In racing, just as in life, eventually bad things are going to happen. It's a lesson most of us learn as kids when that great toy we got for Christmas broke on the 26th.

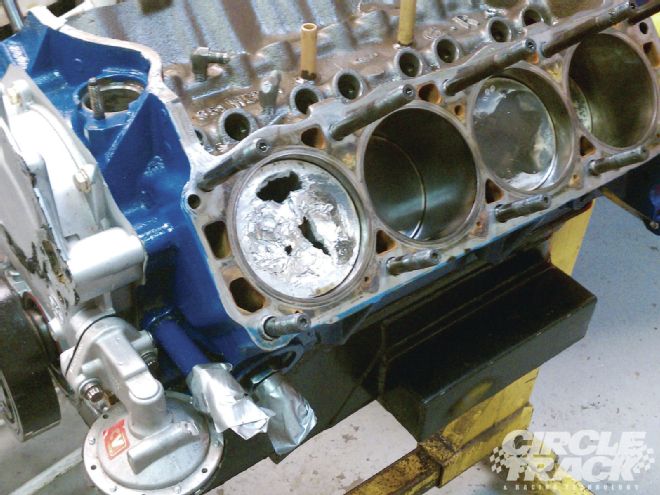

As soon as the staff at KT Engines pulled the head on this Windsor Late Model Stock-level race engine, it was clear that there was some major damage that needed to be fixed. The key with a grenaded engine like this is to find all the damaged components and either repair or replace them. If one slips through the cracks, it can quickly destroy your freshly rebuilt engine and leave you right back where you started—but a lot poorer.

As soon as the staff at KT Engines pulled the head on this Windsor Late Model Stock-level race engine, it was clear that there was some major damage that needed to be fixed. The key with a grenaded engine like this is to find all the damaged components and either repair or replace them. If one slips through the cracks, it can quickly destroy your freshly rebuilt engine and leave you right back where you started—but a lot poorer.

That's the lesson we learned as kids; the lesson we learn as adults is that sometimes things go wrong and there's nothing you can do about it, but sometimes you can. The fancy word for it is "failure analysis," but it really just comes down to figuring out what went wrong so you can fix it next time. Yes, we like to keep things simple.

With that in mind, we've got a couple of examples of how engine builders attack engine failures to diagnose the problem, or problems, and make sure they don't keep cropping up to bleed your racing budget dry. When repairing or rebuilding a failed race engine, it's also critical to make sure you've identified all the damaged components and either replace or repaire them so that they don't in turn cause a failure of their own.

While working on other projects with KT Engine Development, two broken race engines came in, one right after the other. The first was a Ford Windsor which the owner had bought used on the cheap and brought in for a rebuild—also on the cheap. "When you are trying to rebuild an engine that you don't know the history on, it's difficult," explains owner Ken Troutman. "You have to do a lot of detective work to try to determine how well the engine builder put it together the first time and how long the parts have been in the engine. It seems like everybody who is selling a used race engine will tell you that it has just been rebuilt, but the reality is that's rarely the case.

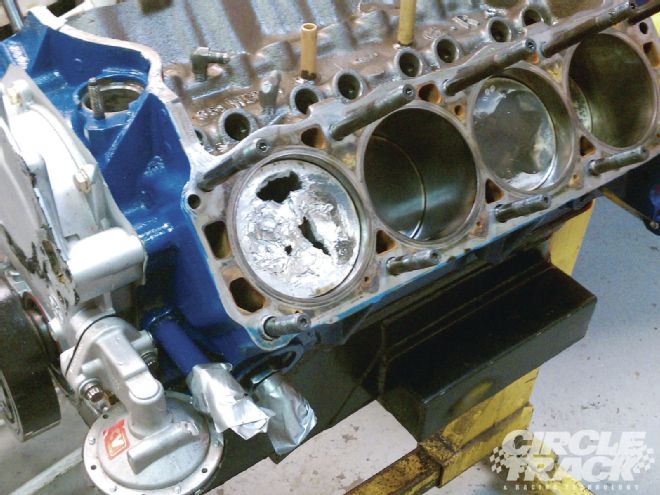

Here’s a look at the combustion chamber for that cylinder. From all the damage around the exhaust port it’s obvious that the exhaust valve broke, and steel from the valve was pushed up by the piston and smashed into the cylinder head. The intake valve was still in place, and that partially protected the seat around the intake valve.

Here’s a look at the combustion chamber for that cylinder. From all the damage around the exhaust port it’s obvious that the exhaust valve broke, and steel from the valve was pushed up by the piston and smashed into the cylinder head. The intake valve was still in place, and that partially protected the seat around the intake valve.

"When we rebuilt this Windsor," Troutman continues, "we wanted to replace everything we had a question about, but the customer was on a very limited budget. One of the things we specifically questioned was the valves, but the customer said he didn't have the money. Unfortunately, a valve failed pretty early on and now he's got to spend a lot more money to get the motor back together and running.

"I understand that it can be difficult to spend money to replace parts that look like they should be fine, but the upfront cost of doing things right the first time is almost always a lot cheaper than the cost of repairing your mistakes later."

The second broken engine was a motor that came in from a new customer. This engine had never been touched by KT Engines, and the customer was coming to the shop because of previous engine failures at another shop. This one turned out to be a broken connecting rod, but the real cause is just a bit more involved. Let's take a closer look at both.