Race car suspensions and setups have gone through many changes in recent years. Ever since the onset of the "Big Bar Soft Spring" era, racers have found themselves trying to go softer and softer with their suspensions to achieve that perfect balance. Everybody is doing it, and if the Cup guys are doing it must be better, right?

Much of the time, however, racers are disappointed with the results as the cars just don't seem to react logically. If the car is tight, you soften the front springs even more...right? This time that doesn't seem to work, so confusion and frustration usually set in, sending you back to your traditional setups.

Magically, the car's feel is back, and it's fast again. So what was missing? They say "Why didn't it work for me?" In my experience it's all about the understanding of one basic dynamic that most racers don't have the ability to measure: Dynamic Wheel Load Distribution.

Dynamic Wheel Load Distribution is the distribution of loads on the four tires as the car turns and all of the load transfer has taken place. If we can gain this one piece of missing information, the puzzle will begin to unfold, and you will begin to understand why your race car reacted the way it did with the new style setups.

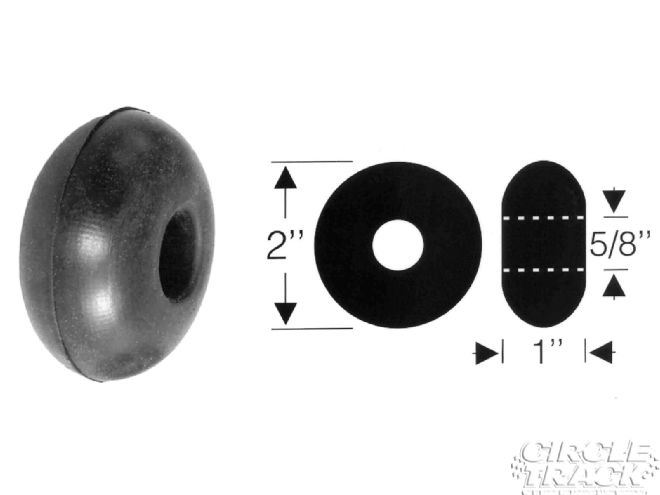

Bump rubbers come in various densities and sizes. The idea is to produce a "spring" rate that will work in conjunction with the other springs in the car to produce a balanced setup with soft initial travel and then a much stiffer spring rate in the turns.

Bump rubbers come in various densities and sizes. The idea is to produce a "spring" rate that will work in conjunction with the other springs in the car to produce a balanced setup with soft initial travel and then a much stiffer spring rate in the turns.

Many have said that the Big Bar Soft Spring setup only achieved its gains from the added downforce created from a better, lower, and flatter body attitude. While those advantages definitely have merit, they are still overlooking the very reason aero downforce makes a race car faster. Here again it all comes down to wheel load distribution.

So, now you can begin to see that when previously trying the Big Bar Soft Spring setup, the real culprit to the failure was the redistribution of wheel loads. In actuality, this is a lack of or reduction in those wheel loads as you went softer and softer on the front springs. The solution to this problem can be solved in several different ways so that you can have the advantages of better aero downforce, as well as maintain a neutral balanced setup.

Bumpstops

Bumpstops are one of the best methods of achieving this balance. When using bumpstops, you install a stack of properly selected bumpstops on one or both front shock shafts. You then select a front spring and sway bar package that will give you the best on-track body attitude.

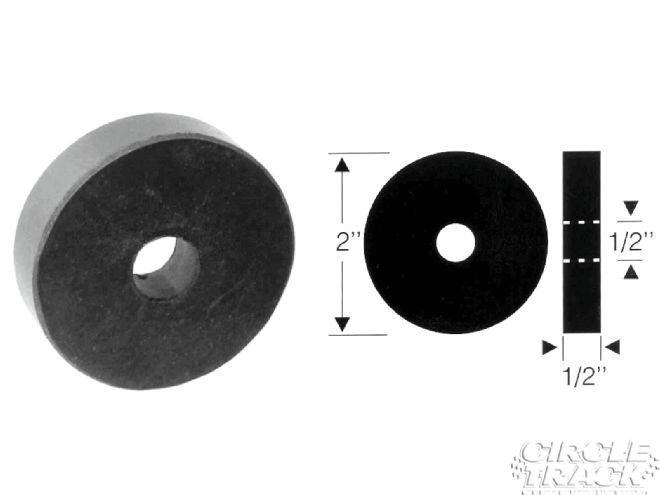

This rubber represents a much stiffer rate that is close to, but not really a packer. This can be used in conjunction with the round rubber design.

This rubber represents a much stiffer rate that is close to, but not really a packer. This can be used in conjunction with the round rubber design.

Now, the key is knowing and achieving the proper wheel load in critical parts of the corner to balance the chassis handling. We do this by selecting different hardness ratings in the bumpstops themselves, and by adding spacers or packers to alter the timing and engagement points of the shock body to the bumpstop stack.

This in effect creates a specific amount of wheel load for each wheel, based on a given amount of suspension travel to achieve that optimum body attitude and optimum distribution of wheel loads at the same time.

As an example: A traditional balanced setup with a 600-pound RF spring, produces 1,700 pounds of load at 3 inches of shock travel. Alternatively, a balanced bumpstop setup might utilize a 300-pound RF spring, but engaging a bumpstop stack at 2 3/4 inches of shock travel achieves 1,700 pounds of wheel load at the same 3 inches of max shock travel. As you can see, both setups are now achieving the same wheel load at max travel keeping the balance very similar, but one very important difference exists.

Phantom Bump Stops has created an adjustable fixture to house the bump rubber that can be preloaded to make small changes in the rate.

Phantom Bump Stops has created an adjustable fixture to house the bump rubber that can be preloaded to make small changes in the rate.

The bumpstop setup with softer springs and bigger bar reaches its optimum load sooner, and maintains it for a much longer time frame through the corner. This fact has several major advantages.

The camber will be at its optimum settings for maximum grip much earlier in corner entry, through center, and remain longer through corner exit. The overall center of gravity of the car will also remain lower throughout the entire lap, also enhancing corner speed. Lastly, softer springs in the front will be in a more preloaded state, which can sometimes enhance rear weight transfer, further helping forward bite.

The simplicity of a good bumpstop system and ease of fine adjustments make bumpstops my number one choice for a suspension package wherever rules allow.

This adjustment tool is used to make quick and easy changes to the preload on the bump rubber. Adjusting the preload is essentially the same as changing the spring rate of the rubbers without having to remove and replace them when slight changes are needed.

This adjustment tool is used to make quick and easy changes to the preload on the bump rubber. Adjusting the preload is essentially the same as changing the spring rate of the rubbers without having to remove and replace them when slight changes are needed.

Drivers first impressions of a well-balanced bumpstop setup are usually that they have much more feel in the front of the car. The cars usually respond very quickly to small inputs in steering, and less overall steering input is usually required.

Bumpstops can have an advantage over coil-binding as well. With bumpstops you can fine tune the weight distribution and crossweight settings much more easily without changing any critical dynamic chassis heights or stop heights. Bumpstops also can provide much more compliance than the coil-bind setup making it a better choice when rough track surfaces are a concern.

In closing, a well balanced bumpstop setup using soft springs is much closer in relative wheel rate to our older traditional setups than many ever realized. Understanding and applying these traditional principles in a new way could be all that's needed to help keep you ahead of your competition!

A New Line of Bumpstop Products

To take this technology further, Mercer Race Car Engineering has partnered with Steele Rubber Products to develop a brand-new line of bumpstop products.

Phantom Bump Stops offers a variety of different bumpstops and accessories, as well as spring rubbers. It also offers a brand-new, Preload Adjustable Bumpstop System that gives racers more adjustability in their packages than ever before.

Once the shock is fully compressed, the shock body contacts the bump rubber housing and the spring rate at that corner of the car goes from the installed spring rate to the bump rubber rate. The actual rate of the bump rubbers in most cases is the same or exceeds old-school setups.

Once the shock is fully compressed, the shock body contacts the bump rubber housing and the spring rate at that corner of the car goes from the installed spring rate to the bump rubber rate. The actual rate of the bump rubbers in most cases is the same or exceeds old-school setups.

This new system contains a preload adjustable cup or canister that the bumpstops are contained in (see the pictures on the following page). That provides the ability to preload the bumpstop stack to change the effective rate of the contained bumpstops. To create more load and stop travel sooner, you now only need to increase preload in small increments instead of adding packers as previous systems would require.

This allows fine-tuning the dynamic travel or stop height without changing the timing of engagement or air gap. It also provides the ability to run much softer bumpstops than previously possible by allowing you to set the desired travel distance into a bumpstop stack by changing the preload.