With Project Pure Poncho fully broken-in and its power documented (491.8 hp/551 lb-ft), it was now time to begin our research and development work.

As a review to those who may not have followed the build-up, our test engine is a 467ci mill with ported 6X cylinder heads, a hydraulic roller camshaft, and a street-friendly 9.1:1 compression ratio. It was built by RaceKrafters Automotive Machine with components supplied by Summit Racing and Butler Performance. Its purpose is to test parts and combinations, along with engine theory so that when the time comes to modify your engine, real, hard data has been established.

After promising results from out first dyno testing and tuning in the last issue using 92-octane fuel, now our 467-ci Mule will reveal how it reacts to changes in fuel octane.

After promising results from out first dyno testing and tuning in the last issue using 92-octane fuel, now our 467-ci Mule will reveal how it reacts to changes in fuel octane.

Over time, the gamut of testing will be quite broad, so HPP felt the best place to start would be to determine the engine’s octane tolerance in its current form. There has been much written and discussed on all levels about the octane requirements of a Pontiac engine. Some is rooted in truth, while some is simply opinion. We will test for octane appetite using a quasi-scientific method.

Octane Demand

The Sept. ’11 issue of HPP features an in-depth primer about gasoline (“Give It the Gas”) so it’s a good idea to reference that before fully digesting our octane testing.

Octane by definition is not complex—it’s simply the fuel’s ability to withstand pressure and heat without reverting to auto ignition. The fuel needs to wait for the arcing of the spark plug to begin its burn and expansion across the bore. When this doesn’t occur and the fuel ignites independently of a spark, it’s referred to as abnormal combustion. When fuel waits for the arcing of the plug electrode, it’s called normal combustion.

Best Dyno Pulls

88-Octane Rockett Brand Fuel

RPM

TQ

HP

BSFC

3,300

545.3

342.6

0.37

3,400

548.7

355.2

0.36

3,500

551.0

367.2

0.37

3,600

551.0

377.7

0.37

3,700

550.1

387.5

0.38

3,800

549.2

397.3

0.37

3,900

543.7

403.7

0.37

4,000

544.0

414.3

0.37

4,100

547.0

427.0

0.36

4,200

546.4

437.0

0.36

4,300

545.0

446.2

0.36

4,400

543.9

455.6

0.36

4,500

537.2

460.3

0.37

4,600

535.1

468.6

0.37

4,700

531.1

475.3

0.38

4,800

526.0

480.7

0.39

4,900

519.8

485.0

0.39

5,000

508.6

484.2

0.40

5,100

503.1

488.6

0.41

5,200

491.7

486.8

0.41

5,300

482.0

486.4

0.42

#73/#73 jets, 32 degrees timing

94-Octane Rockett Brand Fuel

RPM

TQ

HP

BSFC

3,300

547.5

344.0

0.39

3,400

551.8

357.2

0.38

3,500

553.4

368.8

0.39

3,600

554.2

379.8

0.38

3,700

551.4

388.5

0.39

3,800

552.2

399.5

0.40

3,900

552.6

410.3

0.40

4,000

551.7

420.2

0.39

4,100

551.0

430.1

0.38

4,200

546.5

437.0

0.40

4,300

548.3

448.9

0.39

4,400

546.1

457.5

0.39

4,500

543.3

465.5

0.40

4,600

538.6

471.8

0.41

4,700

534.8

478.6

0.42

4,800

527.8

482.4

0.41

4,900

521.1

486.1

0.41

5,000

513.0

489.1

0.42

5,100

500.2

485.7

0.44

5,200

493.2

488.3

0.45

5,300

480.9

485.3

0.46

#79/#79 jets, 32-degrees timing The different chemical composition is the reason this fuel wanted more jet than the others.

100-Octane Rockett Brand fuel

RPM

TQ

HP

BSFC

3,300

544.2

341.9

0.39

3,400

548.7

355.2

0.39

3,500

552.0

367.9

0.39

3,600

550.8

377.5

0.40

3,700

550.7

387.9

0.40

3,800

548.0

396.5

0.40

3,900

549.0

407.7

0.39

4,000

549.0

418.1

0.39

4,100

546.9

426.9

0.39

4,200

550.8

440.5

0.38

4,300

549.0

449.5

0.38

4,400

546.4

457.8

0.38

4,500

543.4

465.6

0.39

4,600

541.2

474.0

0.39

4,700

534.9

478.7

0.40

4,800

530.4

484.8

0.41

4,900

525.3

490.1

0.42

5,000

516.6

491.8

0.41

5,100

507.4

492.7

0.41

5,200

498.0

493.0

0.44

5,300

488.3

492.7

0.46

#73/#73 jets, 34 degrees timing

The Rockett Brand 100 octane is considered a race fuel that is street legal. For this reason, the full specifications are supplied. Note that it had no ethanol and the oxygen content was slightly lower. The RON is 105 while the MON is 97, which would put the AKI at around 101 octane--an excellent fuel for race day with a street/strip Pontiac.

The Rockett Brand 100 octane is considered a race fuel that is street legal. For this reason, the full specifications are supplied. Note that it had no ethanol and the oxygen content was slightly lower. The RON is 105 while the MON is 97, which would put the AKI at around 101 octane--an excellent fuel for race day with a street/strip Pontiac.

Depending on the piston’s location when the auto ignition occurs, the abnormal event can be identified as pre- or post-ignition. As lay people, we refer to it as ping, knock, or detonation. In every instance, it’s detrimental to the engine, emissions output, and power. Any Pontiac that experiences abnormal combustion is not giving its all, and depending on the severity and timing of the rogue flame, may actually be self-destructing.

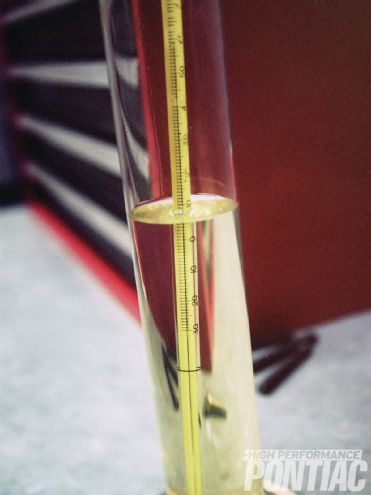

Kinsler offers a very complete fuel test kit to measure the weight of the fuel. It is a good tool for the serious racer.

Kinsler offers a very complete fuel test kit to measure the weight of the fuel. It is a good tool for the serious racer.

Applying octane’s definition, anything that raises the pressure or heat in the cylinder will test the fuel’s ability to not ignite until electrically induced. There are many factors that promote abnormal combustion, with a dominant one being the compression ratio. It is all too easy for any enthusiast to demonize the compression ratio as the only reason for abnormal combustion, but in reality, an engine is a synergistic approach that is the melding of many different events and design factors. To deem the compression ratio as the only reason for abnormal combustion would be as wrong as to identify a singular cause for a human disease. The end result may be the same, but the impetus for it can often be different.

Out of respect to those who want to tell me I am wrong about compression ratio and its impact on the combustion event, please keep in mind that HPP is not talking about extremes. Without a doubt, street gas will not support a 14:1 compression ratio—that is not what is being stated. We want to know if an iron-head street/strip Pontiac should be built with 9:1, 8.0:1, or a 10.0:1 compression ratio? These are all values that are often mentioned during bench racing sessions. To some, our engine at 9.1:1 is at the threshold of what they call streetable on pump gas. We’ll see.

The weight of the fuel is corrected to a standard of 60 degrees F

The weight of the fuel is corrected to a standard of 60 degrees F

It needs to be understood that the best running engines enjoy a compression ratio that is high enough to promote good thermal efficiency and throttle response, and be the most powerful without experiencing abnormal combustion. If you lower the compression ratio too much because you believe it’s needed to run on pump gas, then you may very well be giving away the attributes that a higher ratio delivers. If the compression ratio is too high then the Pontiac may not run on pump gas and is no longer really a street car. For this reason, we felt it would be of benefit to the entire community to find the sweet spot on the compression-ratio bell curve using our Mule as the testbed.

Let’s define the term pump gas. It’s street-legal gasoine that can be purchased by the public. Would any of you think of filling the tank of a nearly 500hp street Pontiac with 88-octane regular? Well, we didn’t fill the tank, but we did pour it into the fuel cell that fed our Mule on the dyno. For a hint of things to come—there are no burnt pistons. More on that later.

Though Rockett Brand Racing Fuel supplied specific gravity for each fuel, we confirmed the specification using a hydrometer.

Though Rockett Brand Racing Fuel supplied specific gravity for each fuel, we confirmed the specification using a hydrometer.

We planned to run regular, premium, and 100-octane street gasoline. We saw no value in mid-grade since we book-ended the octane of that fuel with regular and premium. We would dyno the engine with each fuel and make whatever necessary tuning changes required to optimize the combination, as was done with the 92-octane last issue. The same protocol that was established during the initial testing of confirming the results and tuning changes in each direction would be followed.

There was one problem that first needed to be solved. HPP required a source of fuel other than the local filling station. We needed the actual octane of each gasoline and its quality confirmed. This would not have been possible by going to a local gas station—the octane can be skewed from the pump value since by law that is the minimum octane the consumer is purchasing. So we turned to Rockett Brand Racing Fuel, the supplier of the gasoline for the two articles that ran in the Sept. ’11 issue.

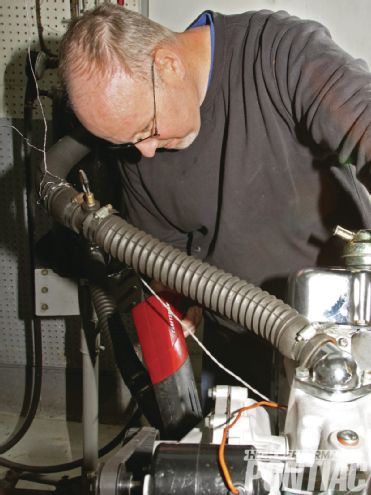

Bob Wise loads the dyno fuel cell with fresh Rockett Brand Racing Fuel. It's a process that would be repeated often throughout the day. Each time the fuel was changed, the system was purged to ensure that there was no residual fuel from the previous test remaining.

Bob Wise loads the dyno fuel cell with fresh Rockett Brand Racing Fuel. It's a process that would be repeated often throughout the day. Each time the fuel was changed, the system was purged to ensure that there was no residual fuel from the previous test remaining.

Rockett Brand Racing Fuel is a quality producer of race and street gasoline. The company offers a full line of products to the consumer, and its website offers a wealth of technical information that would be of value to any Pontiac driver. The staff at Rockett Brand Racing Fuel was willing to supply three different grades of gasoline and test them in their laboratory before shipment to RaceKrafters. They confirmed the octane and chemical composition for each blend, and supplied us with 88-, 94-, and 100-octane fuel. With the quality and octane of the fuel confirmed, we were able to move forward with our testing with full confidence that our data wouldn’t be corrupted.

There are a few caveats that need to be supplied, along with a brief review of some terms. Our Mule is a fresh engine; accordingly it doesn’t suffer from carbon in the cylinders or on the piston crowns, corrosion in the cooling system or oil leaking past the valve guide seals or piston rings. It was breathing intake air at the carburetor inlet of around 75 degrees. All of these factors worked to the benefit of minimizing the octane requirement of the Pontiac.

Craig manned the dyno controls for each pull. With the Depac data system and controls the testing was uniform to guarantee accurate results.

Craig manned the dyno controls for each pull. With the Depac data system and controls the testing was uniform to guarantee accurate results.

Though you cannot change the weather, you can keep the combustion chambers and pistons free of carbon deposits, the engine in good mechanical condition, and the cooling system working properly. Thus, our test will be valid for the majority of driving and operating scenarios that a well-maintained Pontiac may see.

In extremely hot weather, the engine’s desire for octane may in theory increase. So if you live in a climate that has huge swings in temperature and is normally around 100 degrees F in the summer, you may need to alter the fuel you use during that time of year. But for the majority of the country, that is not the case. A good rule is that as ambient temperature increases, so does octane demand; as altitude decreases, so does octane demand. A cold, high place would require the least amount of octane in any engine to ward off abnormal combustion.

Important terms are octane tolerance and octane creep.

Craig checks the timing after an adjustment.

Craig checks the timing after an adjustment.

Octane tolerance is the minimum amount of octane required to support normal combustion. It’s usually defined by an SAE standard test protocol. Since the protocol varies, the best thing for the enthusiast to do is to use the driving conditions their Pontiac experiences as the threshold for octane tolerance. There is no use worrying about conditions the car may never see. The facts should be based on your real world and not some engineering standard.

FuelOctaneSpecific GravityOxygen Content By WeightEthanol Content By Volume Local Sourced920.748N/AN/A Rockett Brand880.7273.9%10.5% Rockett Brand940.7134%10.8% Rockett Brand1000.7173.5%NoneOctane creep defines the increase in octane that is required as the engine builds carbon deposits. For example, a fresh or new engine in any car may only require 87-octane to support normal combustion, but as mileage accumulates along with carbon deposits, the octane needs to be ramped up or abnormal combustion will occur. There are all different theories on the rate of creep. In the author’s opinion, there are too many variables to define an actual mileage when creep will increase the octane demand. Some are the engine design, fuel used, driving style, service intervals, and operating conditions. That brings me back to proper maintenance and care. A proper tune and use of fuel, along with additives that not only limit carbon buildup but remove it, will keep creep at bay over the life of the vehicle. A driving style that minimizes engine idling and short-cycle trips goes a long way to hinder creep.

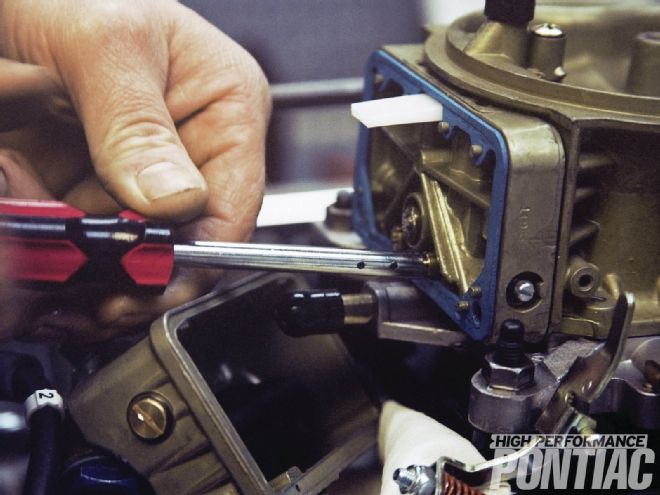

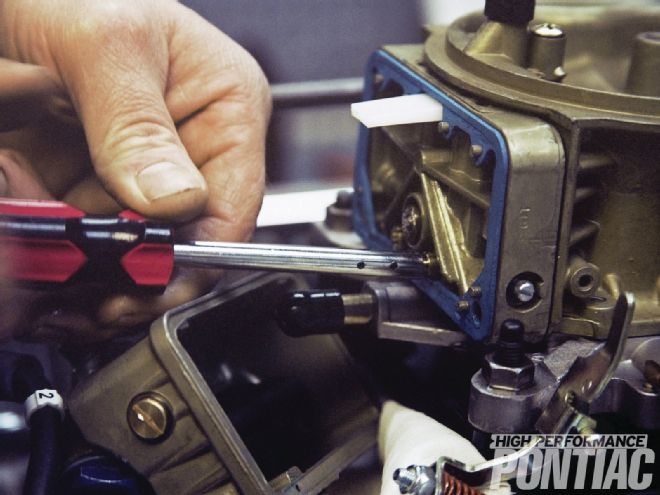

The carburetor was apart more times than we could count dialing-in each gasoline.

The carburetor was apart more times than we could count dialing-in each gasoline.

Spark knock zone is a phrase that has nothing to do with the fuel, but will impact the octane. This has more to do with skewing and variations in the ignition timing caused by sloppy components that alter the ionization event on each bore and are not linear in the amount of lead in relation to engine rpm. A poorly made or worn distributor bushing, or excessive timing chain slop or wear, are the key contributors to altering the spark knock zone. Often an engine is tuned to eliminate audible ping or detonation on only one or two cylinders. This is due to sloppy and inconsistent ignition events that scatter the timing a few degrees in each direction. For this reason, it’s best to confirm the operation of the distributor at higher rpm and not just at idle or off idle.

Another caveat is that we are only testing under full throttle and maximum power. The octane of modern gasoline is the average of the Motor Octane Number (MON) and Research Octane Number (RON) values. This average is identified as the AKI for anti-knock index. The RON is more critical for part-throttle operation under lower inlet temperature, while the MON better represents full-throttle octane tolerance and hotter charge air. The AKI was established since a vehicle can and will be operated under many different conditions and thus, needs to perform well in all of them.

With every fuel, Craig ran a loop of jet and timing to determine what the Pontiac liked. The dyno sheet was the indicator of the final tune.

With every fuel, Craig ran a loop of jet and timing to determine what the Pontiac liked. The dyno sheet was the indicator of the final tune.

The Results

We left the engine on the dyno from our baseline testing covered in the Aug. ’12 issue. HPP came back to RaceKrafters the next morning to perform the octane test with the Rockett Brand fuel. This meant that nothing was disturbed and the weather conditions were almost exactly the same or as close as earthly possible. The baseline was with the local sourced unknown brand 92-octane fuel, and the results were thoroughly covered in the last issue. Next we would test the regular grade 88-octane Rockett Brand Racing Fuel and the company’s 94 and 100 octane blends back-to-back on the same morning.

The weight (specific gravity) of each fuel was different:

Variation in the chemical composition required minor jet changes to optimize each fuel and are noted in the dyno charts.

Ignition advance was not a function of abnormal combustion in our test engine since none was present. It was altered to optimize the power and did not vary as much as you would have thought.

This is total timing in at 2,900 rpm for each fuel:

Local-sourced: 92-octane, 32 degrees

Rockett Brand: 88-octane, 32 degrees

Rockett Brand: 94-octane, 32 degrees

Rockett Brand: 100-octane, 34 degrees

As you can see, the Pontiac did not need any significant alteration to the ignition curve even when the octane varied by 12 points.

What was even more impressive was the average power and torque for the entire test run from 3,300 rpm to 5,300 rpm.

The difference in average power and torque from the 88-octane fuel to the 100-octane was only 3.03 and 3.39, respectively.

Average Power Fuel and OctaneHPTQ Local-Sourced 92435.57534.53 Rockett Brand 88434.63533.32 Rockett Brand 94436.89536.19 Rockett Brand 100437.66536.71As was covered thoroughly in the Sept. ’11 article, the octane of the gasoline is only one part of the story. The energy content in Btu, the chemical composition, and most important the burn speed, all impact how the engine performs. As the testing proved, the Mule was nearly benign to the fuel fed to it, and proved some wrong about Pontiac engines and octane tolerance, the author being one of them (see sidebar).

What our testing has proven is that if a Pontiac engine is built properly with the correct combination of parts, excellent power can be made with regular grade gasoline. Once octane creep takes hold, then these results would most definitely change. The trick is not to let the carbon build-up and your engine should be fine.

Other things to consider are during our dyno testing the engine only experienced peak power for around eight seconds. Driving a Pontiac is certainly different than that, but also it is not making anywhere near peak power. It is the author’s opinion that a properly tuned 9:1 Pontiac of substantial power can be very happy on regular-grade fuel for most if not all driving conditions. In this day and age of $4-per-gallon fuel, that little difference can go a long way.

How great is it to brag that your engine can run on regular and still make just shy of 500 hp? That’s why we love Pontiacs!

The red plot shows the best pull with the 88-octane fuel (551 lb-ft, 488.6 hp), the blue with the 94 (554.2 lb-ft, 489.1 hp) and the green with the 100 (552 lb-ft, 493.0 hp). Not shown since it was covered in the last issue is the 92-octane test, which produced 551 lb-ft and 491.8 hp.

HPP Engine Buildup Worksheet

Engine displacement: 467 ci

Bore/stroke: 4.185 / 4.250-in

Bore/stroke ratio: 0.98:1

Rod/stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Preparation: Cooked, magged, line-bored, line-honed, decks squared with BHJ, bored and honed with torque plates

Deck height: 10.205-in

Crank: Butler/Eagle forged

Preparation: Balanced, polished

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Preparation: Pin end honed to proper size, balanced, big end checked for proper size

Bearings: Clevite, plain shell, tri-metal

Preparation: Clean, check for proper clearance in rods

Pistons: Butler/Ross forged flat-top with valve reliefs

Preparation: Pin fit, check size, clean

Piston-to-deck height: 0.010-in below

Piston pins: Ross, 0.990-in floating, 0.155-in wall

Method used to retain pins in pistons: Spiro Locks

Rings: Total Seal; moly top; ductile second; three-piece oil; 1⁄16-, 1⁄16-, 3⁄16-in

Preparation: File-fit, clean

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road Race Series 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2ccs

Maximum flow at 28 inches of pressure

Lift Int. Flow CFM Exh. Flow CFM

0.100 66 55

0.200 133 106

0.300 191 149

0.400 224 170

0.500 236 182

0.600 250 186

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job: Intake—45, 60, 75, and 82-deg, 82 is hand blended into 75-deg., exhaust—45-deg, 12mm radius

Retainers: Comp Cams, steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valve guides: K-line bronze liner

Valve seals: Steel/Viton

Rocker studs: ARP 7⁄16-in

Rocker arms: Comp Cams aluminum full roller, 1.65:1

Pushrods: Manley 3⁄8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic roller

Duration at 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe separation angle: 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 137 lb/in

Open Pressure: 290 lb/in

Timing Chain: Comp Cams double-roller

Induction

Carb: Holley 4150 HP 750-cfm, mechanical secondaries

Intake Manifold: Edelbrock Torker II

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5mm

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32-in

Collector Size: 3.00-in

Gaskets

Brand: Fel Pro

Eating Crow

Within the Pontiac community there are enthusiasts who adore Ponchos but are also very familiar with other makes of engines, and I am one of them. I make no effort to hide that I am an engine guy above all else.

Over the years, the Pontiac cylinder head design and combustion chamber have often become a target of ridicule by many engine people. It does not take long for the conversation to drift toward the chamber shape, port design, and spark plug location in relation to the bore center. The truth is that by modern standards the Pontiac cylinder head design is outdated. The problem being the human element is skewing this opinion.

It is not fair to compare a 35-plus-years-old Pontiac head design to a 2012 design, such as the latest LS series engine. Technology has advanced greatly since the Pontiac cylinder head was developed. But if you look at competing brands from the same era, the Pontiac cylinder head is seen in a different light. The Mule engine build has shown that to me with clarity. Let me explain.

I never doubted the Mule’s ability to make power, but I was cynical about the thermal efficiency, fuel consumption, and the octane tolerance.

Any engine with a 4.185 inch bore and an O.E. cast-iron cylinder head that can make just shy of 500 horsepower on 88 octane fuel with only 32-degrees of ignition lead and a BSFC of around 0.38 needs to be applauded.

A good qualifier of any engine is the amount of ignition lead required to produce peak torque. The slower the combustion chamber burn rate, the more lead is required. Granted, a modern LS engine would make the same power with 20 degrees of advance. A 1975 (the year of our engine) Chevy, Ford, or Mopar would need about 8 to 10 degrees more timing to make like power if it even reached that level. Likewise with only 9.1:1 compression ratio, I thought the BSFC would be around 0.43.

I have always loved and respected Pontiac engines but did my fair share of doubting the cylinder head. The Mule has changed that for me. I hope that you too can look beyond the power numbers and with pride know that a Tin Indian is a force to be reckoned with. I am enjoying my meal of crow and could not be happier to be wrong.—Ray T. Bohacz