One of the pioneers in the aftermarket suspension business is Brent VanDervort. As a kid he and his brother built a Model A pickup and it evidently got the creative and mechanical juices flowing because a string of more than 20 cars followed, not to mention the countless others he helped friends put together.

With his mechanical expertise and a business management degree Brent took what seemed to be the next logical step and opened Fatman Fabrications in 1985. Right out of the box the fledgling company developed a reputation for no-nonsense components that worked as they should, were affordable, and easy to install. Nearly 30 years later not much has changed in that regard, although the number of products certainly has.

Today Fatman offers an array of suspension kits and complete chassis for a wide variety of cars and he hasn’t forgotten those who are building trucks. A great example is the complete 1955-1959 Chevy truck chassis. Built from 2x5x.188-inch rectangular tubing for strength, the framerails are mandrel bent for accuracy; which means everything that attaches to the frame fits as it should. A variety of suspension options, as well as standard and Pro-Street configurations, allow customers to build a truck their way.

While Fatman’s new chassis offers outstanding ride and handling characteristics, something very special can be added to them as well—a VIN number. As an Accredited Manufacturer, Fatman Fabrications can supply a legal VIN number and a Statement of Origin to help title a complete reproduction vehicle (always check with your state DMV office for particulars).

1. Fresh from Fatman Fabrications, this new chassis is a fitting foundation for any ’55 to ’59 Chevy pickup. Early Chevy pickup and Ford fans needn’t worry, Fatman has frames and suspension components for those too.

1. Fresh from Fatman Fabrications, this new chassis is a fitting foundation for any ’55 to ’59 Chevy pickup. Early Chevy pickup and Ford fans needn’t worry, Fatman has frames and suspension components for those too.

Recently we took delivery of a Fatman Chevy truck frame that will find its way under our very own Jason “Installation Jason” Scudellari’s pickup project. As the guy in charge of Source Interlink Media’s Tech Center, Jason knows how to assemble a first-rate chassis. For steering, he chose a new Billet-Power rack-and-pinion unit from Flaming River. Made with all-new components, these new racks are lighter and stronger than OEM—and they’re better looking too.

For suspension at all four corners coilovers from RideTech got the nod. Well known as a leader in air spring suspension under the name Air Ride Technologies, RideTech is the same company with a new name and an ever-expanded product line. Their new coilovers are monotube gas pressure units with impact forged aluminum bodies and are available in fixed valve, rebound single adjustable, or triple adjustable versions.

With all the parts on hand it didn’t take long to put them in place, owing not only to Jason’s excitement to get his truck on the road, but the fact that everything fit like it should. This is a true state-of-the-art truck chassis and the cool thing is you can have one just like it.

2. This jig is used for truck frame assembly. Specific stops are bolted in place to ensure proper alignment for welding. A center string line is used as a double check to be certain the frame remains square and true as welding takes place.

2. This jig is used for truck frame assembly. Specific stops are bolted in place to ensure proper alignment for welding. A center string line is used as a double check to be certain the frame remains square and true as welding takes place.

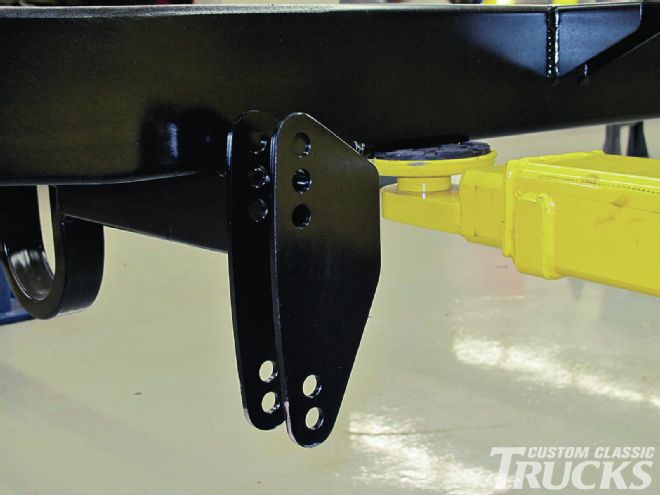

3. A look at the bottom side reveals the quality of welds attaching the front crossmember to the rails. The bracket is one of the rack and pinion mounts.

3. A look at the bottom side reveals the quality of welds attaching the front crossmember to the rails. The bracket is one of the rack and pinion mounts.

4. This is the Pro-Link style crossmember that forms the basis for the rear four-bar. For Pro Street trucks the coilovers can be mounted inboard on the frame for maximum tire space.

4. This is the Pro-Link style crossmember that forms the basis for the rear four-bar. For Pro Street trucks the coilovers can be mounted inboard on the frame for maximum tire space.

5. Scott Hobbs, one of Fatman’s lead fabricators, locates a transmission crossmember. Drilling the chassis for the fasteners next.

5. Scott Hobbs, one of Fatman’s lead fabricators, locates a transmission crossmember. Drilling the chassis for the fasteners next.

6. With the new chassis on the hoist in the Tech Center, Jason begins assembly by attaching the lower A-frames. The small C-notch is for steering rack clearance.

6. With the new chassis on the hoist in the Tech Center, Jason begins assembly by attaching the lower A-frames. The small C-notch is for steering rack clearance.

7. To ensure the front suspension stays in alignment, the upper A-arms attach to vertical plates. This allows the use of shims for caster and camber adjustments rather than the slots and sliding bolts often seen.

7. To ensure the front suspension stays in alignment, the upper A-arms attach to vertical plates. This allows the use of shims for caster and camber adjustments rather than the slots and sliding bolts often seen.

8. Jason used spindles from Wilwood, they’re available stock or with a 2-inch drop—these are dropped.

8. Jason used spindles from Wilwood, they’re available stock or with a 2-inch drop—these are dropped.

9. RideTech’s shocks are anodized to prevent corrosion and come with 5⁄8-inch bore x 1-inch Kevlar-lined bearings for noise-free operation.

9. RideTech’s shocks are anodized to prevent corrosion and come with 5⁄8-inch bore x 1-inch Kevlar-lined bearings for noise-free operation.

10. Another unique feature of the RideTech coilovers are the pinch clamp height adjusters. They use fine threads and Delrin spring washers to allow bind free pre-load adjustments.

10. Another unique feature of the RideTech coilovers are the pinch clamp height adjusters. They use fine threads and Delrin spring washers to allow bind free pre-load adjustments.

11. Fatman’s shock towers allow for the utmost in flexibility for the builder as the same bracketry allows the use of coilovers or RideTech ShockWaves.

11. Fatman’s shock towers allow for the utmost in flexibility for the builder as the same bracketry allows the use of coilovers or RideTech ShockWaves.

12. Flaming River’s new Billet-Power rack offers more than 6 inches of travel and it’s 12 pounds lighter than similar OEM units.

12. Flaming River’s new Billet-Power rack offers more than 6 inches of travel and it’s 12 pounds lighter than similar OEM units.

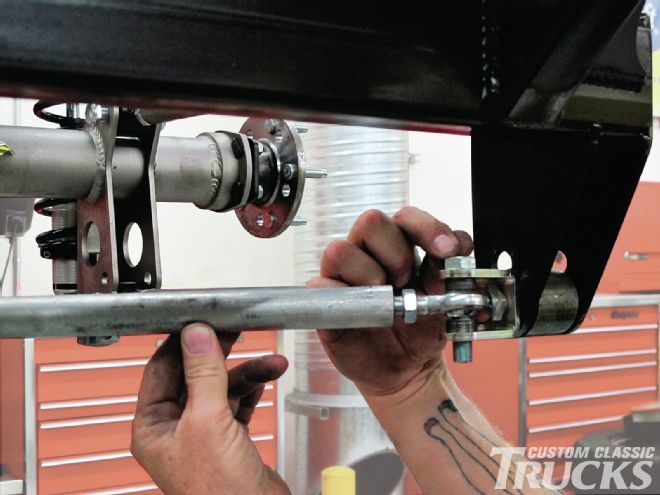

13. Billet-Power racks use a 1-inch diameter rack shaft for increased strength over OEM Mustang/Pinto racks. Made in the USA, Power Racks are fluid and pressure tested then certified before being shipped.

13. Billet-Power racks use a 1-inch diameter rack shaft for increased strength over OEM Mustang/Pinto racks. Made in the USA, Power Racks are fluid and pressure tested then certified before being shipped.

14. In the rear Jason opted for four-link style brackets to allow for suspension tuning.

14. In the rear Jason opted for four-link style brackets to allow for suspension tuning.

15. Along with the four-links, a diagonal track bar locates the rearend laterally.

15. Along with the four-links, a diagonal track bar locates the rearend laterally.

16. Fatman’s rear four bars are made from tubing strong enough to handle high-horsepower applications. Each has a threaded urethane end to allow for pinion angle adjustments.

16. Fatman’s rear four bars are made from tubing strong enough to handle high-horsepower applications. Each has a threaded urethane end to allow for pinion angle adjustments.

17. Under the rear of the truck is the Currie rearend we showed under construction in the May issue of CCT.

17. Under the rear of the truck is the Currie rearend we showed under construction in the May issue of CCT.

18. Another pair of RideTech coilovers are found in the rear; they come with a stainless steel spanner wrench that attaches to a 3⁄8 ratchet allowing coil adjustments in a tight area.

18. Another pair of RideTech coilovers are found in the rear; they come with a stainless steel spanner wrench that attaches to a 3⁄8 ratchet allowing coil adjustments in a tight area.

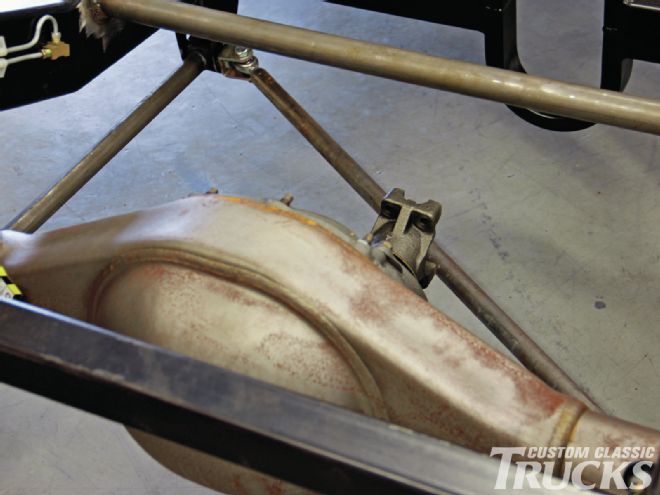

19. Rather than a Panhard bar a diagonal locator is used. It attaches to the bottom left four-link bolt on the chassis and the bottom bolt on the rearend on the opposite side.

19. Rather than a Panhard bar a diagonal locator is used. It attaches to the bottom left four-link bolt on the chassis and the bottom bolt on the rearend on the opposite side.

20. One of the advantages of a diagonal link is that it normally allows more room for the exhaust to go up and over the rearend.

20. One of the advantages of a diagonal link is that it normally allows more room for the exhaust to go up and over the rearend.