Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

If you’ve ever purchased a wheel strictly off of looks alone, you are not alone. We’re not saying it’s a good thing, but we completely understand. The right wheel and tire package can make all the difference. For those looking simply to give their Jeep a new look, the difference between cast or forged aluminum wheels isn’t going to be a deal breaker. It’s when you get to the more serious side of the off-road hobby that choosing the right wheel can become critical.

Bead retention is one area that we focus on more than almost any other. Since a traditional wheel uses air pressure to keep the tire mounted to the wheel, at low air pressure, it can become dislodged from the wheel. This is often why you see us, as well as other wheeling enthusiasts, opting for beadlock wheels. A beadlock wheel is one that is constructed to “lock” the bead of the tire onto the wheel itself. However, it’s not without its own drawbacks as well.

Understanding your options and how they work will ultimately lead you to the right wheel for your Jeep. Whether the rim is steel, aluminum, beadlock, or even if it’s DOT-compliant are all factors to consider. Add in backspacing, valve stem placement, and design, and wheel buying just became more complex. We’ve put together an assortment of some of the most popular and latest wheel construction offerings for the off-road hobby. While looks may still be a huge deciding factor, having the right information about what you’re actually getting should help ease the investment.

Steel

When we first started in the wheeling hobby, steel wheels were our go-to. The relatively low cost and rugged strength of the wheel make them a staple in the off-road hobby. The biggest downside to a steel wheel is weight. Even in modest 15-inch wheel size, a steel wheel weighs significantly more than a comparable aluminum wheel. This increase weight translates to decreased performance and fuel economy.

The plus side to the budget-friendly wheel is they can often take years of abuse. Depending on the severity of the damage, it’s even possible to fix a damaged steel wheel on the trail, not a feat easily accomplished with an aluminum counterpart. A typical non-beadlock steel wheel will allow you to run the same low-air pressure range as a non-beadlock aluminum wheel, so there’s no advantage in regards to bead retention. When it comes to strength and durability, it’s hard to beat a steel wheel for the cost.

Steel

Steel

Aluminum

Your average aftermarket aluminum wheel is typically cast. Sadly, it’s probably not made in the USA, but the quality is much higher these days than in years past. While not as strong as a forged aluminum wheel, a cast-aluminum wheel is usually great for the daily driven wheeler. Forged wheels are mostly used for racing applications and rigs that require extremely high load ratings. There is actually a school of thought among some off-road racers that prefer cast over forged. Their reason is simple, a broken wheel is easier to replace on the fly over a broken axle or suspension member. If the wheel doesn’t break, something else will need to absorb the impact.

For most wheelers, a cast-aluminum wheel is plenty. Since the cost of aluminum wheels has come down over the years, the argument of cost over steel wheels isn’t as valid. The lighter wheel will help with the rolling resistance, which will equates to a lesser hit to the Jeep’s performance and fuel economy over a steel wheel. A known issue of some lower-end cast-aluminum wheels is that they are might crack when making an extremely hard impact with terra firma. Unlike a steel wheel, which can often be easily repaired, a broken cast wheel is usually done. As we mentioned, bead retention is comparable to a standard non-beadlock steel wheel, but more aftermarket companies choose cast aluminum as its base for beadlock wheels.

Aluminum

Aluminum

16.5 Wheels

With the exception of the H1 double-beadlock wheel, a 16.5-inch wheel should be avoided completely. This is because of the unique shape of the 16.5-inch wheel. Specifically, the 16.5 lacks what’s known as a safety bead around the edge of the wheel. This is the ridge that helps keep the tire’s bead in place. Where you can dabble in the 10-12 psi range with a regular non-beadlock wheel doing so with a 16.5 is almost certain to result in a tire dislodging from the rim. The fact that tires are more difficult to find for the 16.5 is making them more obsolete as well.

16.5 Wheels

16.5 Wheels

Sizing Up

Picking the right wheel and tire package is a balancing act. You want a healthy amount of sidewall as it will allow the tire to grip the terrain better and work as a secondary suspension for your 4x4. Too little sidewall and the tire can’t perform as well off-road. Too much, and the tire can be unstable in off-camber situations.

For years, the 15-inch diameter wheel was the standard. In many cases, it still is. The light-truck market strongly supports the 15-inch wheel, so we don’t see it going anywhere, anytime soon. With that said, the trend is definitely moving towards larger wheels. If we had to pick the most popular size in the Jeep/off-road community, without question it’s currently the 17-inch wheel. Sure, 17 inches used to seem like a large wheel, but 35s used to be considered monstrous as well. The larger diameter wheel makes it easier for both the OE and aftermarket sectors to fit larger brakes, better steering, and more durable axle components.

Sizing Up

Sizing Up

Almost A Lock

Known for its legendary line of aggressive off-road tires, Interco Tire saw an opportunity to capture a part of the market that has been ignored. With its Birddog line of wheels, the company has designed a non-beadlock wheel that’s intended to allow you to safely run low air pressure off-road. This is accomplished by using what the company describes as an air retention rib. The rib works by compressing the foot of the bead just forward of the bead bundle in a small area.

The idea is for the elasticity of the bead to maintain contact with the wheel when deflected in either direction at low air pressures. The wheel has other off-road-oriented cues, such as dual valve stems, a tapered angle for self-cleaning, and is comprised of cast aluminum for weight savings. Currently, the Birddog is offered in 15,16, and 17-inch wheel sizes, with an assortment of bolt patterns and backspacing options. We wouldn’t consider this a beadlock replacement, but it’s a great alternative for someone looking for a DOT-compliant wheel that offers enhanced bead retention.

PhotosView SlideshowB.A.D. Wheels

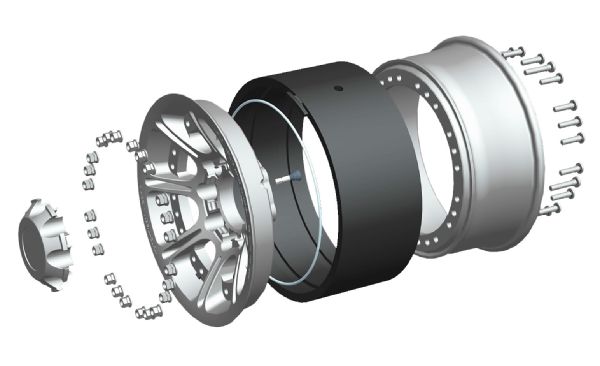

Most beadlock wheels require constant attention and are not DOT-compliant. For this reason, many daily driven 4x4s will often have a separate set of on- and off-road tires and wheels. A few year ago, Bead Assist Device Wheels (AKA B.A.D. Wheels), launched its DOT-compliant Eklipse 17 beadlock. The wheel works by using three internal bead clamps, which lock down the outer bead of the tire between the clamps and wheel.

Once you have the nuts locked down, you use locking pins to make sure the nuts can’t back off. This makes the beadlock wheel essentially maintenance free. The cast-aluminum wheel is around 50 pounds when affixed with a 1⁄2-inch rock ring, so it isn’t super light, but you’re getting a lot of strength . Currently, the wheel is only offered in a 17, but it does have multiple wheel bolt patterns.

B.A.D. Wheels

B.A.D. Wheels

Outside Clamping Beadlocks

The most common beadlock offered in the aftermarket is the type that uses an external clamping ring. Companies such as Trail Ready and ATX are both well-known for its heavy-duty beadlock offerings. Typically comprised of cast aluminum (though some forged wheels are available), the wheel uses an external ring to actually sandwich the bead between it and the body of the wheel. The external ring design makes them field serviceable and easy to assemble in your home garage.

In terms of weight, it will vary from company to company. The big downside to this type of beadlock is that they require constant attention and they are not DOT-compliant (hence the off-road only moniker that most come stamped with). While rare, you can still have an inner bead break free on this style of beadlock.

PhotosView SlideshowDual Beadlock

If you want to make certain that both beads are locked firmly to the wheel, a dual beadlock is what you are looking for. Be prepared to spend handsomely for it. Companies such as Hutchinson Industries offer its Rock Monster DOT-compliant dual-beadlock wheels that use an inner ring to sandwich both sides of the tires bead in place. Like an outside clamping beadlock, this style of wheel is field serviceable and can be mounted from home. The multi-piece cast aluminum Rock Monster is offered in an assortment of sizes and bolt patterns. If you’re looking for legal and double-beadlock, it’s one of your only options. Due to the design, these wheels are usually pretty heavy.

Dual Beadlock

Dual Beadlock

Weight Rating

Just as important as picking the correct load range rating for your tire is getting a wheel that can support said rating. You can usually find the wheel’s rating on the manufacturer’s website or stamped on the inside of the wheel.

Weight Rating

Weight Rating

Backspacing

Backspacing is measured from the wheel’s mounting surface to the outer lip on the backside of the wheel. The lower the backspacing number, the farther the wheel will set outside of the vehicle. Factory wheels tend to have higher backspacing numbers to keep the tires tucked neatly inside of the wheelwell. For aftermarket wheels, 3.5 to 4.75 inches of backspacing is very common. We tend to like our wheels with 3.5 to 3.75 inches of backspacing as it works best to clear suspension and steering components. One of the downsides of a numerically low backspacing number is the added leverage and drag that it places on your frontend components. Items such as wheel bearings and ball joints will often wear more rapidly, but in some applications, upgrades are available to compensate. You may also see offset listed. Offset is the distance from the centerline of the wheel to the wheel mounting surface. Offset is considered positive if it’s towards the outside of the wheel and negative when towards the back side of the wheel.

Backspacing

Backspacing

8 vs. 10

Wheel width options lessen as the wheel size increases, but the age old debate of an 8-inch-wide wheel versus a 10-inch-wide wheel is still active today. A 15x8 versus a 15x10 is a great example. While two inches might not seem like much, it is enough to matter off-road. For a comparison take, say you have a 35x12.50 tire mounted on one of each wheel. The contact patch of the 10-inch-wheel has the potential to be greater than that of the 8-inch-wide wheel since the wheel separates the bead bases more on the 10. Off-road, we’ve found that the wider 10-inch wheel is more apt to lose a bead at low air pressure over an 8-inch. This can be tire dependent, but for the most part, we prefer the safety of a 8 over a 10 when frequent low-pressure wheeling is prevalent.

Valve Stems

Valve stem damage is one of the most common causes for flats off-road. On a stock wheel, the valve stem can stick out past the lip of wheel, becoming one of the first items to make contact with any obstacle in its way. For this reason, we suggest finding a wheel that has the valve stem either protected or recessed further inside of the wheel. Dual valve stems are showing up more these days as it allows for faster and more precise airing down. More stems can also be more problems if you’re not careful off-road.

Valve Stems

Valve Stems

To Lock or Not?

Purchasing a new wheel set is no small investment. When you add the option of the wheel being a beadlock, you can often double that cost. No matter where you go off-road, lowering the air pressure in your tires will improve both the ride quality and performance of your Jeep. For more extreme rockcrawling and trail riding, beadlocks are as close to a necessity as differential lockers. With so many tire companies moving to thicker sidewalls and higher load range ratings, the beadlock wheel is becoming more of a necessity than in previous years. However, you can push your basic non-beadlock wheel safely into the 10-12 psi range without much worry, which makes a tremendous difference as well. For our money, beadlocks are worth the investment if you really believe you can take full advantage of them.

DOT Compliant

We’ve mentioned tires being DOT (Department of Transportation) compliant a few times in this article and want to shed a little light on this. When a wheel is not DOT-compliant, it doesn’t mean that it is unsafe or doesn’t adhere to DOT wheel-construction standards. The issue is that there are currently no specific regulations or test requirements in place for outer-ring clamping beadlock wheels. For this reason, most manufacturers offer outer-ring clamping beadlocks labeled for competition and/or off-highway use only.

Since the majority of beadlocks use bolts to sandwich the tire’s bead between an outer locking-ring and the wheel, you run the risk of the bolts working loose over time. If continued to go unchecked, the results can a damaged wheel, tire, or a real catastrophe. Just as you should periodically check your rig’s lug nuts, beadlock wheels require routine maintenance. Each wheel manufacturer has specific torque requirements and suggested service intervals. We like to check ours after every wheeling trip and oil change. Some manufacturers even suggest swapping in new bolts each year. The bottom line: If you are running beadlocks, you need to inspect them frequently to make certain they are safe for you and others on- and off-road.