Some people remember where they were when they heard Kennedy was shot. Others, when Neil Armstrong landed on the moon or the Dow hit 10,000. Me? I'm just a little bit different; I remember things like seeing my first Model A rear crossmember cover. Equal parts industrial chic, universal, and, most importantly, useful beyond merely covering a rear crossmember in the trunk of a car, I immediately fell in love. Never mind that it already had an intended purpose; I had to have that cover simply for the potential of what else it could be. In fact, I didn't even know what the thing was until I sidled up to the counter to buy it.

Despite building several cars in the half a dozen or so years I owned the thing, I never quite found the right use for it. For example, it seemed a bit too narrow for a tool tray yet too shallow for a spare-tire well. After inventing a few scenarios where I could use the thing-some of which required building a car around it-I finally resigned myself to the idea that the two of us weren't quite the match I initially thought.

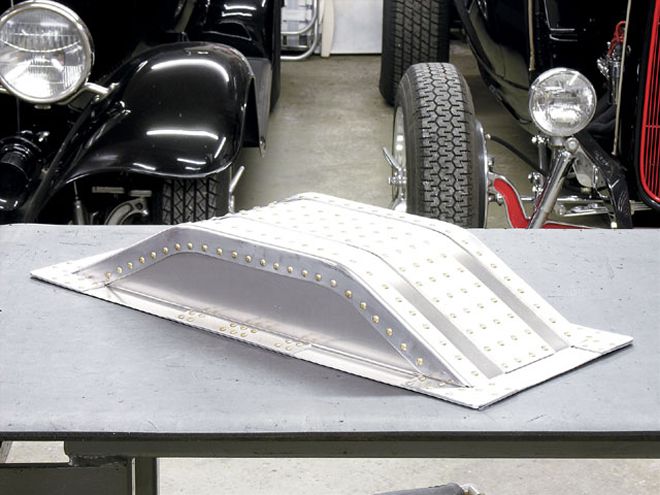

But after seeing what Frank Wallic made for a crossmember cover, my heart is once again aflutter. It's not for the fact that he made his cover from lightweight aluminum or that he gave to it that neat aviation aesthetic, although I admit they're influential factors. No, it's mostly because Frank's idea has great versatility. For example, while he copied the Ford part's general design, he wasn't necessarily locked into its dimensions. Change the size and orient the rivets to suit the application, and it'd make a dandy heater or A/C plenum housing, or, perfect for my current car's application, a blister to cover the hole made in my trunk's floor to accommodate the axlehousing. Need to relieve the firewall for a distributor but don't want to recess the whole thing? Scale this sucker down to fist sized and you're good to go, Jack.

The other element to this article's appeal is its user friendliness. Don't have a sheetmetal brake? No problem; most shops-think HVAC vendors, even-will cut and fold the parts and shrink edges for a small charge. Lack the tools to set solid rivets and don't like the look of blind rivets? Why not use small slotted stainless #8 or #10 round- or truss-head screws and brass nuts instead?

Point being, this is one of those projects that's as simple as you need yet as complicated as you wish. For those reasons-and also for the fact that this is a project within even my scope-I'm filing this memory somewhere between the first space shuttle flight and the advent of the personal