Electronic fuel injection has come a long way in the last 30 years. Early aftermarket systems were complex, slow, and the user had to combine the unique talents of computer software user and accomplished engine tuner. The duo of high price and complexity kept all but the heartiest car crafters away. When the first adaptive systems came on the scene several years ago, many were skeptical, but these systems have now had the benefit of experience to become, for the most part, the simple-to-use-and-install systems they are advertised to be. We decided that what the world needed was an unbiased test of each of the four most popular systems to see just how easy they are to install and whether they can indeed deliver on the promise of better driveability and maybe a mileage improvement, too.

The four self-learning EFI systems we chose to evaluate are the MSD Atomic, FAST EZ-EFI 2.0, Edelbrock E-Street, and Holley Terminator EFI. All of these systems use a dedicated, standard 4150 flange throttle body with integrated injectors, making it a simple switch from a carburetor. That part is very easy. However, it is the implementation of a quality fuel-delivery system that is essential to a durable, trouble-free throttle body fuel injection (TBI) system. Our suggestion is to build the fuel-delivery system first and ensure its performance before you tackle the TBI.

This is also a good place to warn that these self-learning EFI systems are not a cure for a worn engine with two cylinders with burnt valves. On the other hand, we all know that most carbureted performance engines tend to run at a rich air/fuel ratio (AFR) nearly all of the time. Our experience with carburetors is that you can tune them to efficiently operate at steady-state levels like highway cruise or idle. The problem is that, unlike a boat, cars operate a majority of the time in transient conditions where the throttle is constantly moving. It is in these transient conditions where EFI can have a distinct advantage over a carburetor. When fitted with a wideband oxygen sensor (WBO2), it becomes obvious very quickly that carburetors suffer from very rich conditions in deceleration. All of the EFI systems we tested maintained a much leaner AFR when the throttle blades were closed and the rpm was descending, while a carburetor tends to nearly flood the engine with fuel. Combined with carburetor tuning that creates a rich condition on acceleration, EFI is probably at its best compared to a carburetor in transient, part-throttle, in-town traffic. We didn't simulate that specifically in our mileage test, but our guess would be that any of these systems would deliver far-superior around-town mileage, showing perhaps 2–4-mpg improvements when compared to a carburetor.

Our EFI test involved bolting on these four, self-learning EFI throttle-body systems to evaluate each in terms of how well they performed on our 496ci Rat '70 Nova test mule. We also evaluated these systems for ease of installation, how easy they were to configure, and how quickly each system could get your car running down the road with a feedback, self-learning fuel-injection system. That part was pretty easy because all of these kits performed equally well, a couple better than others in one particular test. Overall, the simplicity of the designs is what makes them attractive.

The reason for this simplicity is that in the past the end user had to create his own base fuel (and spark) maps. This first required a laptop computer along with a rather large knowledge base of engine fuel requirements at different engine speeds and loads, and knowledge of how to make all that work within the limitations and complexities of the EFI system's software. Even among the least-expensive EFI programs (like MegaSquirt), configuring the system demands specific software, computer, and engine expertise. Conversely, these newest, self-learning systems do not require a laptop, and anyone with newbie engine knowledge can program the simple inputs necessary to make the system work.

So while some may rant against the complexity of technology, here is an example of how the technology makes things easier and still delivers excellent performance for a reasonable cost while minimizing the technical expertise. We bolted each of these systems on our big-block and within a few minutes of completing the installation, we were driving down the road enjoying excellent throttle response.

As we completed the testing on these systems, everybody had the same question: "Which system is the best?" We think the answer depends upon what you want. That's not the question-dodging politician's answer that it sounds like. Instead, all four of these systems performed very well (with a couple minor hiccups), so from a performance standpoint, we would not hesitate to recommend any of these systems for the average sub-500hp street car. So then the question becomes less about performance and more about options or opportunities that one system offers that the others don't. As an example, if upgrading to a more sophisticated EFI system down the road is very important, then the Holley Terminator system offers great potential for expansion. If your plan is to bolt on an EFI kit and never touch the engine again except to change the oil and plugs once a year, then the least-expensive kit is probably the best. If you are an electronic geek who is attracted to the idea of an Android tablet included with the EFI system, then Edelbrock's E-Street system might be worth the price. If appearances are important, the MSD Atomic has by far the smallest, least-obtrusive wiring harness, since the ECU is integrated into the throttle body. And if your carbureted big-block already makes 800 normally aspirated horsepower, or you like the idea of converting to E85 fuel, then the EZ-EFI 2.0 is the only choice. We could go on, but you get the point. This test is perhaps the most complex we've taken on because of the dozens of similarities and variables across these four systems. We've done our best to illustrate as many ideas and opportunities as possible, but declaring a "winner" is something that only you can do. That's the beauty of being in this situation—you have four clear choices and you really can't make a bad decision. So let's get to the details.

Test Mule

When it came time to evaluate these TBI systems on our 496ci-powered '70 Nova test car, the old saying, "Beat it like a rented mule," became a war cry. We first assembled the Nova to test electronic overdrive transmission controllers ("In Control," Mar. '12) using the 496 we flogged for our big-block oval-port cylinder head test in the Mar. '08 issue. That combination made 590 hp and 620 lb-ft of torque with a set of Brodix oval-port heads and a mild Comp hydraulic roller camshaft. Next, we plugged in a boneyard refugee 4L80E with a TCI lockup 10-inch torque converter and finalized the drivetrain with a Currie-built 3.55:1-geared limited-slip 9-inch Ford rearend. We bolted on a set of P275/40R17 Toyo Proxes R888 soft-compound tires on a set of Weld Racing wheels and then discovered we needed a set of Competition Engineering Slide-A-Link traction bars to keep the rear tires firmly in contact with the pavement. We also previously had installed a Rick's Tanks stainless steel fuel tank with a Walbro in-tank electric pump that was capable of feeding our voracious Rat. With that, we were ready to take on these four TBI fuel-mixers.

We had previously equipped our Nova with a RacePak dash to give us data-logging capability, as well as a high-tech IQ3 digital dash. The dash gave us accurate GPS speed (lower center) and offered two additional AFR indications (one in each exhaust pipe—in lower left and right corners) to compare to the AFR indicated by the TBI system. The big number in the center indicates the number of GPS satellites we are using: 9.

We had previously equipped our Nova with a RacePak dash to give us data-logging capability, as well as a high-tech IQ3 digital dash. The dash gave us accurate GPS speed (lower center) and offered two additional AFR indications (one in each exhaust pipe—in lower left and right corners) to compare to the AFR indicated by the TBI system. The big number in the center indicates the number of GPS satellites we are using: 9.

Installation

The hardest part of installing any EFI system is building the fuel-delivery system. We've covered that in another section of this story. The next step is much easier—installing the WBO2 sensor. It's important to locate the sensor in the top half of the exhaust pipe to prevent cold-start condensation from possibly damaging the sensor. All of the kits supply a bung that is not difficult to install but does require welding. Make sure that the upstream portion of the exhaust leading to the WBO2 sensor is leak-free. This is critical to ensuring the WBO2 sensor works properly. With this accomplished, the only challenge left is finding a suitable home for the ECU and routing the wiring.

Installing the WBO2 sensor isn’t difficult, especially if you can remove the exhaust pipe from the car for the welding. Place the O2 sensor in the upper half of the exhaust pipe just behind the header collector, angled down slightly. Remember to leave enough room for the sensor wires to clear the floorboard. We MIG-welded our adapter into the pipe after drilling between a 0.875- to 1-inch hole in the exhaust pipe.

Installing the WBO2 sensor isn’t difficult, especially if you can remove the exhaust pipe from the car for the welding. Place the O2 sensor in the upper half of the exhaust pipe just behind the header collector, angled down slightly. Remember to leave enough room for the sensor wires to clear the floorboard. We MIG-welded our adapter into the pipe after drilling between a 0.875- to 1-inch hole in the exhaust pipe.

Unpacking a TBI box might be slightly intimidating because of all the wiring and connectors, but don't let it get to you. The connections are all pre-terminated, and each sensor has its own dedicated connector. You can't get them confused because they will only connect to the proper sensor, and each is labeled. There are roughly 10 sensor hookups to perform along with full-time 12-volt power and ground and a switched 12v trigger wire. You'll hear this more than once in this story, but it is essential that the constant 12-volt connection be hooked directly to the battery to minimize electrical noise. Hooking the wires to the battery uses it as a kind of filter or capacitor that minimizes electrical feedback that can otherwise cause untold ECU problems. Make sure that the switched 12-volt power source is live even when the engine is cranking. If not, the engine will probably not start. We chose to build a separate insulated terminal-fed power from a relay that offers system voltage whenever the ignition switch is turned on.

This may sound like we've over-simplified the process, but not really. You will still need to read the instructions. But the main thing that will require some installation time is professionally routing the wires. We'll admit that in the rush to install each of these systems, we just zip-tied each ECU wherever it was convenient because it was going to be quickly replaced by the next box, so we don't have a true installation time. Our best estimate would be four to six hours, not counting the fuel system. We installed the Phantom pump assembly in roughly three hours with an additional two hours to route and install the second (return) fuel line. So any of these system installations could be accomplished in a weekend. Ed Taylor helped us install a first-generation EZ-EFI in roughly 10 hours on our '65 El Camino, including the Phantom fuel system. We did cut a few corners on the ECU wiring that will need to be addressed, but you can use this as a guide.

The most important thing to remember when installing any of these EFI systems is to route the ECU 12-volt live power feed and ground directly to the battery or at the very least to separate terminals that are fed directly from the battery. A dual-terminal battery is perfect for this application.

The most important thing to remember when installing any of these EFI systems is to route the ECU 12-volt live power feed and ground directly to the battery or at the very least to separate terminals that are fed directly from the battery. A dual-terminal battery is perfect for this application.

Fuel Delivery

The underlying truth behind any EFI system is the fact that it will only be as good as the fuel-delivery system. So in order to be EFI successful, you must provide a qualified fuel-delivery system. There are several ways to approach fuel delivery, but based on our 25-plus years of experience with EFI systems, there's really only one way to go. We don't have the space to go into why a return-less system could work or the several reasons why an externally mounted pump is not the best idea for a typical muscle-car fuel system. Let's just cut to the chase and declare that if you really want your EFI-fed car to run properly in all conditions, do yourself a favor and follow our lead.

We've written perhaps a dozen stories over the years on fuel-delivery systems. Each of the four TBI manufacturers has its own fuel pump and delivery system because they have to give you that option. The key to a quality delivery system is an electric high-pressure pump that's capable of continuous fuel flow at 43- to 60-psi fuel pressure, do this with a minimum of noise, and finally to be robust enough to provide years of service with minimal maintenance. Any good fuel-delivery expert will tell you that this requires an inline, in-tank fuel pump. Inline pumps actually pump fuel through the inside of the pump around the spinning armature. This keeps the pump cool. Mounting the pump inside the fuel tank immerses it in fuel, which further enhances cooling. An in-tank pump uses the weight of the standing column of fuel to push it into the pump so it does not have to work to draw the fuel into the pump. External pumps must create a low-pressure area (which can cause vapor lock) when required to draw fuel vertically. Pumps are much better at pushing than pulling fuel. Externally mounting a pump in a muscle car usually then uses the stock fuel tank pickup. The problem here is that when the fuel level drops, fuel slosh during acceleration or cornering uncovers the pickup, fuel pressure drops, and the engine hesitates or bogs. This can work as long as you keep the fuel level above half full, but frankly, that's lame. There's a better way.

We've seen several ideas over the years for in-tank electric pumps and most of these are good systems, including the Rick's Tanks version we are using in our Nova. But, as in the Rick's Tanks case, it requires the use of a custom and sometimes stainless steel tank that can be expensive. In 2012, Steve Matusek, president and owner of Aeromotive, introduced the Phantom fuel-delivery system. This system uses a highly efficient turbine pump located on a stand that positions it just above the floor of your existing fuel tank and returns the fuel to the same location. The pump is surrounded by fuel cell foam with a small plastic bucket at the bottom that retains fuel around the pump. This is by far the most efficient, compact, and affordable fuel-delivery system idea we've ever seen. This is what you should use for a fuel-delivery system. Our recommendation is to purchase a basic TBI kit without the fuel-delivery system. Install the Phantom Aeromotive system and enjoy a trouble-free package.

An exception to this would be if you were going to max out the horsepower potential of the FAST EZ-EFI 2.0 at 1,200 hp. In that case, FAST offers a complete in-tank fuel pump kit (without a reservoir) under PN 307501 that FAST says will support as much as 1,900 naturally aspirated horsepower at 43 psi.

We've installed the Phantom system in a '65 El Camino in a previous story ("The Phantom Knows," Oct. '13) fitted with an EZ-EFI I TBI and tested the system by pushing the fuel level down to less than two gallons and experienced no surging or fuel-delivery hiccups. You should be able to sit on a hill with the engine idling with barely a couple of gallons of gas and not worry about the engine dying due to lack of fuel. That would be impossible with a stock tank using an external EFI pump because the fuel pickup would be sucking air. The Aeromotive Phantom system (PN 18688, $549.97, Summit Racing) is capable of delivering 340 liters per hour, equating to 90 gallons per hour, which Aeromotive conservatively rates at 825 EFI normally aspirated horsepower. This is more than enough fuel to feed any of the systems we've tested, except perhaps the EZ-EFI 2.0's at maximum horsepower potential. We'd also recommend a return-style regulator to complete the fuel-delivery system. We've built many EFI systems over the years and evaluated many others. The Phantom is the best EFI fuel-delivery system for a muscle car that we've ever seen. If you don't have the money to spend on a good fuel-delivery system, then you should ask yourself why you are spending $2,000 on EFI only to cheap out on the most critical component in the entire system. There's a reason that the OE companies all use in-tank fuel pumps for their cars. You should, too.

This is the heart of the Aeromotive Phantom system. The Stealth 340 pump hardly looks capable, but it can feed more than 800 EFI horsepower. The fuel is returned to this system and contained inside yellow fuel cell foam that is already inside the tank.

This is the heart of the Aeromotive Phantom system. The Stealth 340 pump hardly looks capable, but it can feed more than 800 EFI horsepower. The fuel is returned to this system and contained inside yellow fuel cell foam that is already inside the tank.

Configuring the ECU

Each EFI system requires specific inputs to configure the ECU to your particular application. These processes are usually called Calibration Wizard or Setup Wizard. The process follows a similar path—just not in this exact order. The first input is generally engine displacement. In our case, we input 496 ci. All but the EZ-EFI 2.0 also want a camshaft input. Some are more specific than others, but most rank the cam based on intake lobe duration numbers generally in categories of Stock, Mild, or Race. The Atomic system actually warns in the instructions that if the camshaft is more than 250 degrees of duration at 0.050, you shouldn't use this system. This is because intake manifold vacuum will be so low that the system would have difficulty working within those parameters. This is one reason why we chose to test these systems on our 496ci Nova, since our idle vacuum barely achieves 8 inches, which tends to tax the software design, as opposed to installing this system on a 350ci small-block with a mild cam that idles at 16 inches of manifold vacuum. After the camshaft, idle target rpm is another common input. This is essentially commanded idle speed. Keep in mind that if the IAC count on any of these systems is very low yet the engine speed is still too high, you may have to mechanically adjust the idle speed on the throttle body.

Rev limit is generally the next input these systems require. Because ignition control might not always be available, the systems use fuel shutoff to control engine speed. Keep in mind that this does not control mechanical engine over-speeds such as downshifting from Third to First at high speed. Some systems may also ask you the type of ignition you are using—either stock or capacitive discharge.

Other commands that you will need to set include the desired idle, cruise, and wide-open throttle (WOT) AFRs. We set our big-block up to idle at 13.9:1 with a similar air/fuel for cruise and a WOT AFR of 12.8:1. With these simple few inputs into the system, we were ready to rumble. If it sounds simple, it's only because it is.

Don’t overlook the charging system when considering EFI. While a typical ECU and injectors pull much less than 10 amps, add an electric fuel pump, a pair or electric fans, headlights, and possibly a heater or A/C blower fan, and all that could easily draw a minimum of 75 to 80 amps. This means to maintain system voltage at 14 volts you will need a charging system capable of at least 100 amps.

Don’t overlook the charging system when considering EFI. While a typical ECU and injectors pull much less than 10 amps, add an electric fuel pump, a pair or electric fans, headlights, and possibly a heater or A/C blower fan, and all that could easily draw a minimum of 75 to 80 amps. This means to maintain system voltage at 14 volts you will need a charging system capable of at least 100 amps.

Self-Tuning

The key feature of all these systems is what is called Self-Tuning. Let's use the commanded idle air/fuel ratio and idle speed as an example. To start, you command the speed you want the engine to idle and the AFR you want. Given the size of the engine, the injector size, the fuel pressure, the manifold pressure, and about a dozen other variables, the ECU estimates the amount of fuel required to deliver on those commands. The key is the feedback supplied by the WBO2 sensor. The oxygen sensor reports its readings to the ECU. The report will be that the AFR is either too lean, right on the money, or too rich. The ECU quickly computes the difference between commanded and actual and sends a new injector pulse width, and the process starts all over again. This is called closed-loop control. It only takes a short time for the ECU to narrow down the parameters, which is why it didn't take long for each of these systems to learn the basics necessary to make the engine run really well.

The critical point here is that by the stroke of a few keys you can create a system that runs exactly as you commanded. This kind of tuning requires days with a carburetor or hours with older EFI systems. All of this is predicated on the performance of the oxygen sensor, but the technology involved with wideband oxygen sensors has improved so much in the past few years that this kind of dependable performance is possible and all without having to earn a degree in computer science.

System Overview

It appears that the Holley throttle body is the only one that incorporates the linkage levers to accommodate the Ford C4 or C6 automatics.

It appears that the Holley throttle body is the only one that incorporates the linkage levers to accommodate the Ford C4 or C6 automatics.

Connections

Each of these closed-loop EFI systems operates in a similar manner. The ECU measures the critical engine parameters and creates a fuel-delivery schedule based on the inputs from the sensors. Most of these sensors are located on the throttle body itself, making the connections easy since they can only be attached to their intended sensor. So you can't screw up. The following are definitions for each sensor so you can see how each measures a certain engine function.

MAP (Manifold Absolute Pressure): Each of these EFI systems operate under Speed Density. This system assumes a certain level of volumetric efficiency based on displacement and creates a base fuel map that then establishes the amount of fuel delivered to the engine, given by its position on the fuel map, which is based on rpm and load. The MAP sensor converts the manifold vacuum level into a zero-to-5-volt signal to the ECU so it knows how much load the engine is currently experiencing.

TPS (Throttle Position Sensor): This simple device is much like a rheostat that converts the motion of the throttle into a zero-to-5-volt signal that tells the ECU how far the throttle is opened.

IAT/MAT (Inlet Air Temperature/Manifold Air Temperature): This sensor converts the inlet air temperature into a zero-to-5-volt scale, which helps the ECU to decide whether to richen the mixture when the air temperature is cold or make it lean when the air is hot.

CTS (Coolant Temperature Sensor): This converts engine temperature into a scale that the ECU uses to trim mixture.

IAC (Idle Air Control): This is actually a stepper motor controlled by the ECU that is used to maintain idle speed. When the engine is idling, generally a small amount of air is bypassed around the throttle blades through the IAC to maintain the commanded engine idle speed.

FPS (Fuel Pressure Sensor): All these systems use an FPS to monitor fuel pressure because this is critical to flowing sufficient fuel through the injectors. All of these systems are designed to operate between 43 and 60 psi.

RPM (Revolutions Per Minute): This is a critical input into the ECU since all the fuel and driveability programs are based on engine speed. Systems like the EZ-EFI 2.0 require a signal conditioner to establish a good signal to the ECU when using an HEI distributor.

WBO2 (Wideband O2): The wideband oxygen sensor is the critical feedback sensor used to help each self-learning system to adapt to the individual requirements of each different engine. The sensor actually measures the amount of free oxygen in the exhaust and calculates an air/fuel ratio from that measurement. This is why it's critical to seal any leaks in the exhaust system to minimize inaccurate (lean) O2 readings.

Fuel Mileage

Our fuel mileage test constituted the same, mostly highway, 105-mile loop that included one 15-minute stop to test for heat soak starting and roughly a dozen stop lights. To make the mileage test fair to the carburetor, we spent an afternoon (hours longer than it took to configure any of the EFI systems) tuning the Holley until we could get roughly a 13.9:1 air/fuel ratio at our 65-mph cruise speed. Had our test involved much more stop-and-go driving, the carburetor mileage would have suffered dramatically. As a side note, getting 14 mpg out of a near-600hp 496ci is pretty damn good. The 4L80E overdrive with the TCI lockup converter was a major factor. Our highway mileage rpm hovered around 2,300 rpm, and we commanded 13.9:1 air/fuel ratio for all four tests. We didn't try a leaner air/fuel ratio, but it's possible that we might have been able to wrestle even better mileage with a leaner AFR.

MSD Atomic Edelbrock E-Street Holley Terminator FAST EZ-EFI 2.0 Holley 950 HP carb 14.4 mpg 14.2 mpg 14.2 mpg 14.5 mpg 14.2 mpgHolley Terminator

So what makes the Terminator a possible best buy? What intrigued us was the ability to upgrade. Holley doesn't make a big deal of this, but the Terminator ECU is exactly the same as the one you buy for the HP or Dominator systems. This means that everything the Dominator system offers can be achieved by upgrading from Terminator. This means you don't have to sell your Terminator system if you later decide to add multi-point EFI or go to a multi-stage nitrous system. You do have to purchase additional wiring harnesses, but all the software is already there. Did you know that you can even control a 4L60E or 4L80E electronic overdrive transmission with the Dominator? If expandability is important to you, the Holley offers loads of potential.

Within the areas a handheld unit will give you access, Terminator offers plenty of additional tuning abilities. Under the Advanced Tuning category, you have multiple area access. We didn't have to go into them to allow our engine to run properly since the stock tune was very good, but it's comforting to know that the access is there should you want to perform a little fine-tuning. One example is that the rpm activation of closed loop is set to zero, which means the Terminator runs in continuous closed loop. But the system does offer the ability to increase the rpm to perhaps 1,500 to compensate for big overlap camshafts. The problem with big cams is that free oxygen from valve overlap enters the exhaust system and fools the WBO2 sensor into thinking the engine is running lean. Removing the closed-loop idle fuel control would allow you to manually tune the idle AFR to improve idle quality.

The basic Terminator kit includes the throttle body, ECU, and a compact handheld unit that is used to make the necessary inputs for your engine. Holley offers a basic polished TBI or the optional Hard Core Gray finish shown here. The color display is optional.

The basic Terminator kit includes the throttle body, ECU, and a compact handheld unit that is used to make the necessary inputs for your engine. Holley offers a basic polished TBI or the optional Hard Core Gray finish shown here. The color display is optional.

Another area where we found a significant difference was on the working end of the throttle body below the blades. Holley introduces fuel into the engine both from the large discharge hole directly below the injectors but also from several small holes drilled into the circumference of each throttle bore. The idea is to introduce fuel from multiple locations, especially at low throttle openings to enhance driveability.

Terminator also offers ignition control, should you want to integrate digital ignition control with the fuel. This offers advantages such as digital control over the timing curve that allows you to create a more specific timing map based on load and rpm. One way to simplify this conversion on a small- or big-block Chevy is to use the small-cap HEI-type distributor. The advantage here is these distributors are inexpensive and easy to find either used or new. On the Ford side, the system allows you to use a Ford TFI distributor. For our test, we retained our current MSD ignition system on the big-block so that the ignition remained the same for each TBI test.

Atomic EFI

Atomic is one of the latest iterations of the integrated throttle body fuel injection. The Atomic can accommodate any engine from 100 to 800 ci, with its only limitation being the injector output, which is limited to around 650 hp. This means that at 43 psi of fuel pressure the Atomic could easily supply fuel to a small 215ci Olds all-aluminum V8 as well as a monster 500ci Cadillac. Just as we were finishing this story, MSD announced an upgrade that now makes the Atomic compatible with both nitrous- and boost-ready supercharger packages. At press time, we didn't have any details on what makes the system boost-ready. The key with any claim is to look at the fuel flow potential of the injectors and compare them with the fuel required for your application.

As you might imagine, the Atomic will certainly allow ignition control if you so choose. A big advantage would be eliminating the archaic factory mechanical and vacuum advance mechanisms to allow non-linear tuning capabilities. If nothing else, you can do in a few keystrokes what used to take all afternoon to configure mechanical and vacuum advance curves. We did not integrate the ignition in our test, but it's reasonable to expect that we probably could have improved our fuel mileage by experimenting with the digital ignition curves, especially on the vacuum advance side.

The Atomic performed admirably feeding our 496ci, 590hp Rat. The driveability was excellent, and the fuel mileage was right there with the other systems, making this newest system an equal player among the four.

Edelbrock E-Street

When each of the TBI systems delivers similar benefits, it can often be the little things that can set one system apart. The Edelbrock E-Street's most notable feature is a large, 7-inch touch-screen Android tablet that offers Bluetooth wireless connection to the ECU. The tablet is not just essential for the initial setup but can also be configured as a gauge display. The wireless feature is attractive because it eliminates unsightly wires and allows user freedom to use the tablet apart from the vehicle. Plus, the tablet includes an antenna that allows it to be GPS-enabled by downloading software that will display vehicle speed. Even better, it also has Internet connectivity (Wi-Fi) for other tablet uses that have nothing to do with EFI. You might even consider permanently mounting the tablet in the dash. One small point was that our Android's battery life was shorter than anticipated.

If the number of pages in the instruction sheet is any indication, Edelbrock might be among the easiest to install since the EFI portion of the instruction manual is only 23 pages long. There is another 17 pages for the tablet, but even that only totals 40 pages. We configured the E-Street system in short order, and it quickly allowed us to start the engine and the big-block settled very quickly into an orderly idle. Our big camshaft (with 8 inches of manifold vacuum in gear) was no problem, and with our 4L80E in Overdrive, the E-Street delivered excellent light-throttle response, and quick stabs on the throttle to WOT were met with instant response. Overall, the only problem we encountered was in the cold-start test. For our 496ci engine, the E-Street delivered way too much fuel, requiring us to keep the engine running at 2,000-plus rpm for the first 45 seconds of operation before the engine began idling on its own. The problem was an over-rich, cold-engine enrichment program that unfortunately is not user-adjustable. Since the E-Street was the last of the self-learning systems to appear on the market, it's possible that feedback to Edelbrock from our experience will result in a software upgrade in the near future that will address this issue.

EZ-EFI 2.0

The most overwhelming fact about the EZ-EFI 2.0 system is its larger capacity. FAST has rated this throttle body with fuel flow potential to feed 1,200 hp. This is accomplished by including eight injectors compared to only four in the other systems. So if your engine has the potential to make 850 hp or more, the EZ-EFI 2.0 can handle it. Our first question concerned using this same monster TBI on a really tiny engine, such as a 4.8L (293ci) LS GM engine, for example. Controlling eight, 74-lb/hr injectors at idle on a small engine demands extremely short duty cycles that will cause control issues. FAST compensates by staging the injectors to fire only four at a time, which solves the dilemma. The advantage of these larger capacity injectors is that even at 850 hp the system is operating at a very comfortable injector duty cycle. So if big power is in your future, the EZ-EFI 2.0 can handle it.

While technically a different system, FAST also offers a separate kit called a multi-point upgrade that allows the use of the EZ-EFI 2.0 ECU with a multi-point fuel-injection system. So if we had an intake manifold with an injector in every port and a large throttle body upstream, we could control it all with self-learning EFI just like the TBI system. The advantage is the retrofit system is much less expensive than the TBI system (PN 30404-KIT).

Our experience with the EZ-EFI 2.0 was extremely positive. It did everything we asked it to do every time, and with its massive fuel potential, it's capable of even feeding a high-horsepower E85-fueled engine. If we had more time, we would have really liked to test this option.

Professional Products Powerjection III

We originally intended to test the Powerjection III unit because it also is a self-learning EFI throttle-body system. But that was until we opened the box and began reading the instructions. One of our criteria for this test was the fact that you could load the entire system on the car without the need for a laptop. Unfortunately, the Powerjection III requires a laptop to load the software into the computer, which it then imparts to the ECU that is integrated into the throttle body. From reading the instructions, we were going to have to make several critical changes to the base fuel program in order to create a usable package for our big-block Rat motor, since the software was designed for a 350ci engine. This complexity and the requirement for a laptop computer led us to not attempt to test the Powerjection III. It does appear to offer all of the basic amenities of the other systems, and it is also about $400 less expensive than the least expensive of our test systems.

The Powerjection III features a 750-cfm throttle body and four low impedance injectors flowing 62 lb/hr that should be capable of feeding more than 500 hp at 60 psi of fuel pressure. It is also capable of controlling ignition as well as fuel.

The Powerjection III features a 750-cfm throttle body and four low impedance injectors flowing 62 lb/hr that should be capable of feeding more than 500 hp at 60 psi of fuel pressure. It is also capable of controlling ignition as well as fuel.

Cold Start

Here's the only area where we discovered minor difficulties with a couple of the systems. Since this is more of a subjective evaluation, we decided to grade the systems on a 1-to-10 scale with 10 being best. Because we don't have access to a freeze room and we live near the ocean, our so-called cold-start is questionable since the coldest temperatures were in the mid-50 degrees F. With each system, we merely turned the ignition on to cycle the fuel pump, waited a few seconds and then tried to start our big 496.

A couple items are worth discussing. It's entirely possible that colder temperatures would produce different results. Unfortunately, cold-start is not a tuning function in some of the systems, although the EZ-EFI 2.0 offers access and the Holley at least gets you in under the "after start enrichment" category. If we hook a laptop up to the Terminator (which you can do after upgrading the software), the Holley instructions do give a simple procedure for tuning the cold-start, which is welcome.

The EZ-EFI 2.0 performed the best with a subjective score of 9 out of 10. This did require us to wait the two seconds necessary to allow the ECU to command the prime circuit, and you can actually hear the injectors cycling. If you encounter a problem, the EZ-EFI 2.0 allows you to modify the cold-start parameters, which is an improvement over the original version that was not user-adjustable. The Holley system does not require you to wait on startup and quickly settled into a stable idle. When we revved the engine once, it stalled on idle recovery, but immediately re-started without hesitation. We gave the Terminator an 8 rating.

The Atomic on cold-start was nearly as good as the other two with a stable idle and no hesitations on acceleration and no stalling. We gave it an 8 only because it was slightly richer than we would prefer. The Edelbrock cold-start test was problematic in that while the engine started easily, we had to manually maintain a 2,000-rpm engine speed to keep the engine running. Once the engine built some heat, the idle stabilized, and everything was fine. The reason for this was because our WBO2 sensor indicated a very rich mixture around 10:1 AFR. In speaking with the people at Edelbrock, they are aware of the problem and offered to alter our software to compensate. Because of this, we gave it a 6 for just the cold-start section. We expect that by the time you read this, Edelbrock engineers will have improved the cold-start program to minimize the excessively rich AFR.

HP Claims

In all these systems, the power limitations are not based on airflow but rather restrained by fuel flow of only four injectors. This is probably why FAST decided to up its game with the EZ-EFI 2.0 by doubling the injector count to eight injectors. FAST could have made the injectors smaller but instead sized them at 74 lb/hr. We decided to do the math on all these systems to see how the hp claims compare to the formula. The basic formula is:

Injector size x 0.85 (85 percent duty cycle) / 0.50 BSFC = hp per injector

There are several variables in this formula that require explanation. First is the duty cycle; this industry standard is intended to avoid running an injector at more than 85 percent of the time to improve injector life. A 100 percent duty cycle means the injector is open all the time, which leads to overheating and eventual failure. The second variable is the brake-specific fuel consumption (BSFC) number. This represents the number of pounds of fuel the engine burns (at WOT) per horsepower per hour. The industry standard is 0.50 lb/hp-hr. We've seen many dyno tests with engines now performing in the 0.45 and even 0.40 range at peak torque. These lower BSFC numbers are typical of today's current crop of Ford Mod, GM LS, and Chrysler Hemi engines that burn less fuel to make the same horsepower compared to older engines.

Another variable affecting injector output is fuel pressure. Any injector rating in lb/hr must include fuel pressure for accuracy. Most aftermarket injectors are rated at the industry standard 43 psi (3 bar). An easy way to increase injector output is to increase the fuel pressure from 43 psi to 60 psi. This can improve injector output by 18 percent. We will give you both the manufacturers' numbers and our calculated numbers.

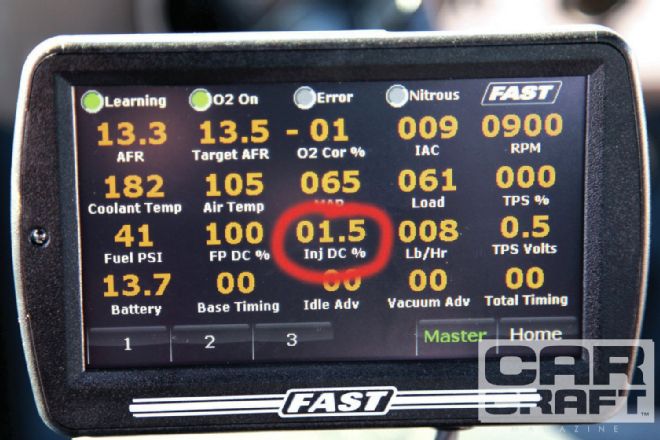

Among the many features of FAST’s EZ-EFI 2.0 is indicated injector duty cycle. In this photo, the engine is idling, so the injectors are working at 1.5 percent of their capacity. Next to this display is fuel pump (FP) duty cycle, and you can see that the pump is running at full capacity: 100 percent with regulated fuel pressure at 41 psi.

Among the many features of FAST’s EZ-EFI 2.0 is indicated injector duty cycle. In this photo, the engine is idling, so the injectors are working at 1.5 percent of their capacity. Next to this display is fuel pump (FP) duty cycle, and you can see that the pump is running at full capacity: 100 percent with regulated fuel pressure at 41 psi.

It's important to note that because every engine is different, your BSFC numbers might be better or worse than our estimates. That's one reason why having access to injector duty cycle numbers on the ECU's display is important. For example, if you have an engine that actually does make 550 hp and you command a 12.5:1 AFR at WOT, you can run the engine up to max power rpm and have a friend watch the injector duty cycle on the output screen. If at any point the ECU indicates more than 90 percent duty cycle, you know that your engine needs more fuel to supply the commanded AFR. This does not necessarily mean the engine is running too lean. Experimenting with different AFRs will show if the engine wants more or less fuel. This is why having another tuning aid like injector duty cycle is helpful.

We must also point out that just because some of these systems may not necessarily supply 600 hp worth of fuel at 43 psi doesn't mean they don't perform. Frankly, most of these EFI systems will find their way onto engines making less than 500 hp, in which case all these systems have more than enough injector "head room" to accommodate normally aspirated performance upgrades like better heads or a bigger camshaft.

Nitrous

In the early TBI self-learning systems, no one offered the opportunity to run a nitrous system. With these latest versions, a couple of systems are now compatible. Among the four systems, MSD, FAST, and Holley offer nitrous configurations. The EZ-EFI 2.0 system will work with the classic "wet" nitrous plate–type system, where both nitrous and fuel are introduced into the intake manifold. There is a Nitrous Setup category you can click on that allows you to select the target AFR, as well as a target total timing number. But the nitrous target timing number (effectively a nitrous retard) only works if the ignition is integrated with the EFI package. Otherwise, you will need to trigger a separate nitrous retard.

The advantage of using closed-loop feedback AFR control is that if the additional fuel supplied by the nitrous plate is slightly rich, the WBO2 will indicate this situation and the ECU will immediately respond to meet that commanded AFR. This has the potential to produce a measurable advantage over a straight carbureted nitrous application. This is basically how the Holley system is also intended to be used, but you will have to perform the free upgrade to the HP version of the software, and this will require a laptop. But it's easy—just buy your laptop buddy lunch.

Software Upgrades

When it comes to electronics, we have come to expect that after the device goes out the door, there will be upgrades. The same is true with EFI systems. The ease with which you can do this will depend upon which system you are working with. One thing to keep in mind is that if you do upgrade, any specific changes you made the existing software will be lost, so it's best to track the changes you've made in a written record that will make it easier to input them back into the ECU once the upgrade is complete.

As an example, because the Edelbrock system uses the Android tablet, software improvements might be a little easier since you can quickly access the upgrade off the Internet and then load it to the ECU. We watched a short video by MSD that showed how to upgrade the software, which involves removing the micro-SD card from the ECU, purchasing an SD card reader, and then accessing the new software from Atomic's website to upgrade the card using the reader. The Terminator system is designed so that a laptop is not needed. However, if you desire to go into the system to make changes that are not currently allowed, Holley engineer Doug Flynn told us that with a laptop and an inexpensive USB cable you can download the Holley V2 software into your laptop and then use that to upgrade the Terminator system. The EZ-EFI system also accommodates updates via the Internet. In all cases, should the manufacturer come up with software improvements, all it takes is a relatively simple upgrade to bring your older system up to date. That's the beauty of electronics.

Throttle Body Horsepower Potential

Parts List

Just as this story went to press, we learned that Quick Fuel Technology has introduced its own bolt-on TBI, self-learning EFI system called QFI. The throttle body will be capable of delivering 500 hp worth of fuel from four 62 lb/hr injectors with a patent-pending annular discharge fuel delivery technique. The QFI will also offer onboard full ignition timing control along with a two-step rev limiter. End

Just as this story went to press, we learned that Quick Fuel Technology has introduced its own bolt-on TBI, self-learning EFI system called QFI. The throttle body will be capable of delivering 500 hp worth of fuel from four 62 lb/hr injectors with a patent-pending annular discharge fuel delivery technique. The QFI will also offer onboard full ignition timing control along with a two-step rev limiter. End