact of the matter is that the YJ has somewhat smallish wheelwells, so going with a big lift kit alone really isn’t all that practical of a solution. You’ll need a 6 to 8-inch lift to clear the tires cleanly. However, if you are willing to install a 4-inch suspension lift, a 1 to 2-inch body lift, and trim the fenders a bit, you can fit the 35-inch tires you want. Other options include a small lift and massively trimmed fenders. You can also install aftermarket fender flares with larger wheel openings. I’d recommend using the smallest lift kit possible and fit the tires to the wheelwells with trimming and aftermarket flares or fenders. This will help keep the center of gravity low and keep the steering and driveline angles in check. Also, if you plan to use the Jeep off-road, I’d highly recommend swapping out the factory Dana 35 rear axle. It’s a time bomb waiting to go off rolling on 35-inch tires.

Vacuum Axle

I have a ’97 Isuzu Rodeo, and I have put a used rearend under it from a junkyard. The rear end is a Dana 44 with a vacuum line hookup. My question is, if I buy a replacement cover for the rearend, does it have to have a vacuum line hookup on it? I noticed most of the covers I find do not have a vacuum line hookup. Thank you in advance for your help!

Chris Beasley

Via fourwheeler.com forums

There are no vacuum lines on the Isuzu Dana 44 rear axle. There should be a rubber hydraulic line for the brakes, an ABS wire that connects to a sensor bolted to the top of the cast portion of the housing, and a rubber breather hose attached to a fitting that is screwed into the top of the differential cover. This breather is needed to let heated air escape the housing. It also lets air to return to the inside of the housing as the assembly cools.

In case you were wondering, sealing the axle completely with a new cover and no breather would cause the heated air pressure to build up inside the axle until oil is forced past the seals. You can drill and tap the new cover for a breather fitting in the same location as stock, or you can move the breather to the axletube by drilling and tapping a hole there. Be sure to remove any metal chips from the inside of the housing after drilling and tapping your new breather fitting. If you frequent deep water crossings, attach a hose to your axle and run the line as high up on the chassis as possible. This prevents water from being sucked into the hot axle assembly when quenched during the water crossing.

JK Axle Axing

What do you think of Dynatrac ProRock 44s wheeling 37 to 40-inch tires under a Jeep Wrangler JK Unlimited?

Chris Garland

Via facebook.com/JohnCappa4x4

The Dynatrac (dynatrac.com) ProRock 44 axles are a great upgrade over the factory ’07-to-present Jeep Wrangler and Wrangler Unlimited axlehousings. When bigger tires are added to the stock Wrangler housings, they can bend. We have even seen factory JK front housings literally snap in half under normal use. And while the next-generation Dana 44 gears, axleshafts, and other internals are very durable, a 37 to 40-inch tire is just too much for the entire Dana 44 assembly in most cases.

The maximum tire diameter I’d be comfortable running on a ProRock 44 is a 35 to 36-inch tire. Ultimately, it depends on how you plan to use the vehicle. If your Jeep is a street-only rig, I think you could make that combination survive. However, if you plan to use the Jeep off-road, especially in the rocks with a front and rear locker combined with a Rubicon T-case, you really need to step up into ProRock 60 axles. The ProRock 60 can better handle the torque load and stresses caused by the weight of the Jeep, large diameter tires, and low gearing.

Where To Write

Have a 4x4 tech question you want answered in Techline, drop an email to editor@fourwheeler.com or head on over to our forums at fourwheeler.com. All letters become the property of Four Wheeler, and we reserve the right to edit them for length, accuracy, and clarity. Due to the volume of mail, electronic and otherwise, we cannot respond to every reader, but we do read everything.