Photography Courtesy of SMI

When you think about it, it's kind of funny that motor racing is one of the last places you will find a two-barrel carburetor. Meanwhile, you will have to look pretty long and hard to find a race car driver who actually loves racing a two-barrel.

Honestly, the only reason you will find a two-barrel carburetor on a race car is because the rule book requires it. A four-barrel carb is almost universally better at providing the right combination of good throttle response on the track while also providing plenty of air to the engine for power. Two-barrel carburetors are still around in racing mostly because sanctioning bodies continue to use them as a restrictor plate of sorts. By requiring a two-barrel on a Late Model Stock V-8 or some similar class, the carburetor limits the amount of air the engine can ingest, which in turn, limits the horsepower it can make.

So obviously, any legal improvements you can make to the carburetor will result in significant power gains. The same goes for making sure your two-barrel is properly tuned. And there is plenty that can be done to make a Holley two-barrel flow more air more efficiency than it ever could in stock form. By the way, although a 500-cfm two-barrel normally used with Mini Stock race cars running four-cylinder engines (mostly Ford's 2,300cc from Mustangs, Pintos, and Ranger pickups) can provide about all the air and fuel these four-bangers can handle, winning performance is also dependent upon proper carb tuning.

An entire industry has sprung up around building and tuning two-barrel carburetors for racing, and while many of these carb specialists can work miracles with a two-barrel it doesn't mean that you have to depend on them for everything. There is actually a lot you can do yourself to help improve a two-barrel carb. And if you are trying to race on a limited budget or build a Mini Stock as your son or daughter's first race car, you may not need a high-end, professionally built carburetor. Instead, doing a little tuning work yourself can significantly improve your performance over stock without costing you much at all.

With that in mind, we turned to Sean Murphy of Sean Murphy Induction, one of the most successful carb building and tuning shops in the nation. We've worked with Sean and SMI in previous issues of Circle Track on racing Rochester/Quadrajet carburetors and were greatly impressed both with the depth of Sean's knowledge and his willingness to share it. (If you want to see those previous two articles, just go to www.circletrack.com and type "Rochester" or "Sean Murphy" in the search box. You'll be glad you did.) So obviously, when we wanted to learn more about building and tuning the venerable Holley two-barrel, we went back to Murphy and he practically buried us under an avalanche of great information.

The following is just some of what SMI gets into when it preps a Holley two-barrel carb. This definitely isn't everything they do, but it should be enough for anyone to improve their own racing program by ensuring their two-barrel carb is properly prepared for the task at hand.

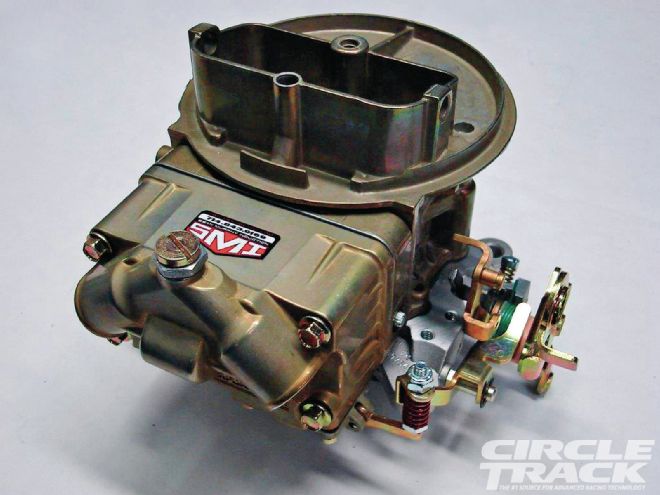

It may look a lot like your standard Holley two-barrel carburetor on the outside, but this carb has been through the works thanks to Sean Murphy Induction (SMI). And while it is still legal for almost all racing classes, it’s performance on the racetrack should be able to far outpace any box-stock carb.

It may look a lot like your standard Holley two-barrel carburetor on the outside, but this carb has been through the works thanks to Sean Murphy Induction (SMI). And while it is still legal for almost all racing classes, it’s performance on the racetrack should be able to far outpace any box-stock carb.

We went back to Murphy and he practically buried us under an avalanche of great information

[1] Unlike many carb specialists that rarely get any farther than a flow bench, SMI performs significant testing on its carburetors in real-world situations. SMI's Sean Murphy says the Holley 4412 was originally designed for the Ford FE big-block typically installed on 3/4 and one-ton trucks. So you can see why it is quite out of its element on a high-revving race car. Still, SMI has been able to make more than 530 hp with these carburetors.

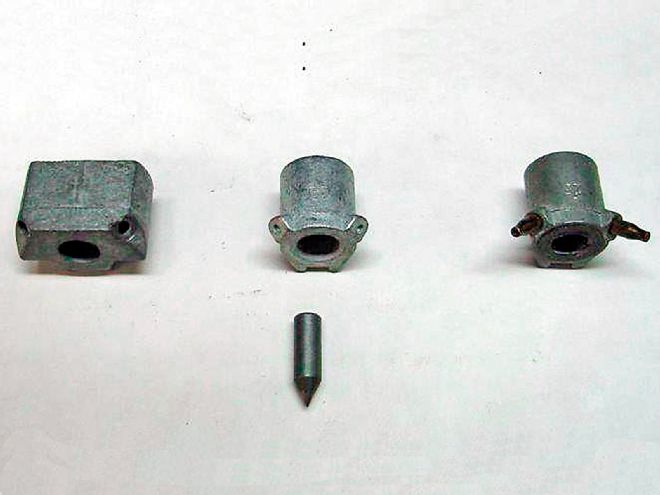

[2] One of the keys to properly tuning any carburetor is getting the metering block right. Not all metering blocks will work in every situation. As an example, SMI provided this photo of three different metering blocks. The top block is a billet aluminum unit designed to work in racing applications burning alcohol. The middle block is a stock unit, and the bottom is the improved metering block from an HP carb.

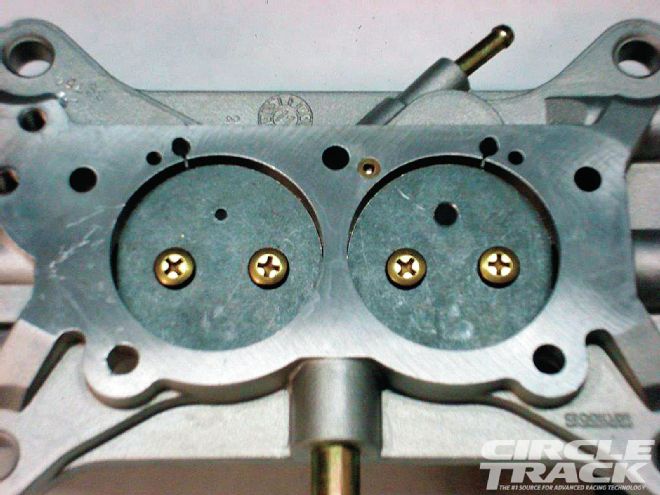

[3] A circle track racing carburetor must perform well at idle, full throttle and everywhere in between. It doesn't matter how much peak power the carburetor makes if it causes the engine to stumble every time the driver gets on the throttle coming out of a turn. This photo shows the butterflies with a stock hole in the left plate and a larger hole SMI has drilled through the right plate. The larger hole allows more air to bypass at idle, which is needed by a larger-than-stock racing cam. This keeps the throttle plate at the correct angle (closed) while still providing enough airflow through the hole to keep the engine idling at the correct rpm.

[4] At the top is a stock 50cc accelerator pump. Below that is a 30cc pump. The larger 50cc pump is undesirable in all cases with the exception of alcohol carbs and some low rpm four-cylinder engines. On a V-8 race engine the 50cc accelerator pump will cause an overly rich condition when introducing throttle off the corner. This will result in the car feeling lazy. The reason is because the airspeed is too high due to the carb being undersized for the application (going back to that whole restrictor plate thing). Therefore, the main fuel circuit, or booster, is almost always active and delivering fuel. So it is unnecessary for the accelerator pump to deliver the same amount of additional fuel that would be needed with a properly sized carburetor.

[5] That's a stock float on the left and a tapered float on the right. As the car enters the corner, g-forces push the fuel in the float bowl to the right side, which picks up that float. When the float moves up it closes the needle and seat, cutting off fuel delivery while the car is in the corner. When the g-forces are sustained like in a long corner, this can create a situation where the fuel level in the bowl is too low when the car exits the corner and the driver opens up the throttle. A lean stumble can occur as the fuel system attempts to "catch up" and fill the bowl once again. The tapered float can help keep this from happening by not allowing fuel slosh to get under it and push it up if the fuel bowl isn't actually full.

[6] A carburetor can run great, but if it gets you thrown out at the tech shed, it isn't much good to you. Because of this, Murphy says SMI goes to great lengths to make sure its carbs push the limits as far as possible without going over the line toward the dreaded "illegal." This is a go/no go step gauge they've created to make sure the carburetor venturiis are as large as possible while still being legal by the gauges used by your friendly neighborhood tech man. That ridge is pretty small.

[7] Here, you can see the gauge in an SMI carb. The venturi was opened up enough to allow the smaller portion of the gauge through, but the couple extra thousandths of an inch of thickness was enough to keep the big end from going through.

[8] These are the idle (left, notice the larger diameter) and high speed (right) air bleeds. These are important tools in tuning the fuel curve for different applications. The high speed is very influential on the curve at the top one-third to one-quarter of the rpm range. A change of a few thousandths of an inch of the diameter of the bleed can make a very large change in the air/fuel ratio.

[9] This is a shot of SMI's APS (anti pull-over system) kit. The custom kit replaces the regular weighted pin and accelerator pump discharge nozzle screw with a spring-loaded check ball. The idea is that the check ball helps maintain positive pressure to stop unwanted fuel discharge from the nozzle at high rpm levels. This happens to a lot of V-8 applications and almost every time on four-cylinder racing engines. The reason for this undesirable situation occurring on V-8 engines is because the extremely high air speed—far greater than what the carburetor was ever designed for—literally turns the discharge nozzle into a "booster." The pressure drop acting on it is great enough to pick the factory weighted pin up off its seat and draw fuel through the pump circuit. In four-cylinder applications the engine's harmonics (vibrations) "dances" the pin off the seat and the fuel right out of the nozzle—even at idle. Oddly, Murphy says that, in some cases, the condition calms down at higher rpm levels because the time between firing pulses is reduced and the engine becomes more "balanced."

[10] These are the three types of accelerator pump discharge nozzles. Starting from the left, that's an anti pull-over discharge nozzle, a standard, and a tube-type. Never use a tube-type as they increase the chance of pull-over. That happens because the tubes are placed further out of the air stream. The anti pull-over type of discharge nozzle is rarely effective and only applies to the extreme airflow situation created by the V-8 engine anyway.

[11] This photo shows the two power valve channel restrictors (PVCR), which are the two small holes on either side of the large hole in the center for the power valve. They work in conjunction with the main jets to provide fuel delivery to the main circuit. The power valve is a normally open valve that is controlled by the manifold pressure (vacuum). At idle and light throttle—such as when you are running around under caution—it is held closed because the throttle is partially closed creating vacuum in the plenum of the intake manifold. At full throttle the valve opens via spring pressure since the fully open throttle removes the restriction to airflow which gets rid of the vacuum condition in the intake. Except in V-8 applications running a two-barrel the carburetor is undersized and acts as a restrictor to the intake tract air flow. Therefore, at high rpm levels positive manifold pressure (vacuum) is created because the cylinders pull more air than the carburetor can provide, even at wide-open throttle. Think of it as trying to drink a milkshake through a cocktail straw. Your mouth is the manifold plenum and the straw is the carburetor. In many cases the vacuum created will be strong enough to overcome the power valve's spring and the valve will close. A good tuner will use this to their advantage. At high rpm the pressure drop (or signal) at the booster is far beyond anything that the carburetor was designed to handle thanks to the extreme volume and speed of the air travelling through the venturi. The result is excessive fuel delivery from the booster. To help control this situation a tuner will use the spring pressure of the power valve to determine the "timing" when the valve closes at high rpm to manipulate the fuel curve to keep the carburetor from going rich at high rpm levels. To get this right the PCVR size must also be considered, but in two ways—how much fuel it provides when it opens at low rpm, as well as how much fuel it takes away when it closes at high rpm.

[12] These are the emulsion holes. Think of them as holes in a garden hose, and the main circuit is the garden hose itself. The emulsion system works in conjunction with the high-speed air bleed to help mix oxygen and emulsify the fuel prior to being discharged from the carburetor. The emulsion holes also have an effect on when the main circuit activates and affects how pressure drop at the booster results in fuel delivery. As mentioned before, the emulsion holes have the same effect on the carb as you trying to such water through a hose that has holes in it. The larger the diameter of holes and the more holes you have, the harder it is to suck water through the hose. This can be helpful when tuning a carburetor that is undersized and sees a very high pressure drop across the venturi booster because of it.

[13] Although it's listed as a 500-cfm carb, the Holley 4412 is almost completely identical to the primary side of the Holley 4779, which is a 750-cfm mechanical secondary four-barrel carb—aka the "750 Double Pumper." This is because two- and four-barrel carburetors are tested differently.