The Combo

As detailed in our Aug. 2013 “HOT ROD to the Rescue,” Chris William’s 2008 SRT Challenger couldn’t keep a drivebelt on its 1,000hp, blown, 426ci, late-model Hemi stroker. After many trials and tribulations, Norm Brandes’ Westech Automotive in Silver Lake, Wisconsin, perfected the front-drive system, only to have the power-steering pump go Dixie when it couldn’t withstand the newly stable eight-rib serpentine drivebelt’s tremendous torque. We fixed that, too. Williams was definitely a happy camper when he left Westech, with everything at last seemingly OK. But several months after the car drove away, it limped back into Westech. The Challenger’s independent rear suspension (IRS) was making noise.

When not at his day-job keeping quarterbacks alive, St. Louis Rams offensive lineman Chris Williams lunches drivetrain parts for a hobby.

When not at his day-job keeping quarterbacks alive, St. Louis Rams offensive lineman Chris Williams lunches drivetrain parts for a hobby.

The Problem

It’s thought the Challenger’s burnouts caused wheelhop that the original Mercedes IRS couldn’t withstand. The lowered car also had rear alignment problems: Note how the tops of the massive tires lean-in, reducing their contact patch.

It’s thought the Challenger’s burnouts caused wheelhop that the original Mercedes IRS couldn’t withstand. The lowered car also had rear alignment problems: Note how the tops of the massive tires lean-in, reducing their contact patch.

“After Norm fixed the belt, I was able to put about 2,000 miles on the car,” reports a chagrined Williams. Williams, a St. Louis Rams offensive lineman, only knows one way to drive: pedal to the metal. His favorite stunt: 40–80-mph burnouts. Cruising down the interstate, Williams rolls into the throttle and fries the tires. That’s when the drivetrain began making noise.

Inspecting the car in-shop, Brandes shifted the NAG1 five-speed automatic overdrive from Forward to Reverse. During the gear transition, at first it sounded like a set of spiders going away. But the problem would turn out to be more complex than that.

The Diagnosis

Williams’ car already had a modified rear suspension, the strongest RCV halfshafts and CV joints available, and a tough Quaife limited-slip diff with 35-spline drive axles (stock is 31) in the 3.07:1-geared Mercedes 215mm (8.46-inch) rearend. That’s kinda weak compared to the famed muscle-car solid axles of yore, but on the other hand, Williams’ abuse was from a 40-mph roll, during which the tires seemingly weren’t hooking up. According to traditional bench-racing theory, what kills a rearend is the instant shock-loading when the tires firmly grab. Yeah, but on the other, other hand, we’re talking an estimated 1,000 flywheel lb-ft of torque here.

What at first was thought to be noise from bad spider gears in the diff was actually excessive play between the halfshafts’ caged bearings inside the CV joint “bells.” “We could rotate the stub axles in the centersection 1⁄16 of a turn before the CV joints engaged,” explained Brandes. RCV, the CV jointed halfshafts’ manufacturer, failure analysis later confirmed the CV joint was operating pretty close to design spec, but that high-speed tire spin was hammering the joint.

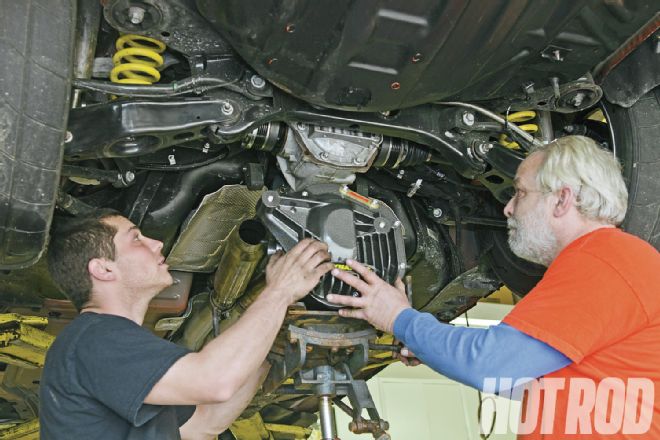

Farewell Mercedes, hello Dana: Westech’s Corey Wilcox (left) and Jim Daley eyeball what it’s going to take to install the Dynatrac Pro60-IRS.

Farewell Mercedes, hello Dana: Westech’s Corey Wilcox (left) and Jim Daley eyeball what it’s going to take to install the Dynatrac Pro60-IRS.

“It used to be that a spinning tire was a happy tire. But with tough aerodynamics and lots of downforce, that’s not necessarily true anymore.”

— Norm Brandes, Westech Automotive

The same pounding was also affecting the rearend housing’s internal guts. When inspected, the limited-slip differential, side gears, and ring-and-pinon had internal slop and wear. “Everything in the rearend was loose,” explains Brandes. It wouldn’t be long before it failed, too.

Remember, engine torque gets multiplied as it passes through the drivetrain. Even assuming the trans was in Fourth (1:1), and discounting any additional torque converter multiplication through the drivetrain, a 3.07:1 ring-and-pinion will multiply the torque by just over three times. So if there’s 1,000 lb-ft of torque at the flywheel, that would be 3,000 lb-ft through the shafts out of the rearend!

That’s a tough nut to crack, but wait, it gets worse: If the NAG1 five-speed automatic was in its 3.59:1 First gear, there’s a potential 10,000-plus lb-ft to deal with (1,000 × 3.59 × 3.07). And this still doesn’t include additional stress from the oscillating-pendulum effect induced by the rapid wheel-hop on the halfshafts and CV joints. Gulp!

Brandes fought back with a two-pronged resolution: a stronger IRS on the one hand; rear suspension adjustments on the other. The suspension adjustments were needed because the existing RCV-made 35-spline halfshafts and heavy-duty CV joints were already the stoutest available parts that had any chance of fitting the car.

The Fix: IRS Upgrade

Dana 60 to the rescue, courtesy of Dynatrac. Its 9¾-inch ring-gear is quite a step up from the car’s stock 8.46-inch Mercedes rear.

Dana 60 to the rescue, courtesy of Dynatrac. Its 9¾-inch ring-gear is quite a step up from the car’s stock 8.46-inch Mercedes rear.

Dealing with the basic rearend first, there are several choices in aftermarket IRS upgrades. Conversions are available to install a Ford 8.8-inch, a Ford 9-inch, or a Dana 60 9¾-inch centersection. Brandes chose Dynatrac’s Pro60-IRS Dana 60-based conversion. The Dana has the strongest ring-and-pinion, it fits easier within the Challenger’s existing envelope (the Ford 9-inch, Brandes says, requires redoing the whole rearend frame-cradle), and “it keeps the heritage,” as many old-school Mopar muscle cars and even some Jeeps and Dodge trucks today utilize the beefy Dana.

The new, black-painted Dana 60 housing is slightly longer, taller, and wider than the original-aluminum Mercedes housing it replaces.

The new, black-painted Dana 60 housing is slightly longer, taller, and wider than the original-aluminum Mercedes housing it replaces.

The Pro60 includes Dana 3.54:1 gears, a rugged Eaton Detroit Truetrac limited-slip diff, RCV 35-spline halfshafts and CV joints, and wheel bearings. Dynatrac optionally offers just about any traction aid, including a spool, Detroit Locker, or ARB Air-Locker, but Brandes considers the torque-biasing, helical-gear Truetrac “the best diff for this application because it’s strong yet not unduly harsh.”

You can normally buy the rearend housing fully assembled through Dynatrac—along with the necessary external halfshafts, hubs, CV joints, and brackets. The parts were donated for the Rescue in this instance, so Brandes got the diff directly from Eaton (PN 915A387 for 35-spline axles and 4.10:1-and-numerically-lower gear ratios, $649.97 if purchased separately through Summit Racing). Meanwhile, RCV reworked and rebuilt the Challenger’s existing halfshafts and CV joints. Everything else—including the bare Dana 60 centersection along with other unassembled internal parts such as the ring-and-pinion, bearings, and stub axleshafts—came from Dynatrac.

Still, Brandes says it fits better than a 9-inch-Ford–based centersection.

Still, Brandes says it fits better than a 9-inch-Ford–based centersection.

Dynatrac sells its Pro60-IRS conversion for ’08-and-newer LC and LX Mopars either complete, bare with just the 35-spline stub axles (for DYI guys), or virtually any state in between. The Dynatrac nodular-iron housing uses rugged Dana 60 internals, including a choice of 3.54–7.17:1 gear-ratios (3.54:1 is used here). RCV chrome-moly halfshafts with beefed-up CV joints are said to be the strongest available.

Dynatrac sells its Pro60-IRS conversion for ’08-and-newer LC and LX Mopars either complete, bare with just the 35-spline stub axles (for DYI guys), or virtually any state in between. The Dynatrac nodular-iron housing uses rugged Dana 60 internals, including a choice of 3.54–7.17:1 gear-ratios (3.54:1 is used here). RCV chrome-moly halfshafts with beefed-up CV joints are said to be the strongest available.

Getting the center-housing assembly to fit the existing cradle required some clearancing mods, as shown in the photos. Accommodating the longer and wider Pro60-IRS housing also mandates a shorter main driveshaft and shorter halfshafts.

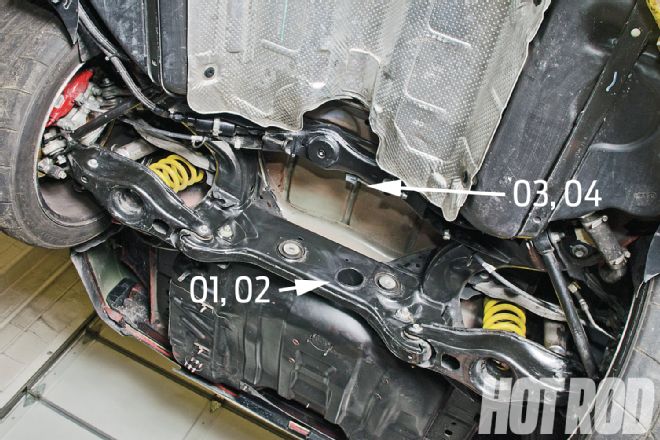

To get the Pro60-IRS to fit in the car, the flanged through-hole’s lip on the IRS’s rear cradle crossover was trimmed (details, photos 01–02). On the forward horizontal crossover, the double-walled member was messaged near the forward housing mount (photos 03–04).

To get the Pro60-IRS to fit in the car, the flanged through-hole’s lip on the IRS’s rear cradle crossover was trimmed (details, photos 01–02). On the forward horizontal crossover, the double-walled member was messaged near the forward housing mount (photos 03–04).

To gain the remaining needed front clearance, Westech sonic-checked the housing, then ground off about 0.100 inch of material from it in the area shown (arrows).

To gain the remaining needed front clearance, Westech sonic-checked the housing, then ground off about 0.100 inch of material from it in the area shown (arrows).

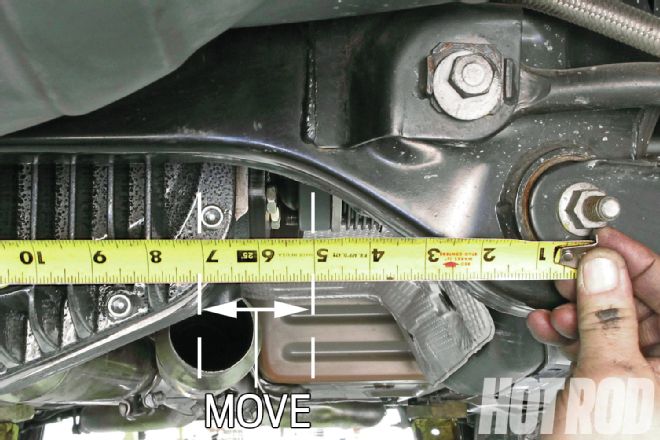

The lower control arm attaching bolt (arrow) was used as a datum point to determine how much shorter the halfshafts needed to be with the wider Dana housing. The new Pro60-IRS housing and stub-axles are 2¼ inches wider overall, so the new RCV ’shafts were shortened 11⁄8 inches per side.

The lower control arm attaching bolt (arrow) was used as a datum point to determine how much shorter the halfshafts needed to be with the wider Dana housing. The new Pro60-IRS housing and stub-axles are 2¼ inches wider overall, so the new RCV ’shafts were shortened 11⁄8 inches per side.

The larger housing hit the exhaust near the CV joints, so it was moved outboard 2 inches. Brandes explains, “We used Dynomax’s cat-back H-pipe and offset muffler, then sectioned and relocated the car’s existing rear SLP tailpipe.” (The SLP system is no longer made.) Here, the lower control-arm bolt (A) is again used as a measurement datum point.

The larger housing hit the exhaust near the CV joints, so it was moved outboard 2 inches. Brandes explains, “We used Dynomax’s cat-back H-pipe and offset muffler, then sectioned and relocated the car’s existing rear SLP tailpipe.” (The SLP system is no longer made.) Here, the lower control-arm bolt (A) is again used as a measurement datum point.

The Fix: Rear Suspension

Stiffening up the rear suspension is one possible solution to fighting high-speed oscillation, but the SRT8 already comes stock with urethane bushings and heavy-duty springs. Brandes ultimately decided that the most expedient fix was to increase the tire contact patch on the heavily lowered car. A stock SRT8 Challenger already sits 1-inch lower than other stock Challengers, but as-received,Williams’ car had been lowered another 2 inches beyond even a factory SRT8. The extreme lowering caused the IRS to have negative camber—the tire tops leaned in toward each other, canting the tires at an angle and reducing their contact patch. Brandes realigned the IRS to yield as close to zero camber as possible within the constraints of the car’s super-low ride height (see chart). The shocks were also adjusted to a firmer setting.

The existing stock rear suspension bolts up. However, to reduce the transient oscillation problems Westech tweaked the rear alignment to increase the tire contact patch and improve stability by reducing negative camber and toe-in. As a final anti-wheelhop measure, the car’s double-adjustable shock absorbers were adjusted about two clicks stiffer on both their jounce and rebound settings.

The existing stock rear suspension bolts up. However, to reduce the transient oscillation problems Westech tweaked the rear alignment to increase the tire contact patch and improve stability by reducing negative camber and toe-in. As a final anti-wheelhop measure, the car’s double-adjustable shock absorbers were adjusted about two clicks stiffer on both their jounce and rebound settings.

The Fix: ECU Tune-up

The new rear-gear ratio required recalibrating the ECU and electronic speedometer. The car’s original tune also caused some minor driveability problems. Killing two birds with one stone, Brandes recalibrated the entire computer from scratch using a DiabloSport inTune handheld tuner licensed to the car.

As a final step, Westech used a hand-held DiabloSport inTune programmer to recalibrate the Challenger’s factory ECU and electronic speedo for the new rear-gear ratio. At the same time, the overall engine map was tweaked for improved performance. “We improved the driveability and seat-of-the-pants feel,” Brandes says.

As a final step, Westech used a hand-held DiabloSport inTune programmer to recalibrate the Challenger’s factory ECU and electronic speedo for the new rear-gear ratio. At the same time, the overall engine map was tweaked for improved performance. “We improved the driveability and seat-of-the-pants feel,” Brandes says.

Results

Originally designed for big trucks, the robust Dana 60 is much stronger than the factory rearend. With the rest of the IRS beefed to the extent possible within the confines of the basic suspension design and clearance envelope, the alignment improved, and the shocks properly adjusted, the IRS is currently still kicking several months down the road. Keep your fingers crossed—Williams still hasn’t hit the NOS button.

Lessons Learned

The entire driveline must be able to handle the stresses placed upon it. Just because the tires seem to be spinning—not planting—doesn’t mean a marginal rearend design will live, especially on a vehicle with double the factory horsepower.

With Dana 60 gears and subtle rear suspension tweaks, tire smoking is no longer hazardous to the Challenger’s health.

With Dana 60 gears and subtle rear suspension tweaks, tire smoking is no longer hazardous to the Challenger’s health.

Rear Alignment

Setting Before After Left Right Left Right Camber –2.0 –2.2 –1.9 –2.1 Toe –0.12 –0.06 0.23 0.21 Total Toe –0.18 0.44 Thrust Angle –0.03 0.01

All values in degrees.

Parts and Prices

Includes major parts and machining required to fix the problem. Does not include labor, shipping, miscellaneous small shop parts, or sales taxes. Priced 07/28/13 and subject to change.

Brand Part Description Part No. Price Source Cost DiabloSport ECU Programmer, inTune hand-held device I1000 Summit $389.00 Don’s Auto Parts Driveshaft, shorten and install conventional 1350-series U-joint Custom Westech $225.00 Dynatrac Rearend Conversion, Pro60-IRS¹ CH60-4141-A Dynatrac $4,169.77 Dynomax Exhaust System, dual 3" cat-back stainless steel, Ultra Flo mufflers, ’08–’13 Dodge Challenger SRT8² 39484 Summit $657.97 Mr. Norm’s Calibration File, baseline for supercharger kit, use with DiabloSport hand-held tuner — Westech $125.25 RCV HalfShafts, shorten existing RCV parts to fit Dynatrac Pro60³ Custom Westech $275.00 HalfShafts, rebuild CV joints Custom Westech $625.00 Total $6,466.99

NOTES: ¹Although Westech built up the assembly from individual components, the price shown is for a typical complete center-section assembly, including the nodular-iron housing, gray powder-coated finned-aluminum differential cover, 35-spline Truetrac Dana 60 limited-slip differential, 3.54:1 ring-and-pinion (up to 7.17:1 available), billet 1350-series U-joint yoke, 35-spline/1.5in-od CV-style outer stub-axle shafts, and miscellaneous bearings and retainers. A fully-complete kit from Dynatrac including halfshafts and wheel bearings costs $6,286.00. ²Not all parts of this kit were used (see text). ³Correct-length RCV halfshafts can also be ordered directly from Dynatrac.

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at pitstop@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.