Some engines just won’t go away. Back in the May ’11 issue, we brought you the first part of our budget-built 400 small block Chevy. The idea was to bolt a set of iron Vortec heads on a junkyard 400 small block Chevy, add a cam, and enjoy the torque. Right away, we ran into snags. The block was so nasty it demanded help while retaining the stock crank, pistons, and rods. The cam failed with less than a week before our deadline necessitating an unplanned thrash to rebuild the engine a second time because all that dead cam metal wiped out the main bearings. By the time we were finished, we had never worked so hard to produce so little power. The 400 small block Chevy problems were multiple: The cylinders waffled like ice cream cones, preventing anything approaching ring seal, and the compression was a sickly 8.2:1 due to ugly 0.060-inch piston deck heights. In case you missed the story, the best power numbers were gained with a set of GM Performance Parts Vortec heads supplied by Scoggin-Dickey, and even then the 400 small block Chevy managed only 401 hp and 458 lb-ft of torque. We were underwhelmed.

Rather than kick the motor to the curb, we decided to build this engine correctly. The plan was to retain the original test’s cam, Vortec heads, Weiand intake, Holley 750-cfm carburetor, and exhaust headers so we could honestly evaluate the power increase from better cylinder sealing and a bump in compression. The difference was astonishing. You’ve probably already jumped ahead to the dyno test, but if not, the new torque numbers came in at a tire-shredding 501 lb-ft at 4,000 rpm, and horsepower leaped up to 466 at 6,000 rpm. That’s a peak horsepower bump of 65! We did cheat a little with a couple of new parts, but you’ll have to read the whole story to find out what we did.

While we originally planned to reuse the stock crank, Scat’s Tim Lieb suggested adding an important option. All production 400 small-blocks were built as externally balanced engines. The problem with building a performance 400 that might see rpm above 6,000 is the external weight spinning around on the crankshaft snout; it acts like a rock on the end of a string, adding load on the crankshaft that could cause eventual failure of the front main bearing. Lieb suggested an internally balanced crankshaft assembly that would require 6-inch rods and a short- compression-height piston to allow room for larger crankshaft counterweights. This package costs a little more than the standard 5.7-inch rod and cast crank system, but it offers much greater durability. One other possible advantage is the improved rod-length-to-stroke-ratio from the 6-inch connecting rods. Since it’s always a possibility that we will lean on this engine harder at a later date, we opted for the internally balanced rotating assembly and had Scat balance it for us.

The most obvious change to this different rotating assembly is that with a 6-inch rod, the piston compression height becomes very short, which moves the wristpin up into the oil control ring. This requires an oil support ring that is supplied with the pistons. It’s important to note that this support ring comes with a small dimple that should be placed with the raised portion facing down so it will not move relative to the piston.

Assembly

Once our machine shop, Barrington Engines, ensured that all the cylinders were properly bored, the torque plate was honed, the main bearings were align-honed, and the decks were level, we had a great foundation. By the time Barrington finished squaring this block and making the holes round, the thought occurred to us that we had $800 invested. We looked up the price of a Dart SHP block from Summit. It comes in at $1,499.41 (plus shipping). While this block is more expensive, it’s a new casting with four-bolt mains and 350-size main journals, which means slower bearing speeds over the larger stock 400 size. You will still have to hone this new block, so factor in that cost—it’s worth considering before investing $800 in a 40-year-old block.

We will not spend too much space documenting the assembly other than to mention that we did have to mix in quite a few Federal-Mogul 0.001-inch undersize bearing halves with the Scat rods to get bearing clearances to achieve our ideal 0.0025-inch clearance target. The main bearings were easier because Barrington align-honed housing bores, which established more consistent bore diameters. We also mocked up the engine to measure deck heights and then had Barrington machine the deck surfaces to create a much more consistent deck height.

Cam Specs

Comp Cams Thumpr 287TH7 hydraulic flat-tappet camshaft Camshaft Duration at 0.050 Lift Lobe-Separation Intake 235 0.490 107 Exhaust 249 0.475

Testing Day

With an increase of two full points of compression and good ring seal, we expected some serious power improvements over the stock baseline, and we weren’t disappointed. Right at the first pull on the dyno with 36 degrees of timing (versus 44 degrees with the old engine), the 406 grunted out 486 lb-ft of torque compared with the previous 458 and produced between 20 and 30 lb-ft of torque increase across the board with similar gains in horsepower with the peak of 436 hp at 5,200 rpm. The biggest problem now seemed to be that we needed some way to make the engine breathe better at higher engine speeds to make more horsepower. The limitation seemed to be valve lift, so we thought the simple addition of a set of 1.6:1 rocker arms might help.

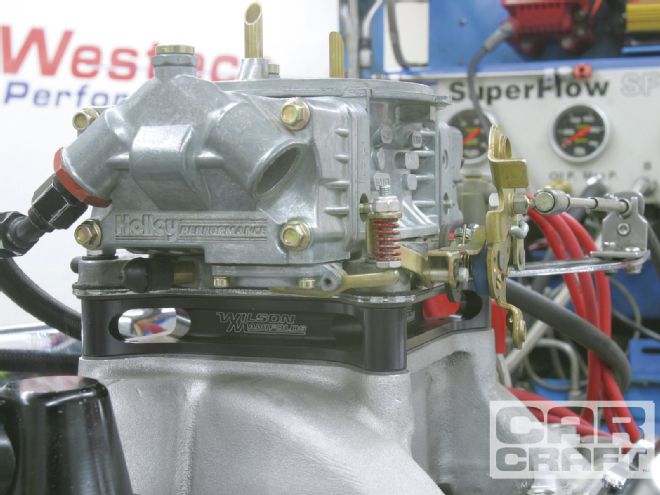

Generally, an increase from 1.5:1 to 1.6:1 rockers is usually worth about 0.030 inch of valve lift, and since our cam barely made 0.490-inch lift, that seemed like a good solution. We also tried a 1-inch-tall Wilson tapered spacer that was worth roughly 3 hp at the peak with no loss of torque down low. We also drained the 10W-30 break-in oil and tried some thinner-viscosity Lucas 0W-20 race oil, hoping to push over the 500-lb-ft plateau. All these little efforts really paid off. The rockers alone were worth almost 20 hp, which helped us excel to 501 lb-ft of torque and upped peak power to 466 hp at 6,000 rpm, and the engine responded positively to nearly all the changes. All this really proves that quality machine work and proper engine assembly techniques really do pay off with big rewards. We are already thinking about how to make even more power with this 406ci, and we might have to start calling it the BFH because it brings down the big freakin’ hammer on torque.

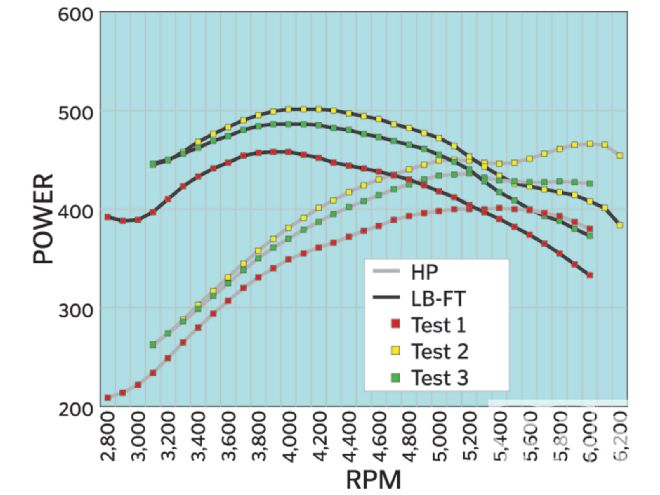

Power Curves

This graph illustrates the big differences in torque between the previous combo and our latest version. Note how the shape of the curves remains basically the same, since we did not change the cam, heads, intake, or exhaust. But look carefully at how the horsepower curve dips slightly between 5,300 and 5,900 on Tests 2 and 3. The dip is more pronounced in Test 3, which is where we added the rocker ratio. Our theory is that the valvesprings are right on the ragged edge and became “fussy” in this rpm range. The fix is a different (not necessarily higher load) valvespring that would probably take care of this. The big news is the huge gain in torque between Test 1 and Test 3. This would make an excellent street engine.

Dyno Numbers

Test 1 is the best power we pulled from the original test of the engine from the May ’11 issue. Test 2 is with the same Bow Tie Vortec heads, Comp cam, Weiand intake, Holley carb, and dyno exhaust with no mufflers. Test 3 added a Wilson-tapered carb spacer and a set of Comp 1.6:1 roller rockers and performance pushrods.

Power Curve

RPM Test 1 TQ Test 1 HP Test 2 TQ Test 2 HP Test 3 TQ Test 3 HP TQ/HP Gain 2,800 392 209 --- --- --- --- --- 3,000 389 222 --- --- --- --- --- 3,200 410 249 450 274 449 274 +39/25 3,400 433 280 462 299 468 303 +35/23 3,600 447 307 474 325 483 331 +36/24 3,800 457 331 484 350 495 358 +38/27 4,000 458 349 486 370 501 381 +43/32 4,200 452 361 485 387 501 401 +49/40 4,400 444 372 480 402 497 417 +53/45 4,600 438 383 473 414 491 430 +53/47 4,800 430 393 465 425 482 440 +52/47 5,000 418 398 455 434 472 449 +54/51 5,200 404 400 440 436 453 449 +49/49 5,400 390 401 417 429 434 446 +44/45 5,600 374 399 400 427 423 451 +49/52 5,800 355 393 388 428 417 461 +62/68 6,000 333 380 373 426 408 466 +75/86 6,200 --- --- --- --- --- 454 --- Peak 458 401 486 436 501 466 --- Avg.* 417.2 357.2 450.4 390.0 465.5 400.3 ---

*Average power numbers were calculated between 3,200 and 6,000 rpm to ensure a fair comparison.

Parts List

Description PN Source Price Used 400 short-block Used Junkyard $120.00 Scat crank, rod, piston balanced Call Scat Summit Racing 1,496.95 Scat 6.00-inch I-beam rods 26000 Summit Racing 251.95* Icon forged piston, -51cc dish IC758 Summit Racing 475.95* Vortec Bow Tie, large-port 25534446 Scoggin-Dickey 985.70 Comp 1.6:1 roller rockers 1016-16 Summit Racing 351.95 Comp Muscle Car 10W-30 oil 1594 Summit Racing 39.75 MSD Distributor, pro billet 8361 Summit Racing 212.95 ARP 400 main studs 234-3701 Summit Racing 77.18 ARP head bolts 134-3701 Summit Racing 108.95 Federal-Mogul cam bearings 1404 Jeg’s 23.99 Federal-Mogul main bearings 140M Jeg’s 65.95 Federal-Mogul rod bearings 7100CH Jeg’s 56.99 Federal-Mogul rod bearings -1 7100CH-1 Jeg’s 86.99 Fel-Pro align bore main seal 2909 Summit Racing 23.95 Fel-Pro 400 head gasket 1044 Summit Racing 141.98 pr. Fel-Pro 1-pc pan gasket 1880 Summit Racing 40.95 Fel-Pro Vortec intake gasket 1255 Summit Racing 32.99 Professional Products balancer, 6.75 80000 Summit Racing 54.95 Federal-Mogul oil pump pickup Z2241246 Summit Racing 11.95 Federal-Mogul cam bearings Z1235M Summit Racing 17.95 Federal-Mogul oil pump drive Z2246146 Summit Racing 8.95 Sealed Power brass freeze plug Z381 Summit Racing 18.95 VHT Chevy orange paint DE1620 Summit Racing 6.95 GMPP self-align 3/8-inch rockers 12495490 Summit Racing 61.95 Weiand Speed Warrior intake 8501 Summit Racing 209.95 Holley 750 mechanical-secondary carb 0-4779 Swap meet 150.00 Comp nitrided Thumpr hydraulic cam 12-601-20 Summit Racing 274.95 Comp Pro Magnum hydraulic lifters 858-16 Summit Racing 94.95 Bosch Super + spark plugs 7975 Auto Zone 15.92 Wix oil filter 51069 Summit Racing 5.95 Wilson tapered 1-inch spacer 004110 Wilson Manifolds 128.75 Subtotal 4,929.34 Machine Work 810.00 Grand Total $5,739.34

Machine Work

Operation COST Hot tank block $60.00 Bore and torque-plate-hone 290.00 Align-hone block 190.00 Deck block 190.00 Install cam bearings 60.00 Hone damper 20.00 Machine Work total $810.00

*These separate part numbers and prices for the pistons and rods are for reference.