Before we get into showing you how we upgraded the suspension on our A-body, here's a little background into why we did it. We covered the build and installation of the 427-inch stroker small block into our '68 Valiant in the June 2011 issue. With the new 427 under the hood, the car was so fast that some upgrades to the chassis were necessary. It literally became a safety issue. Let's face it, running 150 mph in a '68 Valiant has a way of forcing you to focus your attention onto items such as the suspension, brakes and oiling system!

Weight Reduction

While these A-Body cars are a little lighter than either the B or E-Body cars, they are still heavy compared to some of the other cars that show up to race on open track days. The power of the 427 inch engine does help to equal things out a bit, but weight reduction has always been one of the cheapest ways to go faster. Not only will a lighter car accelerate faster, but it will corner harder and stop faster than a heavy car. Knowing this, we decided to take a serious look at each component on the car to see if there was any opportunity to shave a few pounds. Because these cars are naturally nose-heavy, we focused most of our weight reduction efforts at the front of the car. We were able to save big chunks of weight with the aluminum cylinder heads and the aluminum transmission case. We found smaller weight savings by switching to Schumacher motor mounts, cutting some bracing out of the hood, changing anti-sway bars, swapping headers, and installing new brakes.

Suspension

The suspension under the Valiant is stock configuration, although very few original parts are still in place. The original K-frame and suspension was replaced years ago with parts from a '73 A-Body car. The later model anti-sway bar was an excellent design, but the factory bar is too soft for track use, so it was replaced with a 11⁄8-inch diameter bar. This larger bar worked fine but was very heavy, so we went looking for a replacement.

<strong>1.</strong> These three anti-sway bars all fit the 1973 style K-frame in our Valiant. The factory bar at the top doesn’t have enough roll resistance for the cornering speeds that this car is capable of. The black bar in the middle worked fine but it weighs 14 pounds. The tubular Hellwig bar at the bottom of the picture only weighs eight pounds. Six pounds might not sound like a substantial weight savings, but when added with all of the other weight shaving, it adds up.

<strong>1.</strong> These three anti-sway bars all fit the 1973 style K-frame in our Valiant. The factory bar at the top doesn’t have enough roll resistance for the cornering speeds that this car is capable of. The black bar in the middle worked fine but it weighs 14 pounds. The tubular Hellwig bar at the bottom of the picture only weighs eight pounds. Six pounds might not sound like a substantial weight savings, but when added with all of the other weight shaving, it adds up.

With a little bit of research we found out that Hellwig had a selection of lightweight Mopar anti-sway bars fabricated from high strength steel tubing. By increasing the outer diameter of the bar, a tubular anti-sway bar is both stiffer and lighter than a solid bar. Hellwig offers 1-1⁄4-inch bars as well as 1-1⁄8-inch tubular style anti-sway bars. We decided to go with the 1-1⁄8 version even though that meant that our front roll stiffness would decrease slightly. We felt that a slightly softer front bar would work fine once we had finished with our other weight reductions up front.

An adjustable rear anti-sway bar was also fitted to the car to provide additional rear roll stiffness. This particular rear bar was custom built to work with the low ride height, but vendors such as Firm Feel offer similar rear anti-sway bars. This bar was mounted on the frame in an effort to reduce un-sprung weight. The end link location on this bar is adjustable, which allows us to increase the rear roll stiffness for autocross events.

<strong>2.</strong> The Hellwig kit included all of the required mounting hardware, but we decided to make our own extra heavy-duty end link spacers from one-inch diameter aluminum. These large diameter spacers reduce compliance in the bushings and slightly increase the roll resistance.

<strong>2.</strong> The Hellwig kit included all of the required mounting hardware, but we decided to make our own extra heavy-duty end link spacers from one-inch diameter aluminum. These large diameter spacers reduce compliance in the bushings and slightly increase the roll resistance.

Brakes

With the car capable of 150-plus-mph top speeds on the straights we knew that the brakes were going to be heavily taxed on this car. Previously, the car was fitted with a brake kit that utilized homemade brackets to support the 13-inch OE Viper calipers and rotors. The home built 13-inch kit worked fine, but the Viper rotors were very heavy due to their cast iron construction. Baer Brakes builds several brake kits for Mopar vehicles that can easily handle the speed and power of our A-Body, so we called their tech line for a recommendation. What we found was that while Baer had plenty of kits which would fit our car, all of their standard kits are designed to work with Mopar type wheels. Our Valiant has been fitted with 17x9 "Bullit" wheels, and the wheels need to be located very precisely in the wheel wells to clear the fenders. After a short discussion with the guys at Baer, they suggested that we use parts from their Builder Series to create a customized solution. The good news was that the Baer rotor and calipers were six pounds lighter per wheel when compared to the Viper brake setup.

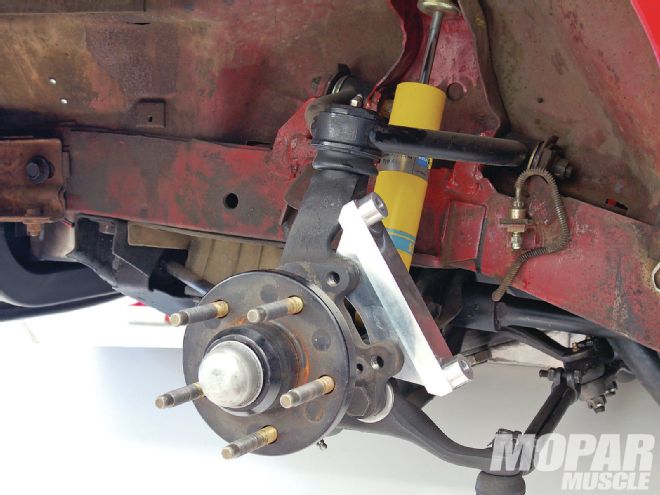

<strong>6.</strong> We procured a set of Baer calipers and rotors through their Builder Series program. Using our own hubs in conjunction with the Builder Series parts, allowed us to put the wheels in the exact location necessary to run the 275/40-17 tires up front. The two-piece Baer rotor is 13 inches in diameter and is 11⁄4 inches thick. The aluminum caliper uses Mustang dimensions in order to work with the Bullit wheels. These rotors weigh 18 pounds each, which is 5 pounds lighter than the Viper rotors that were on the car.

<strong>6.</strong> We procured a set of Baer calipers and rotors through their Builder Series program. Using our own hubs in conjunction with the Builder Series parts, allowed us to put the wheels in the exact location necessary to run the 275/40-17 tires up front. The two-piece Baer rotor is 13 inches in diameter and is 11⁄4 inches thick. The aluminum caliper uses Mustang dimensions in order to work with the Bullit wheels. These rotors weigh 18 pounds each, which is 5 pounds lighter than the Viper rotors that were on the car.

In order to put the wheels in the necessary location, we also needed to have a set of custom hubs machined to our specifications. The hubs were designed to fit the large wheel bearings on our late model spindles, as well as having the correct nose dimensions to fit and locate our wheels. Once the design was final, we had the hubs machined by a local machine shop and then anodized for corrosion protection. With the hubs back in hand, we pressed in a set of extra long wheel studs and installed high quality Timken wheel bearings.

In an effort to improve brake feel, as well as to reduce weight, a rear disc-brake kit for the 8-3⁄4 rear end was sourced from DoctorDiff. The DoctorDiff kit is a lightweight setup using 10-3⁄4-inch diameter rotors. The key to the DoctorDiff kit is a billet aluminum caliper-adapter bracket that not only locates the caliper, but also provides the proper spacing so the original bearing adjuster can be used. By using the stock adjuster and seals, this disc brake kit is compatible with the factory style tapered roller axle bearings. We really did not want to change over to a ball bearing type of axle bearing because the tapered roller bearings are better suited for the side loads seen in a road race car.

<strong>7.</strong> The custom hub and caliper bracket are visible once the rotor and caliper are removed. The hub is made from aluminum and is designed to work with Bullit wheels. The caliper bracket was custom machined from aluminum bar stock.

<strong>7.</strong> The custom hub and caliper bracket are visible once the rotor and caliper are removed. The hub is made from aluminum and is designed to work with Bullit wheels. The caliper bracket was custom machined from aluminum bar stock.

Oil Pan Oil control has been an issue with this car for some time now. The high G-forces encountered on a road race course really raise havoc with the oil in the pan as well as in the valve covers. The engine has been fitted with several different oil pan designs over the year, but none of them have worked quite as well as hoped. The biggest problem which we've seen at the track is a lack of oil pressure while rounding long sweeping corners. Our theory is that the oil in the sump is being trapped up against the side of pan. If the corner is long enough, the pickup in the pan is eventually uncovered and the oil pressure drops. The Valiant has been fitted with a three quart Accusump system in an attempt to provide additional oil supply during the long corners, but even that hasn't prevented occasional loss of oil pressure.

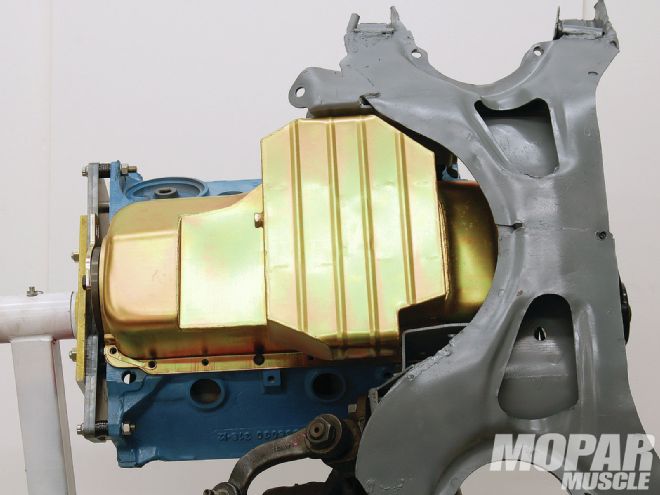

<strong>11.</strong> Milodon has just released a road race oil pan for small block Mopar engines. The Milodon pan has a large kick out type sump with five trap doors to keep the pickup covered with oil. Milodon highly recommends using one of their windage trays with the road race pan. The Milodon road race pan was made as large as possible while still fitting into the tight confines of the 1973 type K-frame. The spool type motor mounts on the late model K-frame really limit the space available for a large sump on the oil pan.

<strong>11.</strong> Milodon has just released a road race oil pan for small block Mopar engines. The Milodon pan has a large kick out type sump with five trap doors to keep the pickup covered with oil. Milodon highly recommends using one of their windage trays with the road race pan. The Milodon road race pan was made as large as possible while still fitting into the tight confines of the 1973 type K-frame. The spool type motor mounts on the late model K-frame really limit the space available for a large sump on the oil pan.

Milodon has had an excellent big-block road race oil pan available for the B and E-Body cars on the market for many years, but there hasn't been a small-block version available until recently. Milodon released a small-block road race pan at the 2010 SEMA Show, which fits the production K-frame in A-Body cars as well as the B and E-Body cars. The new Milodon pan has a large T-style sump located ahead of the steering linkage. The central pickup area in the sump is surrounded by trap doors to control the oil during cornering, braking, and acceleration. The sump on this Milodon pan was made as large as possible to fit into the chassis without hanging down below the K-frame.

Chassis

There is a tradeoff between chassis rigidity and total weight in any track car, and this one is no different. The lower radiator support from XV Motorsports has been proven to be a key upgrade for Mopar vehicles, but it does add some weight to the car. Adding weight is always cause for concern, especially when the weight is ahead of the front wheels. Given that this car is already nose heavy, we were reluctant to add any more weight that far forward. But the benefits of tying the frame rails together at the front of the car have been proven by XV on their four post shaker, so we decided to move forward and weld the support in place. With a little bit of extra fabrication work, the brace installation came out looking very clean and original. This car uses a radiator which is larger than stock, so the brace was slightly modified to provide additional clearance for the tanks. Once the support was painted black and the bumper re-installed, it is virtually impossible to see that it is there.

<strong>12.</strong> The radiator support from XV Motorsports is barely noticable even with the front bumper removed. A close up view of the XV Motorsports radiator support shows how the tubing is welded to both the frame structure as well as the core support sheet metal. The extra welding helps to tie the front of the frame together to improve chassis rigidity.

<strong>12.</strong> The radiator support from XV Motorsports is barely noticable even with the front bumper removed. A close up view of the XV Motorsports radiator support shows how the tubing is welded to both the frame structure as well as the core support sheet metal. The extra welding helps to tie the front of the frame together to improve chassis rigidity.

Transmission and Rear-end

As part of our weight reduction effort, we went through the car and weighed all of the heavy components. One item we really noticed during this process was the original four-speed transmission, with its total weight of 117 pounds. This weight is carried fairly low in the car, but it is ahead of the center of gravity, so we were interested in reducing this weight as much as possible. We were aware of the weight savings possible with the aluminum case from Passon Performance, so we gave them a call. Passon developed their version of the A833 case several years ago, and it has been a very popular item for Mopar vehicles. Not only does Passon have aluminum versions of the main case available, but they also offer an aluminum side cover and an aluminum tail shaft. Our total weight savings after a transmission rebuild was right at 35 lbs.

Previously, the car was setup with a 3.23 rear gear and a close-ratio 2.47 first gear set in the iron A833. With the additional power of the new motor, the decision was made to switch to a 2.94 rear end gear. Combining this high rear end ratio with the close ratio set in the transmission gearing was going to make the car difficult to launch smoothly during street driving so we decided to go with a wider ratio gear set. To accomplish this, a 2.66 first gear was installed in the Passon case using a 308 front bearing and a 5.125-inch bearing retainer. Incorporated into the rear gear change was a swap to a 1967 B-Body 8-3/4 rear end. This was done to facilitate using the higher offset wheels at the rear. The slightly wider B-Body rear end places the high-offset wheels squarely in the rear wheelwells without the use of spacers.

<strong>13.</strong> The aluminum transmission case from Passon Performance weighs 24 pounds. With an aluminum case and cover, the total weight of our A833 transmission is only 81 pounds. This is a full 35 pounds lighter than the original four speed transmission that came out of the car.

<strong>13.</strong> The aluminum transmission case from Passon Performance weighs 24 pounds. With an aluminum case and cover, the total weight of our A833 transmission is only 81 pounds. This is a full 35 pounds lighter than the original four speed transmission that came out of the car.

The Cash Outlay

PartPart NumberPrice Hellwig Sway bar55905$160.00* Baer six-piston brake kitCustom$2,588.00* Brake padsXP-12$205.00* Dr. Diff rear disc brake kitEcono$525.00* Milodon oil pan31590$420.00* XV Motorsports radiator support20-1423$90.00* Passon's transmission caseCall for your application$750.00*

*Prices as of the time we did the work. They might have changed, or they might not have.