At one time, the only power steering available on trucks was laughingly referred to as the “Armstrong” style. That meant that if your arms didn’t look like Popeye’s, cranking the wheel around could be tough because the driver was the only source of power steering. Today things are different, and thanks to steering swaps and rack-and-pinion conversions power steering is easy to add to most trucks. But while power steering swaps are common, so are complaints concerning steering sensitivity. The problem usually comes about from mixing and matching components or using pumps that “over-assist” the steering gear.

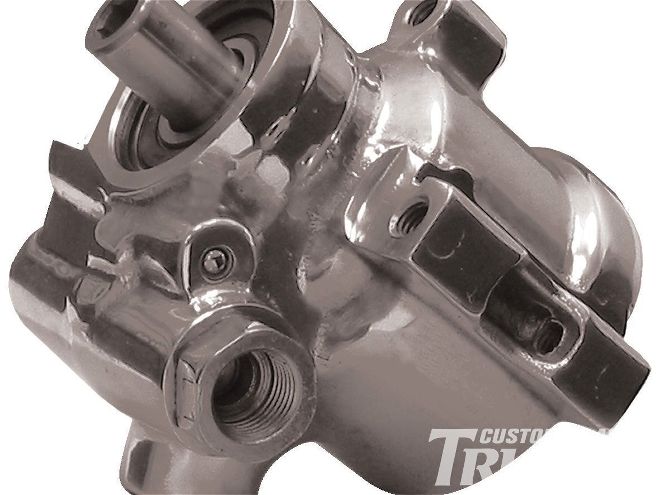

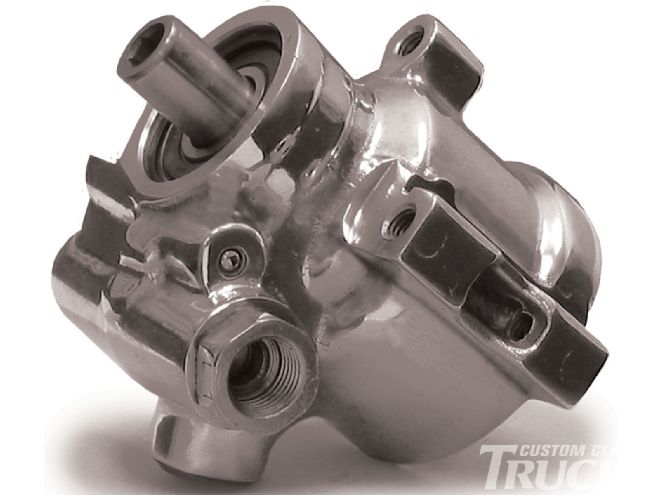

For a clean look and easy packaging, a popular choice is a GM Type II power steering pump that uses a remote reservoir. Borgeson offers them for V-belt or serpentine drives with pressure preset for Mustang rack-and-pinion or GM boxes. Pumps are available in polished or cast finish, with slip-on or AN connections.

For a clean look and easy packaging, a popular choice is a GM Type II power steering pump that uses a remote reservoir. Borgeson offers them for V-belt or serpentine drives with pressure preset for Mustang rack-and-pinion or GM boxes. Pumps are available in polished or cast finish, with slip-on or AN connections.

In most cases a Saginaw is the power steering pump of choice. As Jeff Grantmeyer at Borgeson explains it, the Saginaw self-contained power steering pump was used widely by all Big Three auto manufactures from the ’60’s on up into early 2000. Over the years there have been many different variations of this, but they fall into two general categories—the self-contained “canned ham” pump with an integral reservoir, and the Type II with a remote reservoir. About the only version that’s not commonly used is the “P-Series” pump found on early fullsize cars and Chevy/GMC medium-duty trucks.

Pump Basics

Pump pulley shaft: The Saginaw self-contained pump was offered with two different pulley shafts. The 5⁄8-inch nut retained keyway style shaft was used from its inception until 1974 and the ¾-inch diameter “press-on” style shaft used from 1975 and on.

Commonly called the “canned ham” style, Saginaw pumps with integral reservoirs come in a variety of configurations. Note the shape of the return line in the center of the reservoir.

Commonly called the “canned ham” style, Saginaw pumps with integral reservoirs come in a variety of configurations. Note the shape of the return line in the center of the reservoir.

Pressure hose connection: The Saginaw self-contained pump was offered with two different high-pressure hose fittings. The 5⁄8-inch flare connection was used from the beginning until 1979 and a 16mm O-ring connection was used from 1980 on.

Pump mounting studs/holes: The mounting studs/holes changed on the same timeline as the pressure fitting above from SAE to metric.

This pump has two returns, the second is for a Hydro-Boost brake system.

This pump has two returns, the second is for a Hydro-Boost brake system.

Pump reservoir: The Saginaw self-contained pump was offered with way too many hose-return-fitting configurations. The hose-return fitting varied completely by original vehicle application. Some reservoirs had returns running up, back, left, right, forward—well you get the idea. The Saginaw pump reservoirs were even offered with two return fittings for vehicles with a Hydro-Boost brake system.

Pump flow/valve rating: This is another aspect of the pump that varied completely by original application. The OEMs would specify what flow rating was required based on vehicle weight, steering gear piston diameter, and whether or not the pump was running a Hydro-Boost brake system. The Saginaw pump in OEM applications can be set from 2.0 on up to 4.5 gpm.

2 3 Saginaw pumps are not very complicated and relatively bullet proof. The rotor with sliding vanes (1) spins inside the housing (2) to produce pressure. The pressure relief valve assembly is on the right (3). 1

2 3 Saginaw pumps are not very complicated and relatively bullet proof. The rotor with sliding vanes (1) spins inside the housing (2) to produce pressure. The pressure relief valve assembly is on the right (3). 1

Pump bypass pressure: Just like the flow rating above, the OEMs would specify output pressure based on the original vehicle application and what system the pump was running. Most steering gear applications would run between 1,100-1,300 psi with heavy vehicle high-demand applications on up to 1,550-1,600 psi. Rack-and-pinion steering, on the other hand, is generally happier at a lower operating pressure of 850-950 psi.

Excessive response/touchy steering: This is generally caused by excessive pump pressure, Borgeson offers a pressure reduction kit (part number 899001) that will allow the customer to adjust the internal bypass pressure of the P/S pump (self-contained and Type II with a remote reservoir).

Power Steering Pump Troubleshooting Tips from Borgeson

Inoperable pump: There is usually one cause for a new P/S pump to be inoperable—damage during pulley installation. The pulley, although called press-on, is not to be pressed on—a pulley installation tool must be used. Failure to use the proper installation tool can crack the pump housing and cause the pump to be inoperable.

The pulley installation tool threads into the pump’s shaft; the nut is tightened to pull the pulley onto the shaft.

The pulley installation tool threads into the pump’s shaft; the nut is tightened to pull the pulley onto the shaft.

Pump noise or groan: This is most commonly caused by a restriction or air trapped in the system. Can also be caused by heat buildup. (This would include a loss of assist.)

To remove a press-on pulley, this dedicated puller is required. The split ring grabs the groove on the pulley snout, the solid ring holds the two pieces in position, and the screw pushes on the end of the shaft.

To remove a press-on pulley, this dedicated puller is required. The split ring grabs the groove on the pulley snout, the solid ring holds the two pieces in position, and the screw pushes on the end of the shaft.

No power assist after recent system service: This is most commonly caused by fluid contamination causing the pressure bypass valve to stick open resulting in no pump pressure. To fix this, remove the flow valve and ensure the pressure bypass valve moves freely in and out. This can also be caused by a large amount of air trapped in the system.

Hard steering in both directions: This can result from insufficient pump flow/pressure, low P/S fluid level, air trapped in system and excessive heat buildup.

Borgeson’s pressure-adjusting kit (part number 899001) includes a clamping tool, six shims, and installation instructions for lowering the bypass pressure on all GM self-contained and Type II power steering pumps.

Borgeson’s pressure-adjusting kit (part number 899001) includes a clamping tool, six shims, and installation instructions for lowering the bypass pressure on all GM self-contained and Type II power steering pumps.

Foamy P/S fluid: This is most often caused by either air trapped in the system or a leak in the return line sucking in air.

Reservoir cap blows off: This is most often caused by an air leak. Air is sucked into the P/S system compressed with the fluid and then expands when it reaches the reservoir causing an unintended pressure buildup in reservoir. CCT

To make adjustments, the pressure valve assembly is removed from the pump. It’s a part of the fitting where the high-pressure hose attaches.

To make adjustments, the pressure valve assembly is removed from the pump. It’s a part of the fitting where the high-pressure hose attaches.