The rapid rise of fossil fuel costs, such as crude oil, coupled with great demand for them, has forced consumers in the United States and around the world to consider the potential of alternative fuel usage.

Several alternatives have arisen over the past few years, but one alternative fuel is clearly a better and less expensive choice than all of the others. Cure your oil addiction by converting your car from a gas guzzler to a hybrid hottie.

Measure the current operating temperature of your vehicle using a cylinder head temperature (CHT) gauge). The CHT gauge is used to make sure your car is not overheating. An Exhaust Gas Temperature (EGT) gauge can also be used for this purpose. Both of these gauges are designed to fit right under your spark plug.

Install the gauge by locating the cylinder head spark plug of your engine.

Remove that spark plug, insert the gauge, and replace the spark plug.

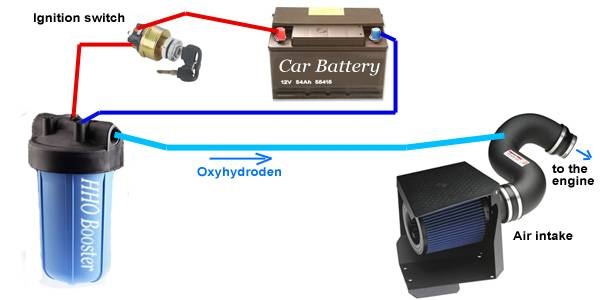

Build a circuit control using the diagram shown here.

Construct the circuit with a transistor designed to work on anywhere from one to five amps.

Use the control circuit with the Reaction Chamber (instructions below) override the controls that are currently on your vehicle to facilitate the process of having the car convert water to fuel.

Construct the reaction chamber to test with the controller you built in Step 2 above. The reaction chamber is a component shaped like a cylinder, and made from PVC pipe. The reaction chamber is where the actual fuel conversion process takes place.

Take the 4" PVC pipe that has a fitting for a screw cap on one end and that has a standard cap on the other. Put the electrodes into the threaded end and fill the chamber with water to about 3/4 full. The electrodes should touch the water, but not be fully submerged in it. The power from the control circuit will convert the water from its liquid state into its gaseous state.

Make sure that the wires internal to the chamber are stainless steel and are protected by some type of coating (to prevent rusting). Wires external to the chamber should be insulated.

Complete the installation of the chamber, tank, controller and fittings.

Run your engine so that you can adjust the controller, if needed.

Install stainless valves.

Coat the pistons and cylinders with ceramic surface treatment.

Cover the exhaust with a ceramic surface treatment.