Shave a half-second off your 60-foot time when you . . .DIAL IN YOURCOIL SPRINGCAR

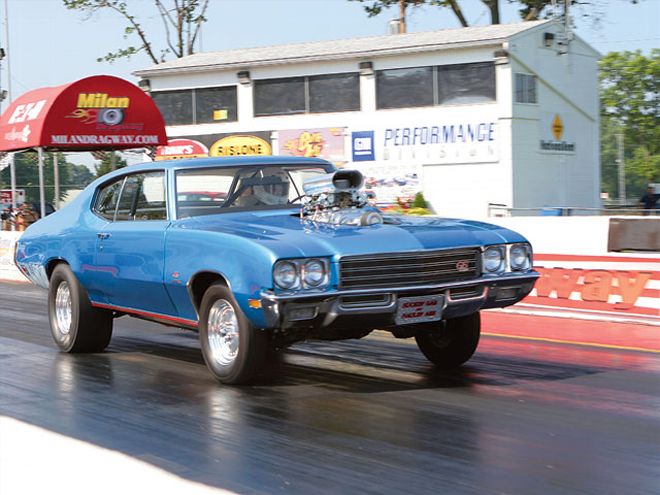

`Last month we pitched the stock rear suspension on a '71 Buick Skylark and installed a Dick Miller Racing (DMR) rear suspension system in an effort to get the car to hook at the racetrack. The factory coil spring suspension on the Skylark is the same as any GM intermediate from '64 to '88, including G-body, A-body Chevelle, Cutlass, or Fox Mustang, so the suspension theories and tuning explained here will work on any car with a similar setup. After we installed the kit we shaved 0.48 seconds off the 60-foot time. On a car with a healthy engine, that usually equates 0.50-1.5 off the e.t. and a straighter and safer run.

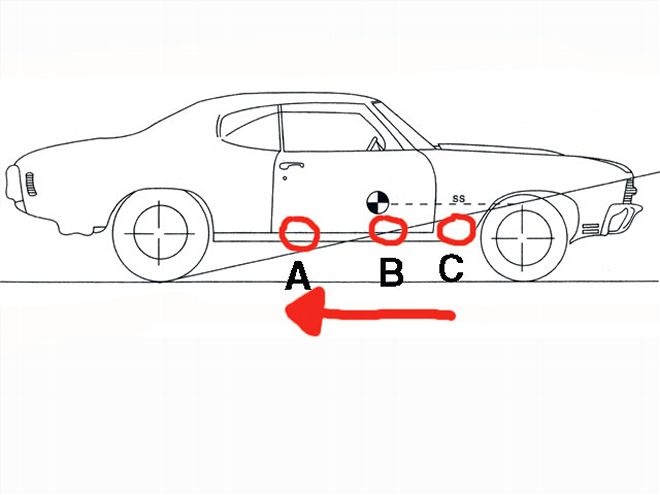

In order to understand what is happening here, we need to start with some science. When you punch the throttle on a rear-wheel-drive car, the engine, transmission, driveshaft, and pinion gear rotate counterclockwise as seen facing the rear of the car. This action rotates the axlehousing counterclockwise, planting the driver-side tire and unloading the passenger-side tire. In addition to the rotation of the axlehousing, the pinion is also rotated up as it tries to climb the ring gear, which is driven down. In rear-drive cars with coil spring suspensions, the upper and lower control arms keep the housing from moving and transfer the energy to the theoretical meeting point of the upper and lower control arm angles, called the instant center (IC). The neutral line is the diagonal from the contact patch of the rear tire through the point at the top of the front spindle level with the car's center of gravity. In relation to the neutral line, moving the IC above it makes the rear of the car rise on launch, and moving the IC below this line causes it to squat. Moving the IC to the rear of the car increases the violence of the hit on the tire, and moving it forward softens it. The ideal launch lifts the car in the rear after weight transfer and loads the tires equally without crushing them. That's what we're trying to do.

The original DMR rear suspension system has been around since 1995. Unlike the factory setup, the DMR upper control arms are adjustable for both suspension preload and pinion angle after they are installed on the car. Special brackets move the upper control arms above the differential housing with a special mount, moving the IC toward the rear of the car for more bite. In theory, you can get the same effect using the lower control arms, but Dick Miller tells us that you lose both the pinion angle and the preload adjustment, and the IC ends up higher in the vehicle, reducing leverage. The DMR kit also includes a taller spring with a softer rate to allow the car to rise when torque is applied yet retain its factory ride height. Factory springs are too stiff and do not allow the car to lift in the rear as easily as a car with softer springs would.

In 2002 DRM introduced adjustable lower control arms. The system now had the ability to move the axlehousing forward or rearward in relation to the body, in order to wedge larger tires under the car and allow four-wheel alignment changes to reduce rolling resistance. It all equals a quicker e.t. In 2005 the lower control arm was further improved with the addition of a track locator that connects the lower control arm (bracket) to the housing near the differential center section. This eliminates the left and right movement that tends to allow the rearend to steer the car.

The final part of the puzzle is the antiroll bar. When the front end lifts and the body twists to the right, that energy is redirected to the axlehousing via the antiroll bar to plant the tires evenly. DMR offers three different versions in order to accommodate cars with or without fuel tanks in the factory location, cars with full exhaust, and cars with rollcages.

When the entire DMR system is working together, expect to see dramatic drops in the 60-foot time, increased parts longevity, and photos of your car leaving like a Pro Stocker.

With all the rearend components in place, the first step was to make sure the axlehousing was square in the chassis. A simple measurement from a forward crossmember to a mounting point on each side of the housing ensured it was square. A measurement from the axle flange to the centerline of the car established that the housing was also centered in the car.

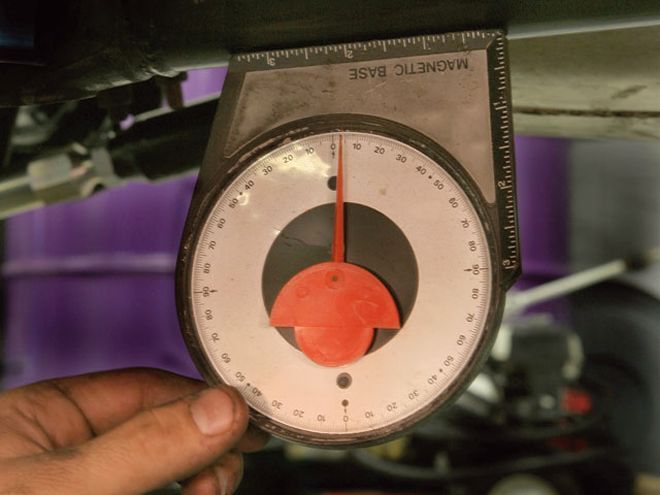

You want zero pinion angle when the car is accelerating, so depending on how much torque the car makes, you need to set the negative pinion angle using both upper control arms. The rule of thumb is 1-2 degrees of downward angle for a four-link car sitting on a flat surface. If you are making a lot more than 500 hp, the angle should be increased until you achieve zero angle at launch. Too much negative angle wastes horsepower.

Preload is set with the passenger-side upper control arm by drawing the corner of the housing up into the car and adding weight to that tire. If the car pulls right on the launch, shorten the control arm until it goes straight.

Special thanks to Milan Dragway for track time and Wheel to Wheel Powertrain for chassis dyno time! We couldn't have done this story without their help.

BSM Technologies specializes in rollcages, so while the car was in that shop getting the DMR sway bar and lower link struts welded in place, a custom rollbar was bent up. Here, the main hoop with a diagonal strengthening tube and crossbar is being put together. The crossbar will provide an anchor for the shoulder harnesses of the Crow five-point seatbelts being added.

The BSM bar was situated around the stock seats, headliner, and carpet to provide the required safety but not make the car unpleasant to run down to the cruise night. The main hoop was situated in line with the B-pillar trim to minimize its appearance in the vehicle. As a note, to be NHRA-legal, the door bars must pass the driver's arm at a point between the shoulder and the elbow.

The partnership of a skilled veteran like Mike Moran (left) with a dedicated enthusiast like the owner of this Buick, Mike Kunkle, produced some impressive results. If you are working to improve the performance of your street machine, set aside some funds to buy some rear suspension components. It's worth it.

DRAGSTRIP RESULTS WITH BLOWN '71 BUICK SKYLARK

Previous Fastest Pass: 12.02 seconds at 112 mph (60 feet = 2.05 second)

THE NEUTRAL LINE

This illustrates that as you move the IC toward the rear of the car, you also move it above the neutral line. That speeds the movement of the suspension and lifts the rear of the car, planting the tires.

DMR/Strange/Mickey Thompson Slicks-Equipped Fastest Pass:11.59 seconds at 114 mph (60 feet = 1.57 seconds)

Parts

Description/Part #/Source/Price

Double-adjustable shock absorbers, rear/S5064/Strange/$249.50

Rear suspension system/NOS-6028/Dick Miller Racing/$1,540.00

Rear sway bar/NOS-6413/Dick Miller Racing/$318.00

Single-adjustable shock absorbers, front/S5263/Strange/$149.00