There are a lot of reasons to consider building a fresh engine. Sometimes the need arises from practical considerations, such as replacing a powerplant that is just plain tired and worn-out. Sometimes the motivation may be the search for more power or larger displacement-both worthy goals in our book. In the case of the stroker LS2 featured here, the reason for its existence was simply because the previous engine just never lived up to expectations.

Steve Smith found himself in this situation with the 407ci LS Chevy engine in his '02 C5 Z06 Corvette. Looking to increase the already potent power of the factory LS6-equipped supercar, the engine was replaced with what looked like a very promising combination based on a bigger-bore LS2 block, coupled with a 4.00-inch stroke crankshaft. This 402 combination featured power parts that really emphasized top end output, with large-ported LS7 cylinder heads, and a long duration camshaft well into the 250s (at .050 inch). Sure these parts can be optimized for a big number up top, but Smith, a high-performance driving instructor, definitely favors crisp throttle response and a fatter power curve with instant torque off the corners. This car was never intended to be a high-rpm dragstrip machine. In fact, the car's application is primarily aimed at the street, where the engine just seemed to fall short. As Smith described it, he felt like he needed to call ahead to the engine room every time he wanted to nail the throttle.

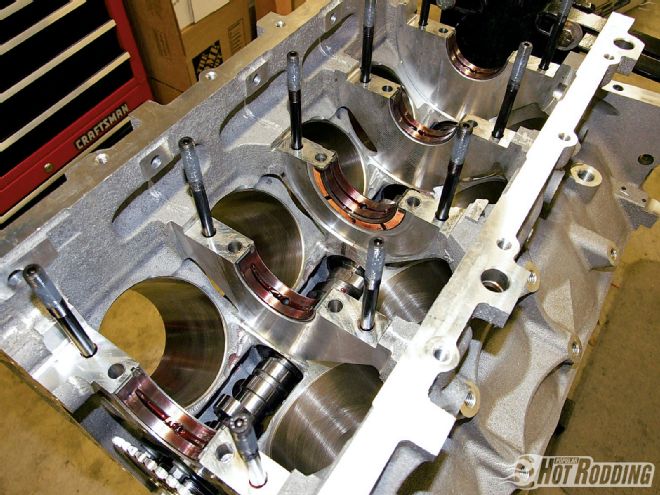

This build is based on a new factory LS2 block, which was machined slightly oversized. The block was detailed by fully blending all the oil gallery junctions, clearancing for the 4.00-inch stroke crank, and tapping for earlier LS6-style knock sensors.

This build is based on a new factory LS2 block, which was machined slightly oversized. The block was detailed by fully blending all the oil gallery junctions, clearancing for the 4.00-inch stroke crank, and tapping for earlier LS6-style knock sensors.

The final irony of the situation was that the cam and valvetrain in the original combination simply did not deliver the stability needed to pull high rpm. The bottom line was the engine was soft down low, intractable on the street, and then fell over just when it was supposed to get good, showing a maximum of 480-490 hp on the chassis dyno. To remedy the situation, Smith enlisted the aid of Tony Mamo for a new bullet, a man known in LS circles for stout performance combinations, and the chief cylinder head designer at Air Flow Research. The build goals were to create an engine combination that would improve the driveability, bottom end, and responsiveness. We'll cut to the punch line and say that the engine proved to do all that and more. The kicker here is it cranks far more top end power than the old engine, punching out a solid 540 hp at the rear wheels.

Clevite H-Series bearings were used in the main saddles, with the bearing clearance already checked to provide .0018-inch running clearance. ARP studs are the fasteners of choice, ensuring the factory main caps are clamped tight.

Clevite H-Series bearings were used in the main saddles, with the bearing clearance already checked to provide .0018-inch running clearance. ARP studs are the fasteners of choice, ensuring the factory main caps are clamped tight.

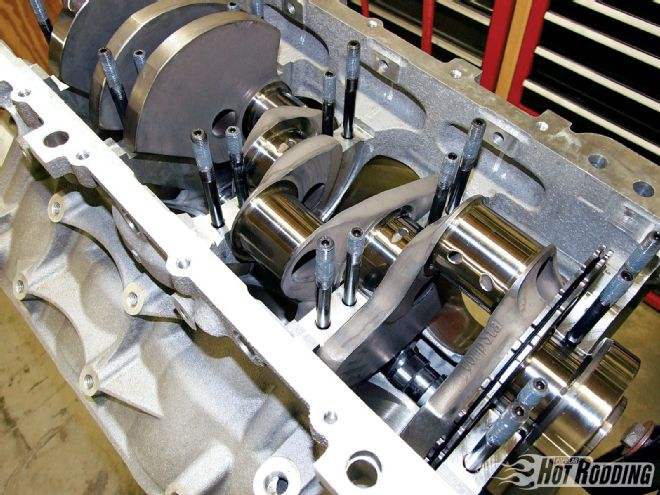

The Build The original engine was sold off in parts, and Mamo started with a fresh LS2 block as the foundation for the replacement. LS2s come at a 4.0007 bore as OEM, and Mamo will normally have the block honed to 4.005 inches with a torque plate, but in this case Smith had already ordered the pistons at 4.022 inches in anticipation of freshening the old engine. The pistons are top-of-the-line Wiseco forgings cut for their GFX 1.2, 1.2, 3mm ring package, which is an outstanding setup in terms of low drag and sealing. The bores in the fresh block were machined to match the pistons, and then Mamo followed with a complete detailed prep, including full custom porting and radiusing of the oil gallery junctions, and clearancing for the longer-stroke Callies Compstar crankshaft. The crank features 2.00-inch journals, with the reduced size cutting down the bearing speed and providing more stroke clearance in the crankcase. The rods are Callies H-beam Compstar units, at 6.125 inches center-to-center length.

Tony Mamo selected a Callies Compstar crankshaft featuring reduced diameter 2.00-inch rod journals instead of the factory 2.100-inch dimension. The smaller journal increases clearance with the longer stroke, and reduces bearing speed and frictional losses. Mamo says it is a "win-win."

Tony Mamo selected a Callies Compstar crankshaft featuring reduced diameter 2.00-inch rod journals instead of the factory 2.100-inch dimension. The smaller journal increases clearance with the longer stroke, and reduces bearing speed and frictional losses. Mamo says it is a "win-win."

Looking for improved driveability, the camshaft selection played an important role in the final characteristics of this engine. COMP ground the custom hydraulic roller 'shaft at 242 degrees duration, a specification more than 10 degrees shorter than the cam in the previous engine. The cam was cut with 114 degrees of lobe separation, and it provides .610-inch lift via a set of Terra Yella Ultralite 1.7:1 ratio rockers. Mamo installed the Cloyes timing set to park the camshaft at 111 degrees, intake centerline angle. The combination provides ample lift to tap into the flow potential of the cylinder heads, while the moderate duration and wide separation help keep things tame enough for a street performance application.

Obviously, cylinder heads are a major factor in any engine package, but it is an unusual circumstance for the very designer of the cylinder head to also play the role of the engine builder. Under development at AFR at the time this project was initiated was an all-new LS cylinder head from AFR, the AFR 215 LSx. In fact, the head was being specifically designed for 400-inch LS engines for high-output street applications, where the added displacement of the popular LS2 strokers could use the increased port volume the new head delivers as compared to the 205cc version. With a perfectly targeted cylinder head in the works, the final build was put on hold until the 225 was put into production. These cylinder heads are manufactured with the goal of maximizing flow while preserving port velocity, and with 320 cfm raging through just 215cc of intake port at only .600-inch lift, the efficiency is all there to provide huge torque and still make the power up top. Like all of AFR's modern cylinder heads, the 215 LSx is set up with components that are lightweight and functional while proven reliable in high-rpm applications, including the combination of valves, springs, retainers, and locks.

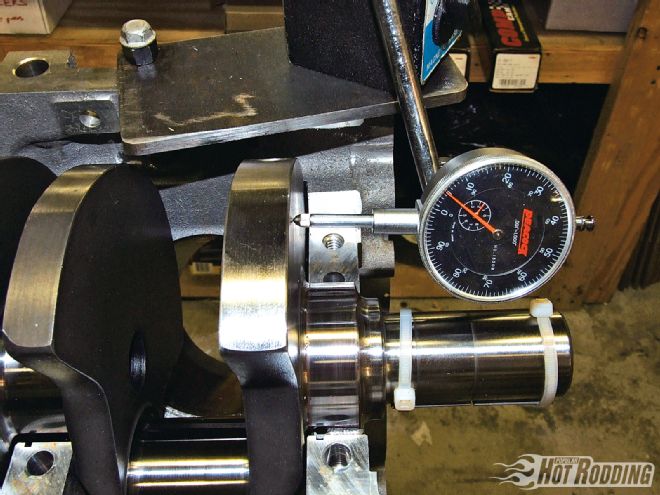

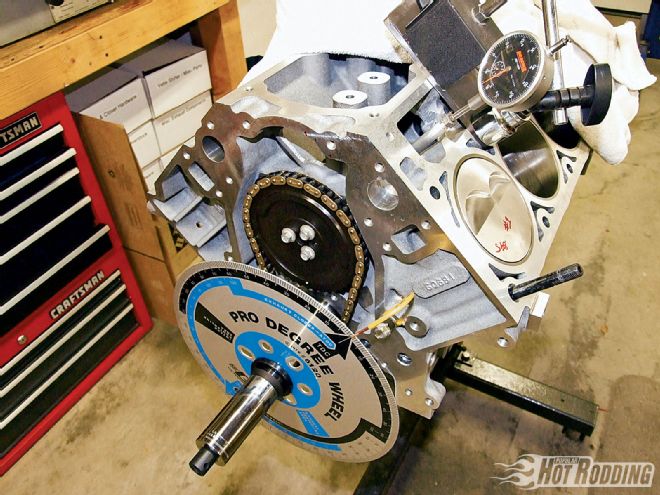

Everything in a build like this is precision measured during mock-up assembly, and then checked again during the final build. Here the crank is set up to check the thrust clearance, which indicates right at .005 inch.

Everything in a build like this is precision measured during mock-up assembly, and then checked again during the final build. Here the crank is set up to check the thrust clearance, which indicates right at .005 inch.

Topping the cylinder heads is a FAST 92 intake manifold, which was fully ported by Mamo. For street use, a factory LS2 throttle-by-wire throttle body was also prepped by Mamo with the full porting treatment, but for dyno testing purposes, the engine was equipped with a 90mm Nick Williams mechanical-linkage throttle body. The engine assembly was finished off with the American Racing 1.875-inch primary, 3-inch merge collector headers that run in the car.

With the 2.00-inch journal crankshaft and the compact Callies cap-screw rods, there is much less crankcase interference with a stroker crank. Note the very minor clearance notches necessary at the bottom of the bores.

With the 2.00-inch journal crankshaft and the compact Callies cap-screw rods, there is much less crankcase interference with a stroker crank. Note the very minor clearance notches necessary at the bottom of the bores.

Proving The Point To evaluate the effort, the completed engine was taken to Westech Performance Group's dyno test facility for the power numbers. Now, let's consider the circumstances. The previous LS7-style combination was pulled and sold off in parts to make way for this new engine at essentially the same displacement in the hope of better performance; you'd better believe that the heat was on as far as delivering the goods. Anticipation was pretty high as the engine was fired and taken through the break-in procedure. The well-established dyno protocols and procedures were carefully followed by the Westech crew in setting the base calibrations to the fuel and ignition systems prior to making the full dyno runs. There was no questioning the engine was exhibiting tamer characteristics than the old combination, as it idled on the dyno with a mild lope and 12 inches of vacuum. The promise of driveability seemed to be there.

It wasn't until the handle was pulled on full dyno sweeps that we had a complete picture of just how well this engine performs. A fat torque curve was one of the build criteria, but the graph showed that this engine was downright obese, pulling over 500 lb-ft from 3,900-6,400 rpm, while peaking at 564 lb-ft from 4,900-5,200 rpm. Along with the huge torque numbers, the engine was an animal, as the tach swung to the high side of 6,000, recording a peak power reading of 618 hp at 6,300 rpm, and continuing to pull with enthusiasm past peak to 6,800 rpm. As the numbers indicated, the engine certainly met their mark, and then some.

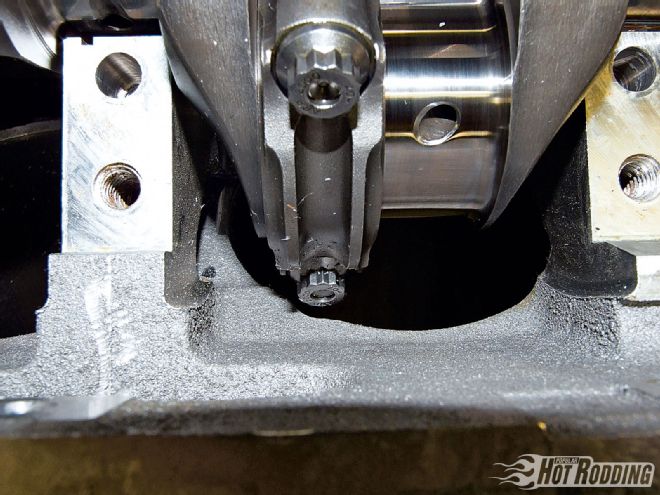

Mamo used a factory windage tray, which needs to be spaced for clearance with the longer crankshaft stroke. The bottom end was finished off with a factory "batwing" Corvette cast-aluminum oil pan.

Mamo used a factory windage tray, which needs to be spaced for clearance with the longer crankshaft stroke. The bottom end was finished off with a factory "batwing" Corvette cast-aluminum oil pan.

While the engine dyno numbers validated the effort, as a final note, the engine has been installed in the Z06, and it delivers exactly as intended. According to follow-up chassis dyno numbers, the new combination belts out a staggering 80 lb-ft advantage compared to the old engine, and as noted earlier, it has over 50 more horsepower at the top. Smith says the difference in the car feels like going from a small-block to a 454, with torque that comes on right now, but with power that keeps pulling as long as you've got the nerve to peg the throttle to the wall.

The COMP hydraulic roller is a custom single pattern, with 242 degrees duration at .050 and a lobe separation angle of 114 degrees. The cam was installed with an intake centerline angle of 111 degrees, or 3 degrees advanced.

DYNO DATA

RPM

TQ

HP

3,600

485

332

3,800

498

360

4,000

519

395

4,200

540

432

4,400

552

463

4,600

558

489

4,800

564

515

5,000

564

537

5,200

564

558

5,400

560

576

5,600

553

590

5,800

545

602

6,000

545

611

6,200

522

616

6,300

515

618

6,400

506

617

6,600

487

612

6,800

463

599

BY THE NUMBERS

407ci LS Chevy

Block:

LS2, overbored

Bore:

4.022 inches

Stroke:

4.00 inches

Displacement:

407 ci

Compression ratio:

11.5:1

Crank & rods:

Callies Compstar

Camshaft:

COMP Cams hydraulic roller

Timing chain:

Cloyes

Lifters:

Crane Billet

Pushrods:

COMP Cams 7.500

(5/16-inch diameter)

Springs:

AFR 8019

Installed height:

1.770

Spring load closed:

160 pounds on the seat

Spring load open:

410 pounds at 1.160

Retainers:

AFR 7-degree Titanium

Valve locks:

AFR 7-degree beadlock

Cam duration, intake:

242 at .050

Intake lift:

.610 inch

Cam duration, exhaust:

242 at .050

Exhaust lift:

.610 inch

Rocker arms:

Yella Terra Ultralite

Rocker ratio:

1.7/1.7:1

Lobe separation:

114 degrees

Installed centerline:

111 degrees

Ring pack:

Wiseco GFx 1.2/1.2/3mm oil

Ring end gap:

.018 top/.022 second

Pistons:

Wiseco forgings with coated skirts

(.004-inch piston-to-wall)

Main studs:

ARP

Rods:

Callies Compstar 6.125-inch H-beam

Main bearings:

Clevite H

Rod bearings:

Clevite HN

Main journal diameter:

OEM

Rod journal diameter:

2-inch journal

Main clearance:

.0018 inch

Rod clearance:

.0021 inch

Cylinder heads:

AFR 215 LSx

Head bolts:

ARP studs

Intake manifold:

FAST 92

Ported by Tony Mamo

Intake flow:

320 cfm at .600

Exhaust flow:

254 cfm at .600

Intake valve:

REV stainless 2.040 inches

Exhaust valve:

REV stainless 1.600 inches

Head gaskets:

Fel-Pro 1041 (.041 inch)

Piston/head clearance:

.030 inch

Engine gaskets:

OEM

Throttle body:

90mm Nick Williams

Headers:

American Racing 1.875 inches

with 3-inch merge collector

Ignition:

OEM

Spark plug wires:

OEM

Damper:

ATI with 10 percent U/D

steel hub with aluminum shell

Water pump:

Meziere electric

Oil pan:

stock LS1/LS6 ("batwing" pan)

Oil pump:

stock ported by Mamo

Oil:

AMSOIL 5W-30

Oil filter:

Fram

The COMP hydraulic roller is a custom single pattern, with 242 degrees duration at .050 and a lobe separation angle of 114 degrees. The cam was installed with an intake centerline angle of 111 degrees, or 3 degrees advanced.

DYNO DATA

RPM

TQ

HP

3,600

485

332

3,800

498

360

4,000

519

395

4,200

540

432

4,400

552

463

4,600

558

489

4,800

564

515

5,000

564

537

5,200

564

558

5,400

560

576

5,600

553

590

5,800

545

602

6,000

545

611

6,200

522

616

6,300

515

618

6,400

506

617

6,600

487

612

6,800

463

599

BY THE NUMBERS

407ci LS Chevy

Block:

LS2, overbored

Bore:

4.022 inches

Stroke:

4.00 inches

Displacement:

407 ci

Compression ratio:

11.5:1

Crank & rods:

Callies Compstar

Camshaft:

COMP Cams hydraulic roller

Timing chain:

Cloyes

Lifters:

Crane Billet

Pushrods:

COMP Cams 7.500

(5/16-inch diameter)

Springs:

AFR 8019

Installed height:

1.770

Spring load closed:

160 pounds on the seat

Spring load open:

410 pounds at 1.160

Retainers:

AFR 7-degree Titanium

Valve locks:

AFR 7-degree beadlock

Cam duration, intake:

242 at .050

Intake lift:

.610 inch

Cam duration, exhaust:

242 at .050

Exhaust lift:

.610 inch

Rocker arms:

Yella Terra Ultralite

Rocker ratio:

1.7/1.7:1

Lobe separation:

114 degrees

Installed centerline:

111 degrees

Ring pack:

Wiseco GFx 1.2/1.2/3mm oil

Ring end gap:

.018 top/.022 second

Pistons:

Wiseco forgings with coated skirts

(.004-inch piston-to-wall)

Main studs:

ARP

Rods:

Callies Compstar 6.125-inch H-beam

Main bearings:

Clevite H

Rod bearings:

Clevite HN

Main journal diameter:

OEM

Rod journal diameter:

2-inch journal

Main clearance:

.0018 inch

Rod clearance:

.0021 inch

Cylinder heads:

AFR 215 LSx

Head bolts:

ARP studs

Intake manifold:

FAST 92

Ported by Tony Mamo

Intake flow:

320 cfm at .600

Exhaust flow:

254 cfm at .600

Intake valve:

REV stainless 2.040 inches

Exhaust valve:

REV stainless 1.600 inches

Head gaskets:

Fel-Pro 1041 (.041 inch)

Piston/head clearance:

.030 inch

Engine gaskets:

OEM

Throttle body:

90mm Nick Williams

Headers:

American Racing 1.875 inches

with 3-inch merge collector

Ignition:

OEM

Spark plug wires:

OEM

Damper:

ATI with 10 percent U/D

steel hub with aluminum shell

Water pump:

Meziere electric

Oil pan:

stock LS1/LS6 ("batwing" pan)

Oil pump:

stock ported by Mamo

Oil:

AMSOIL 5W-30

Oil filter:

Fram