The legend of Project X continues to grow, and thanks to the people at General Motors, this latest chapter in the life of American's favorite project car promises to be the best one yet. As GM Performance Parts was bolting together the first-ever prototype Anniversary 427 big-block, the crew at GM Performance Division set out to separate this generation of Project X from all others that came before. Last time, we took you deep within the heart of GM, the Design Center in Warren, Michigan, for a behind-the-scenes look at how the world-class technicians of GM Performance Division used advanced math data and vehicle dynamics to meld the 50-year-old frame of Project X with the vibrant, young front chassis and suspension of a 2008 C6 Corvette. And, while that project set the bar for the level of expertise (as well as passion) that was lavished on the car, it left us wondering what other surprises this team of master car builders had in store for Project X.

When Project X arrived in Detroit, Mike Copeland, the drill sergeant of this General's army, demanded that each person who was going to be assigned to the build take a turn behind the wheel. He did this not just to motivate an already lathered-up squad, but he wanted their expert "seat of their pants" interpretation of where the car was, and what the team could do better. Without question, the rear suspension was one of the areas on Project X they determined could be done better.

Now, understand that Project X came to GM equipped with your typical ladder bar rear suspension with some adjustability, and carried a Ford 9-incher into battle. Not an uncommon setup, but it certainly leans toward the "race" side of the gallery. For this build, Copeland wanted something that took Pro Street to a functional level that Project X had never before seen. While the ladder bars were great for 60-foot times, the lack of compliance on road surfaces as well as poor handling characteristics in anything but a straight line didn't match the progressive, modern car that Project X was destined to become.

Here's what the GM Performance Division team started with: your basic Ford 9-inch rearend with ladder bars. First surprise-the team found that the wheelbase on Project X was incorrect, likely from the ladder bar installation.

Here's what the GM Performance Division team started with: your basic Ford 9-inch rearend with ladder bars. First surprise-the team found that the wheelbase on Project X was incorrect, likely from the ladder bar installation.

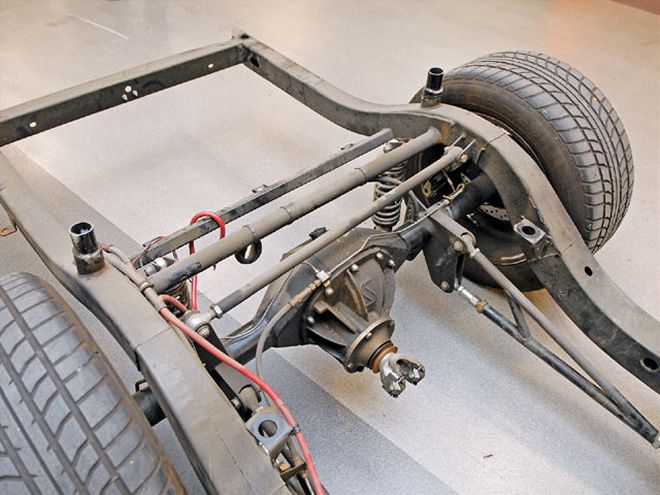

The ladder bars had to go! But what do you replace them with? The GM Performance Division crew chose a triangulated four-link with coilover struts held within a narrowed stock frame with a Strange center section. The four-link offers many advantages over the ladder bar setup. First, it's stronger, especially with the additional triangulated material added into the seams of the 2.5 inches that are narrowed for tire fitment. Second, the four-link is much more compliant on the road, offering up an incredibly smooth ride. Third, the four-link is infinitely adjustable for custom applications. And finally, the four-link is a much more modern suspension that offers the finished vehicle good handling and strength all in one package.

Like the entire car, the rear suspension was first designed in math, then the GM engineers got down to incorporating the upgraded suspension within the confines of the '57 Chevy frame. We've also shown you how GM started with the desired back tire (a 16-inch-wide Mickey Thompson) and fit it in the car before they ever laid a torch to it. And while the team certainly took advantage of the millions of dollars worth of equipment at their disposal, a simple wooden fixture that mimics the profile of the tire allowed for a check of tire clearance at any given suspension travel point. We've put together a sequence of photography that will help illustrate how the rear suspension was developed, engineered, and finally built into the car. And for all of you aspiring '57 Chevy builders out there, you can find the actual math data for this build on our Web site at www.popularhotrodding.com.

Next month, we'll be back with a series of small vignettes that detail just a few of the hundreds of custom touches that have been engineered into this car. Some are custom fabrication work, others are modern GM engineering applied to a 50-year-old car, and other areas of this build are simply car-building mastery that you'll only find from car builders of this caliber.