Hot rodding's pioneers had to be self-reliant, making stuff for themselves. Today, just about everything is available out of a catalog . . . at least for mainstream engines. But what if you have an oddball engine or are just plain bored with cookie-cutter parts combos? For those who dare to work on an engine for which there is little or no aftermarket support, the only solution is a back-to-basics approach, adapting parts from other engine makes, returning to original machining techniques, and even custom-fabricating stuff from scratch. Here, we'll take a look at some of these old-school techniques using by way of illustration a unique Buick '64 to '67 300 V8-based stroker assembled by Dave Nelson at Joe Sherman Racing engines. We'll also examine exotic overhead-cam conversions pioneered by home builder Pete Aardema.

This obsolete Buick 300 V8 made 390 hp and 422 lb/ft using old-school hot rodding.

This obsolete Buick 300 V8 made 390 hp and 422 lb/ft using old-school hot rodding.

Plan and Investigate!

If you plan on tackling a niche engine, first identify the pluses and minuses of the particular design and how they may be overcome within your budget constraints. What's available and what must be custom made? One advantage we have today that our hot rodding granddads didn't is the Internet. Google for niche manufacturers-there may already be a specialist for your weird motor. Check forums and message boards for your brand. Browse online catalogs. Look for print catalogs. In short, get your ducks in a row before you get out your wallet.

The Buick 300, Nelson's chosen project, was a transitional engine between the original 215ci aluminum V8, the also transitional 340, and the late Buick 350 small-block. The Buick V6 and modern Rover V8 are close relatives. There are many similarities, but there are also differences in head layout, deck height, and internal components. Some parts from the later engines can be used.

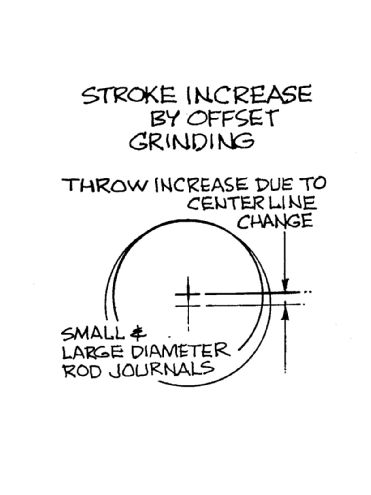

You can increase stroke by offset-grinding the original rod journals to a smaller size used by a different engine for which bearings are readily available. Care must be taken not to run into the internal oil passages.

You can increase stroke by offset-grinding the original rod journals to a smaller size used by a different engine for which bearings are readily available. Care must be taken not to run into the internal oil passages.

Investigation also revealed the 300's shortcomings: restricted heads with small valves, not enough cubes, a weak valvetrain, and (common to all Buick engines) marginal oiling. Due to its short production span, there is little direct aftermarket support for a 300 (gaskets and bearings are still offered). If this was a bucks-up build, anything up to and including a custom billet crank could be made, but sticking to a traditional budget approach, Nelson found it feasible to drop a 3.85-inch-stroke 340/350 crank into the 300, replacing the smaller engine's 3.4-inch-stroke crank. With an appropriate overbore, it yields nearly 350 ci in a much more compact package than the later Buick 350. The 300, 340, and 350 all have the same 2.0-inch rod journals, but the main bearings are much larger-3.0 inches for the 340/350 versus 2.50 inches for the 300. The 340 and 350 blocks have much taller deck heights than the 300s. Turning down the crank's mains to fit the 300 block results in reduced main-bearing speeds, lighter rods, and about a 60-pound weight savings.

More Cubes

Increasing displacement is one of the most fundamental of hot rodding's paths to power. You can increase displacement by overboring the cylinders, increasing crankshaft stroke, or both. To find an engine's cubic inches (CI) use the following formula:

CI = Bore² × 0.7854 × Stroke × No. of Cyls.

Max overbore is limited by cylinder wall thickness. Most engine builders like to see no less than 0.150 inch of wall thickness on the thrust side after boring. Determine cylinder wall thickness by sonic-checking the block.

Increasing the stroke is limited only by the physical constraints of fitting everything within the engine block, so it yields much more of a displacement increase. For example, on the popular Chevy 454 V8 (4.25-inch bore × 4.0-inch stroke), a 0.060-inch overbore (4.31-inch final bore size) yields a 466.9ci engine, but keeping the stock 4.25-inch bore size and increasing the stroke by 1/4 inch to 4.25 inches results in 483.3 ci. If the engine was both bored 0.060 and stroked 1/4 inch you'd get 496 ci.

More Stroke

One tried-and-true method of increasing crank stroke is offset-grinding an existing crank, which moves the rod journal centerlines farther away from the main-bearing journal centerlines. The new, reduced-diameter, offset journal must be the same size as one used by a different (but still commonly available) rod. The 2.0- and 2.1-inch small-block Chevy and 2.2-inch big-block Chevy rod-journal sizes are the most popular new journal sizes, with a huge variety of different-length aftermarket rods available off the shelf machined for these bearing sizes. The pin ends of these rods are usually sized for Chevy small-block (0.927-inch) or big-block (0.990-inch) piston pins, which means you'll probably need custom pistons, too.

When regrinding rod or main journals to a new, smaller size, the journal's fore-and-aft dimension must also be compatible with the new rod or crank bearing lengths. Up to a point, Hank Bechtloff (aka Hank The Crank) says a journal can be widened by a good machinist, but not narrowed. Large-chamfer bearings (such as Clevite H-series) can be used to clear remachined journals' larger fillet-radii. If needed, carefully sand the rods to increase side clearance (ideally about 0.015 to 0.020 inch on typical steel-rod V-type engines).

Oil holes can also cause problems. Obviously, you don't want to break into an internal oil passage, but there's also a more subtle issue: Because the oil-feed passage between the main and rod journal is drilled at an angle, as the journal size is reduced, the hole surface migrates off center. This is usually a minor issue on a nonoffset-ground main journal and can be corrected by chamfering the journal hole toward the bearing's groove or hole. But when offset-grinding rod journals, the crank may require reindexing to prevent the oil hole from moving toward the fillet radius; the balancer and timing gear marks must be correspondingly remarked or relocated.

Stroke can also be increased by welding additional material to the top-side of the rod journal. Ultimately, a billet stroker crank can be made custom-made for any engine-but get out your wallet.

Steel cranks ground or welded to yield a different journal size should be heat-treated again to restore metallurgical strength. This is not necessary on most factory iron cranks that lack any surface heat treat. However, sophisticated (albeit costly) ion heat-treating can significantly increase an iron crank's strength if you're stuck with one.

With its 2-inch rod journals, offset-grinding the 300 Buick crank wasn't practical, and welding on its cast-iron crank isn't really recommended-hence Nelson's decision to grind down the mains on the readily available longer-stroke 340/350 Buick crank. Both 300 and 340/350 cranks have the same main-bearing fore-and-aft width; only minor chamfering was needed on the oil holes.

Component Stack-Up

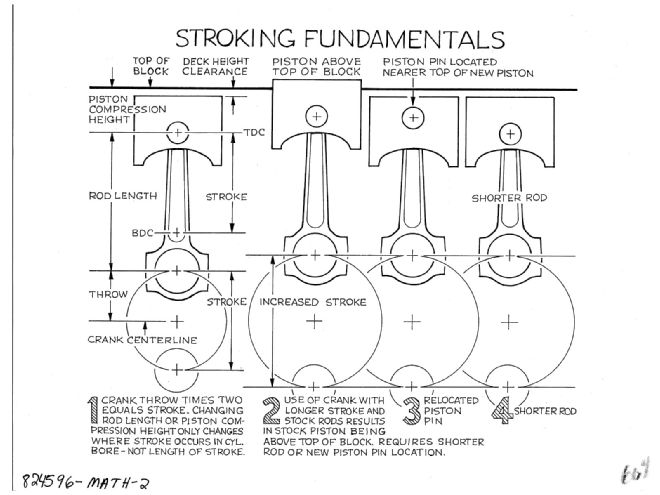

On any custom stroker, the piston and rod assembly must not poke up out the top of the block at top dead center (TDC). Including head gasket compressed thickness, on a steel-rod engine you want about a 0.040- to 0.045-inch assembled piston-to-head clearance. With typical 0.040-inch-thick composition head gaskets, this usually calls for near zero piston deck heights. When the pistons fall too far below the deck (say, more than 0.020 inch with a 0.040-inch-thick head gasket), quench is lost, reducing combustion efficiency and actually increasing detonation potential even though (with the same piston dish/dome volume) the static compression ratio ends up lower. To determine the total height (H) of a given reciprocating assembly:

H = Piston CD (pinhole centerline to piston deck) + Piston Deck Height (piston deck to top of block) + Conrod Center-to-Center Length + 1/2 Stroke

You can change any combination of the four variables (rod length, piston compression height, deck height, and stroke) the required amount to realize dimension H-whichever is cheapest or easiest for the application.

H is the total distance from the crank centerline to the top of the block deck; this can be the same as the block theoretical blueprint deck height or the actual measured deck height. Most virgin stock blocks come taller than the theoretical minimums, but they may need minimal milling to at least square them up or compensate for surface wear. Blocks can also be milled below the blueprint dimension, but care must be taken not to excessively thin out the deck. The amount of acceptable remaining thickness after block-milling varies per block material, head gasket effectiveness, and head bolt clamp load. Assuming a worst-case iron block with four head bolts per cylinder, Bechtloff recommends maintaining deck thickness at no less than 0.300 inch; double that value for an aluminum block.

Ring Groove Allowance

Stroker pistons usually end up shorter than the originals, but there still needs to be enough room for the rings. Racers routinely run the oil ring through the pinhole using a steel support rail, a technique increasingly popular on the street. Still, you don't want to do it unless you have to. To determine the minimum safe compression distance (CD) without running into the pin, add each ring's thickness plus half the piston pin diameter to a minimum safe value for the distances between the piston deck and the top ring, each ring element, and the oil ring and the top of the pinhole. The example below uses Bechtloff's minimum recommended distance values (in red) for a piston that has a 1/16-1/16-3/16-inch ring package and a Chevy 0.927-inch-od pin.

Rod length or piston compression height (piston pin location) changes don't affect bore size or stroke length (so they won't alter displacement), but changes in one or both of these dimensions may be needed after any stroke change to properly locate the top of the piston for desired TDC deck height clearance.

Rod length or piston compression height (piston pin location) changes don't affect bore size or stroke length (so they won't alter displacement), but changes in one or both of these dimensions may be needed after any stroke change to properly locate the top of the piston for desired TDC deck height clearance.

Piston deck to ring 1 0.150 Ring 1 thickness 0.0625 Ring 1 to ring 2 0.150 Ring 2 thickness 0.0625 Ring 2 to ring 3 0.100 Ring 3 thickness 0.1875 Ring 3 to top of pinhole 0.050 1/2 piston pin od 0.4635 Minimum piston CD 1.266

Bottom-End Clearance

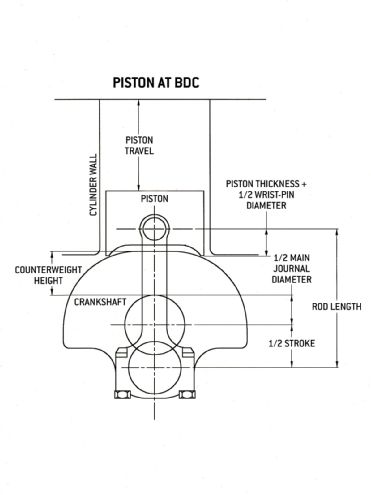

At the opposite end of the stroke (BDC), the piston bottom must clear the crank. Counterweight clearance height (C) is determined primarily by the rod length for a given stroke. The following equation will get you close, but in the final analysis, the rotating assembly must be physically mocked up and checked in the actual block. After all, besides possible piston-to-crank interference, the rods or rod bolts might hit the oil pan rails, the bottom of the cylinder bores, or even the cam.

C = Rod center-to-center length - ( Stroke main journal od Wrist pin od ) 2 - Piston thickness below wrist pin hole - Clearness value (usually 0.100)

If a piston clearance problem exists, either the crank counterweight or the piston can be remachined. Don't machine the counterweight in a circular arc or there won't be enough weight left for balancing purposes. Instead, the counterweight must be cam-ground for clearance by an experienced custom crank shop. Even so, Mallory heavy metal may still be needed for balancing. Alleviating rod interference may require special rod bolts, a profiled rod, a reduced-base-circle cam, and grinding the block.

Nelson's Buick Solution

You'd think that on the short-deck Buick 300 it would be hard to accommodate a 340 crank. But stock Buick pistons are tall and bulky: One of the reasons Buick engines have such tall decks, relative to the stroke, is because Buick never adopted slipper-skirt pistons in any of its engines. A full-skirt piston requires a longer rod plus a tall deck for the piston to clear the crank counterweight at BDC. With a modern slipper-skirt piston that has the right CD and dish/dome volume to yield the desired static compression ratio, the original 300 rod can be retained without any deck height problems.

At BDC, the piston skirt must clear the crank counterweight. To find counterweight height, subtract from the rod length half the stroke, half the main journal diameter, half the wristpin diameter, the piston thickness below the wristpin hole, and a 0.100-inch clearance figure. A negative result means the crank or piston must be ground for clearance.

At BDC, the piston skirt must clear the crank counterweight. To find counterweight height, subtract from the rod length half the stroke, half the main journal diameter, half the wristpin diameter, the piston thickness below the wristpin hole, and a 0.100-inch clearance figure. A negative result means the crank or piston must be ground for clearance.

Today most strokers use custom-made pistons. Cost has come way down for popular stroker combos, particularly for common 4-, 4.125-, or 4.25-inch bore sizes and their standard oversizes. If feasible, overboring to these common sizes saves bucks, broadens your ring choices, and allows achieving nearly any compression ratio. Modern piston makers can even digitize oddball head chambers and make pistons to match.

But if you're stuck with a weird bore size, a fully-machined custom forged piston set can run $600 to $800 or more. A possible budget solution is to find a standard piston from another engine that works in your build. Look for a piston with the right CD, the same or similar piston pin size (if using stock rods), the necessary dome or dish volume, and (if needed) valve notches in the correct location. Domed pistons from another make or engine style probably won't work, but a flat-top or dished piston from an engine with similar-style heads and intake/exhaust valve layout can often be used.

For about a quarter the cost of customs, Nelson found Federal-Mogul and Silv-O-Lite cast hypereutectic pistons for a late 3.8-inch-bore Olds 307 that work in the Buick with minor mods. The 300 block's stock bore is 3.76 inches, mandating a 0.040-overbore to fit the Olds pistons (300s can safely go 0.060 over). Final displacement comes in at 349 ci. To accommodate the larger 0.980-inch Olds press-fit piston pin, the stock Buick rods' small-ends were bored 0.040 over.

The 307 Olds pistons are basically a replacement-style design setup for 5/64-5/64-3/16 rings. There's power to be had with modern, thin, lightweight rings. Nelson used a special Total Seal file fit 1.2mm-1.2mm-3/16-inch package that comes with spacers to take up the slack in the wider top two ring grooves.

Even these replacement-style pistons have antifriction skirt coatings that allow tighter piston-to-wall clearances for quieter operation and superior oil control. Such coatings on pistons and engine bearings are becoming increasingly mainstream.

Compression Ratio

On the Buick, the static compression ratio ended up around 10.0:1 while still maintaining 0.045-inch quench with thin steel shim head gaskets. That's toward the high end for iron heads on premium pump gas, but with the cam of choice, it cranked 185 psi, making it viable. Generally, as cam duration increases, the engine becomes less detonation sensitive (assuming similar lobe displacement angles). KB/Silv-O-Lite has a Web-based dynamic compression ratio calculator that helps you select the max feasible static compression ratio based on your cam specs.

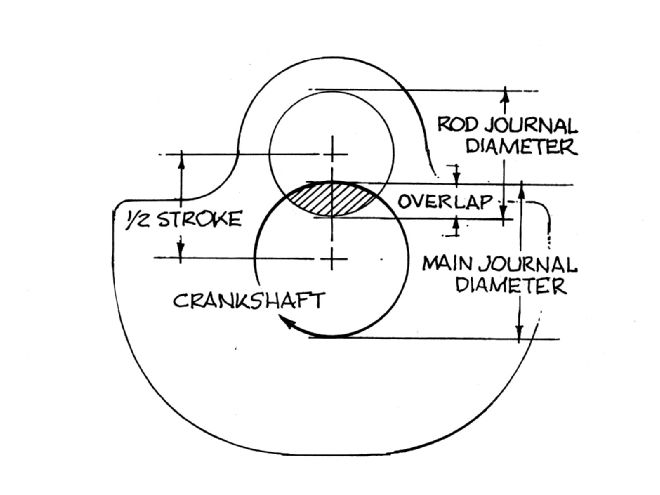

Rod and main journal overlap is a critical factor for maintaining crank -strength and rigidity. As the stroke increases, the amount of overlap decreases, weakening the crank. The amount of acceptable overlap is determined by the strength of the crank material, the engine's power output, and its intended use.

Rod and main journal overlap is a critical factor for maintaining crank -strength and rigidity. As the stroke increases, the amount of overlap decreases, weakening the crank. The amount of acceptable overlap is determined by the strength of the crank material, the engine's power output, and its intended use.

More Cam

Cam technology has come a long way from the classic era, but the latest profiles may not be listed in the catalog for oddball engines. Even if no catalog cams are listed, cam blanks may still be available for your engine; call and inquire. Assuming availability, spec out a modern profile for your niche engine-not some old-school hoary classic.

Comp Cams still has Buick 300 cam cores and whipped up a special for Nelson. Custom-ground using Comp Cam's latest XFI profiles with a 108-degree lobe-separation angle and installed on a 105-degree intake-lobe centerline, the Buick cam specs out at 236/241 degrees (at 0.050) and 0.519/0.515-inch valve lift (with 1.5:1 rockers). Order custom grind 98-00-5-H108 (intake lobe No. 5088/exhaust lobe No. 5107).

No new cam blanks available? Your old, mild (but still undamaged), stock cam can often be reground into a performance profile. Ultimately, a completely custom billet steel cam can be made for any engine. At that high-buck level, you probably want to step up and maximize your investment by specing a solid roller cam.

Stock Buicks used a full-skirt piston (right). Nelson fit a 340/350 Buick long-stroke crank in the short-deck 300 using 300 rods and compact '85 to '90 slipper-skirt 307 Olds pistons-either Federal-Mogul (PN H801CP, center) or Silv-O-Lite (PN 1639HC, left) work. The latter is shown already modified for crank clearance: 0.080 inch removed below the pin boss (A); 0.030 from the skirt scallop (B).

Stock Buicks used a full-skirt piston (right). Nelson fit a 340/350 Buick long-stroke crank in the short-deck 300 using 300 rods and compact '85 to '90 slipper-skirt 307 Olds pistons-either Federal-Mogul (PN H801CP, center) or Silv-O-Lite (PN 1639HC, left) work. The latter is shown already modified for crank clearance: 0.080 inch removed below the pin boss (A); 0.030 from the skirt scallop (B).

The other half of the cam equation is getting lifters that fit. There are three common lifter diameters (in inches): 0.842 (most GM), 0.875 (Ford), and 0.904 (Chrysler and AMC). Engines with nonstandard-size lifters that are no longer commonly supported can often have their lifter bores drilled oversize or reduced with a bushing as needed to one of these standard sizes. If the engine oils through the pushrods, the lifters must have an oil hole and groove in the right position so they won't pop out of the bores at full lift.

The original Buick shaft-mount valvetrain oils through the block, heads, and shafts, but Nelson substituted Chevy lifters (Comp PN 812-16) that have the requisite oil holes and grooves in the right place to direct oil through the pushrods. This was needed because he planned some radical valvetrain and head upgrades.

More Head

There are modern aftermarket aluminum heads for the 215 and its Rover descendents that can be adapted, but on the 300 Nelson says they'd require a fabricated intake. Sticking to his budget, he instead chose to maximize the performance of the stock castings. That involves installing larger valves followed by extensive head porting. While the Buick '65 to '67 300 and '66 to '67 340 were equipped with larger ports and valves than the earlier 215 and '64 300, larger is a relative term: The 1.81-inch intakes and 1.375-inch exhausts and general port layout need major help to achieve the flow numbers required to feed a 350-sized engine.

The dished Olds piston (left) lacks valve notches, but they weren't needed on this build thanks to the Buick's near-vertical valve angle and Nelson's cam. The U-shaped dish matches nicely with the Buick combustion chamber-much better than the original Buick slug (right).

The dished Olds piston (left) lacks valve notches, but they weren't needed on this build thanks to the Buick's near-vertical valve angle and Nelson's cam. The U-shaped dish matches nicely with the Buick combustion chamber-much better than the original Buick slug (right).

In lieu of costly custom-made aftermarket items, appropriately dimensioned valves from other engines can sometimes be used. Compared with other pushrod domestics, the 215/300/340 Buicks have very short, 4.62-inch valves. The intake/exhaust valve centerline spacing is very tight, so there's minimal room to go larger. In fact, finding good, modern valves without shelling out big bucks for custom jobs takes a little effort. After searching the Speed-Pro catalog, Nelson found valves from later Buick V6 engines that work, delivering superior performance and durability for less money.

After Nelson did a good multiangle valve job, the heads were heavily ported, with more than 100 hours on the flow bench. Stock, the heads peak out at just 0.450-inch lift, flowing only 174 cfm on the intake side and 104 cfm on the exhaust (at 28 inches of water). The extensive porting generated improvements throughout the lift range, with peak flow now occurring at 0.500-inch lift: 206 cfm (intake) and 134 cfm (exhaust). That's sufficient to support about 425 hp on a maximum-effort, high-compression, normally aspirated, single-four-barrel engine.

Better Valvetrain

As on many old-school engines, the stock Buick shaft-mount valvetrain was marginal even for the stock cam and low-pressure production springs. Nelson's use of late-model valves, each with a slightly different length than the originals, also induced shaft-mount valvetrain geometry issues. Going the exotic route, Jesel and T&D will make custom rocker arms and shaft systems to order-for a price.

The same Comp 10-degree retainer (PN 1795) works with both new valves. However, the new intake (left) has 4.72-inch-long x 8mm stems and uses bead-lock keys (PN 632). The new exhaust (right) has a 4.71-inch-long x 11/32-inch stem machined for standard multigroove locks (PN 612). Mixing and matching valvetrain parts like this is not unusual when adopting late parts to old niche motors.

The same Comp 10-degree retainer (PN 1795) works with both new valves. However, the new intake (left) has 4.72-inch-long x 8mm stems and uses bead-lock keys (PN 632). The new exhaust (right) has a 4.71-inch-long x 11/32-inch stem machined for standard multigroove locks (PN 612). Mixing and matching valvetrain parts like this is not unusual when adopting late parts to old niche motors.

Nelson came up with a more affordable solution: Machine a 6061-T6 extruded aluminum plate to accept Chevy-style independent rocker arm studs, then mount it on the Buick head using the stock rocker shaft mounting holes. This permits using a wide variety of aftermarket rocker arms-even stock svy stamped-steel ones-and installing Comp full roller rockers as Nelson did offers a significant friction reduction. Inexpensive, hollow Chevy pushrods oil the valvetrain, and even at 5/16 inch od, they're stiffer and lighter than the original wimp 1/4-inch Buick solid pushrods. The custom rocker plates fit 215, 300, and 340 Buicks; Nelson plans to sell them to the public (contact Joe Sherman Racing). Careful measurement, jigs, gauges, and a Bridgeport mill would be needed to do a similar conversion for you own niche engine.

Even though the Buick's valve stem lengths are short, its installed spring height is actually taller than a standard small-block Chevy; installing Comp beehive springs (PN 26918) required shimming the intake and exhaust spring pockets 0.060 and 0.030 inch, respectively, to develop a 1.75-inch installed height. For details on how to select and fit springs on any engine, see "All About Valvesprings" (Nov. '10).

Air, Fuel, Spark

Most niche engines need induction-side help. One source for performance intakes for many oddball engines is Offenhauser. Sometimes you can also adapt a manifold from a modern engine with similar port layout and length by fabricating transitional adapter plates; the manifold needs to come from a shorter-deck-height engine to accommodate the plates' added thickness.

In some respects the 300/340 head was ahead of its time: The inlet shape uses an offset valve bowl with only one side open past the valveguide boss to induce mixture swirl-good down low, not so good at high lift. Nelson enlarged the bowl in key areas, streamlined the guide boss, raised the roof in the throat area, and reshaped the short-turn radius.

In some respects the 300/340 head was ahead of its time: The inlet shape uses an offset valve bowl with only one side open past the valveguide boss to induce mixture swirl-good down low, not so good at high lift. Nelson enlarged the bowl in key areas, streamlined the guide boss, raised the roof in the throat area, and reshaped the short-turn radius.

Once restricted primarily to high-end racers, the ultimate solution is a pricey, fabricated (aka sheetmetal) intake. Hogan's is one source for custom-fabbed intakes. The advantage is that a fabricated intake's runner lengths and plenum volume can be custom-tailored to the engine's rpm operating range.

Alas, Offy has no 300 Buick intake; its 215-style intake works with custom adapter plates, but the runners are too small; the later Buick 350 has a taller deck and a different port layout; and a fabbed intake was a budget breaker. Nelson instead ported the 300/340 cast-iron stocker, topping it off with a 2-inch spacer and an Edelbrock PN 1407 750-cfm carb. Sending the manifold out to Extrude Hone is another possible solution.

The exhaust manifolds can also be enlarged by Extrude Hone, but for a hot rod the preferred alternative is tuned exhaust headers. Sanderson Headers actually offers universal shorty Buick 300/340 headers. If no shelf headers are offered, there are numerous custom header fabricators. If you want to make your own headers, sometimes a header set from an engine with a similar exhaust port layout can serve as a basis. For example, some 472/500 Cadillac guys have reworked big-block Chevy headers to fit, replacing the big-block flange with a Caddy flange. Headers By Ed is one source for a variety of flanges, pipes, and bends for do-it-yourself fabricators.

Ignition improvements will also be needed to reliably fire a high-output engine. No one uses points anymore. Sometimes an electronic distributor from a later engine will fit. For example, the Buick 215, 300, 340, and 350 all have the same distributor dimensions, so you could install a late GM Buick 350 HEI, or even an MSD Pro Billet distributor (PN 8548). Failing that (or to maintain an original outward appearance), Mallory, PerTronix, and now MSD offer electronic conversion kits for just about any existing distributor. Ultimately you can adopt a distributorless coil-ignition system from a late-model engine. MSD offers a stand-alone box for controlling GM LS engine coils.

Oiling Upgrade

With a coil ignition, you'll still need a dummy shaft or gutted distributor housing to drive a conventional oil pump. At the high end, you could eliminate the entire conventional oil pump and wet-sump pan by going to a custom dry-sump oiling system. A vacuum pump and crankcase evacuation system permit super-low-drag rings for even more power. Yet another trick is thin synthetic oil that reduces rotating drag.

Aardema has done SOHC conversions by building custom cam boxes that bolt to an existing overhead-valve motor's heads. On this LS motor, converting from OHV to SOHC configuration was worth 21 hp with an identical cam profile-and the engine happily revs to 7,000 rpm with no valve float.

Aardema has done SOHC conversions by building custom cam boxes that bolt to an existing overhead-valve motor's heads. On this LS motor, converting from OHV to SOHC configuration was worth 21 hp with an identical cam profile-and the engine happily revs to 7,000 rpm with no valve float.

In a more practical vein, most of us will retain a wet-sump setup, but enhanced for greater reliability. The Buick, for example, has notoriously bad oiling, due to all the right-angle turns into and out of the front-cover-mounted oil pump. Nelson replaced the original front cover with a Silver Seal front cover and high-volume oil pump listed for the later 3.8L Buick V6. A relief spring for this pump was selected to provide 50 to 60 psi max with 10W-30 oil. In a pinch, you can shim your existing stock pump's relief spring. A rough rule of thumb is that you want at least 15 psi at idle, and an additional 10 psi for every 1,000 engine rpm up to 60 psi max. For higher-end engines, consider making your own crank scrapers and windage trays to reduce windage losses.

The stock 300 pan cleared the crank. Oil pickups from a Buick 350 or 3.8L V6 work. Late versions of the V6 have larger-diameter tubes, but the block mounting hole diameter must be correspondingly increased. Any later pickup must be for a 5.25-inch-deep pan to be compatible with the 300's pan. For those needing a custom-built oil pan or even a complete dry-sump system, Billet Fabrication is one source.

Endgame

Is all this effort worth it? Behold the Buick's metamorphosis: The highest-rated, 10.25:1, 300/four-barrel factory combo supposedly made 250 hp at 4,800 rpm and 335 lb-ft at 3,000 rpm. The 340 made about 10 hp more, and even the best Buick 350 was only good for 280 hp stock.

Installed in Aardema's '34 Ford Roadster, this Arias aluminum 427 big-block Chevy-based engine runs 5.3L Porsche 928 V8 DOHC heads. The block was special-ordered with slightly relocated bores and the Porsche head bolt pattern. DOHC swaps like these require a fabricated intake like the one here.

Installed in Aardema's '34 Ford Roadster, this Arias aluminum 427 big-block Chevy-based engine runs 5.3L Porsche 928 V8 DOHC heads. The block was special-ordered with slightly relocated bores and the Porsche head bolt pattern. DOHC swaps like these require a fabricated intake like the one here.

But Nelson's 349? Running 91-octane gas on Joe Sherman's SuperFlow dyno, the engine ran best with just 30 degrees total timing, a tribute to the Buick's combustion chamber efficiency. Using large-tube Miller custom headers, the engine made 390.6 hp at 5,700 rpm. More than 1 hp/ci was produced from 4,400 through 6,000 rpm, the highest rpm point tested. Torque was a healthy 422.4 lb-ft at 3,700. In fact, torque from 3,300 rpm (the lowest rpm test point) through 4,800 was in excess of 400 lb-ft.

It's been said that "an engine doesn't care what name is on its valve covers." The basics for making power are well known and proven; the trick is implementing general theory in a build. Hot rodding a niche engine takes a considerable amount of skill, effort, and fabrication, but with a little perseverance, the end result is a unique combo that makes decent power in its own right.

Exotic Heads

Pete Aardema specializes in what could be the ultimate dare to be different, street-driven head conversion: changing American domestic pushrod engines to overhead cam configurations. The two main approaches used by Aardema: for single overhead cam (SOHC) conversions, fabricating a custom cam box that bolts to the existing pushrod-type head; for dual overhead cam (DOHC) changeovers, bolting on a DOHC head from a foreign engine.

The chamber spacing on a Nissan DOHC head off an Infiniti or Titan V8 is within 0.009 inch of a Chevy small-block (both classic and LS). It may fit the LS even better because both have four head bolts/cylinder. Most engines tolerate a 0.010- to 0.020-inch misalignment, but to end up dead on, offset-bore the block.

The chamber spacing on a Nissan DOHC head off an Infiniti or Titan V8 is within 0.009 inch of a Chevy small-block (both classic and LS). It may fit the LS even better because both have four head bolts/cylinder. Most engines tolerate a 0.010- to 0.020-inch misalignment, but to end up dead on, offset-bore the block.

For a DOHC conversion, the idea is to adapt a head from an engine family that has similar cylinder bore spacing to the pushrod engine you're working on. A Nissan Infiniti V8 is close to a small-block Chevy; a six-cylinder Subaru, a 4.3L Chevy 90-degree V6; a V8 Porsche, a big-block Chevy. Scope out swap possibilities by comparing head gaskets from different engines. It helps if the head bolt patterns are similar, but don't be afraid to plug and redrill head bolt and coolant holes in the block. Aftermarket blocks (say, from Dart) can be ordered with an undrilled blank deck and the bore centers only roughed in. Cometic can make custom head gaskets to order.

Provisions must be made to supply oil to the new head and block off the old, now-unneeded passages. This may require lifter-bore plugs-either completely blank (fabricate external oil lines), drilled to supply necessary internal oil to the top end, or so modified to keep the bottom end alive.

Paxton offers a universal airbox assembly for carbs, as on this small-block Mopar kit. A new, more compact, round airbox is also offered. The airbox plus aircraft-style flexible ducting (sold by Aircraft Spruce) could be used to fab a kit for a niche motor. Aircraft Spruce also sells aluminum plate to make custom mounting brackets.

Paxton offers a universal airbox assembly for carbs, as on this small-block Mopar kit. A new, more compact, round airbox is also offered. The airbox plus aircraft-style flexible ducting (sold by Aircraft Spruce) could be used to fab a kit for a niche motor. Aircraft Spruce also sells aluminum plate to make custom mounting brackets.

Most modern DOHC mills are beltdriven. You can often adapt or modify the original drive pulleys with custom idlers and different-length belts, or use a Gilmore setup with cogged pulleys. ASP is one source for special pulleys. Custom cams are available for any application these days, although they may need to be made from billet steel. And yes, Aardema is willing to offer advice and assistance to those attempting similar conversions.

Power-Adders

If all this fabrication and adoption just looks like way too much effort, there's an additional tried-and-true path toward more power: Add a supercharger, turbocharger, or nitrous oxide system. Probably the easiest power-adder to adapt is a universal plate nitrous oxide system that fits under the carb. Moving up the food chain, there may not be a ready-made supercharger kit for your engine. If that's the case, for the Roots (GMC) blower, you'll need a custom intake and drive setup; big blower specialty shops such as BDS can, on a special-order basis, machine custom drives and pulleys as well as modify existing standard intake manifolds to fit. A centrifugal supercharger is another alternative. You'll have to figure out how to mount a centrifugal on the front of the engine, but at least a special intake isn't needed. Universal sealed carb airboxes are available from Paxton. Turbocharging is the most advanced power-adder. Proper sizing is critical, and be prepared to do a lot of fabrication.