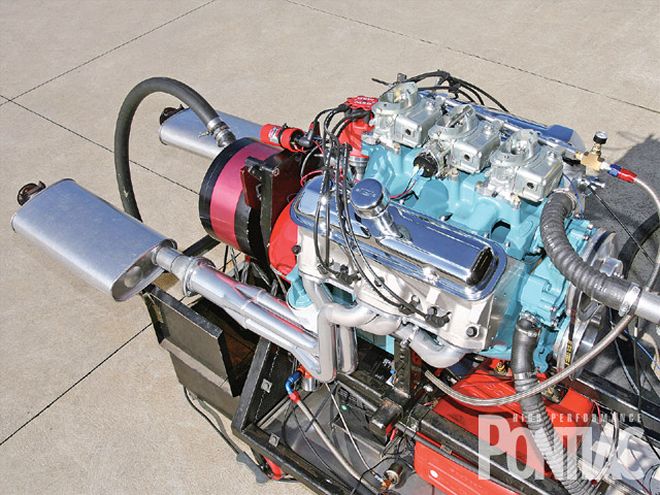

This Weber Racing Equipment-built 389-based, 449-cube Tri-Power engine retains the Pontiac heritage while putting out substantially more horsepower than stock.

This Weber Racing Equipment-built 389-based, 449-cube Tri-Power engine retains the Pontiac heritage while putting out substantially more horsepower than stock.

You can say what you will about the 400 Ram Air IIIs, Ram Air IVs, 455 H.O.s, and Super-Dutys, but they owe their very existence to the tried-and-true 389. Introduced in the '59 model year, this versatile V-8 boasted horsepower from 215 in economy trim up to 345 in Tri-Power form.

Power levels continued to increase over the years, culminating in a peak of 360 in the '65-'66 GTOs. They were responsive and flexible, building enough torque to move a 3,600-pound Goat around with authority, yet they could be docile enough for trips to the grocery store. It was an ideal situation for street-performance enthusiasts because in the relatively light GTO body, the 389 engine really shined.

History

When it came time for Barry Penfound, of Penfound Design, to choose a powerplant for "Sabertooth," his '64 Pro-Touring GTO project, he didn't look any further than the engine bay. You guessed it-the original 389 was still there. As with the rest of the Goat, Barry's goal was to provide modern levels of performance yet retain its signature personality.

Engine-builder Dave Weber torques the rod caps down. He has been involved with Pontiacs since the Super-Duty days and built Ram Air V engines for Ray Faro back in the early '70s.

Engine-builder Dave Weber torques the rod caps down. He has been involved with Pontiacs since the Super-Duty days and built Ram Air V engines for Ray Faro back in the early '70s.

Students of the Pontiac V-8 know that while the 389 was a great engine for its time, the introduction of the 400 in 1967 also brought several design changes that significantly improved performance. Most notable were in the cylinder heads and induction system. The D-port heads were redesigned with larger valves and better ports, complemented by a four-barrel intake manifold that was actually a street version of the Super-Duty NASCAR intake. Still, enthusiasts loved the Tri-Power system, and many '67 GTOs were retrofitted with the earlier intake even though its effect on performance was debatable.

The Plan

To marry vintage flavor to modern technology and increase power at the same time, Barry turned to Bryan Weber of Weber Racing Equipment in North Ridgeville, Ohio, who formed a plan that put the goals within practical reach, and his dad, Dave, assembled the engine.

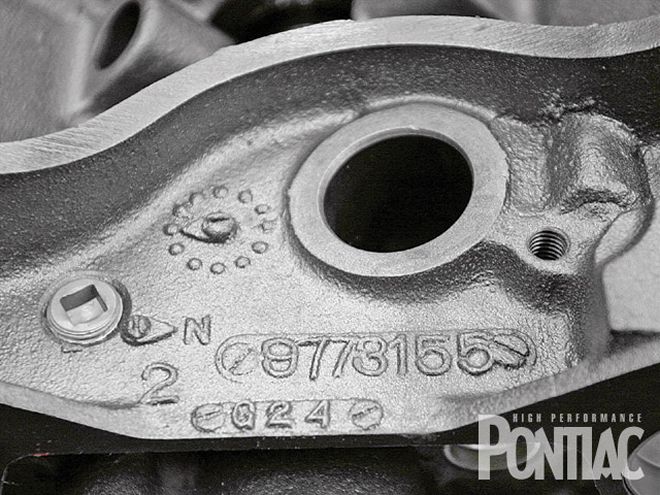

The casting number and date indicate this is a late-production '64 389, which was cast during the July 2, 1964, night shift. The block code is 78X, making it an original four-barrel GTO engine, the one the car was built with.

The casting number and date indicate this is a late-production '64 389, which was cast during the July 2, 1964, night shift. The block code is 78X, making it an original four-barrel GTO engine, the one the car was built with.

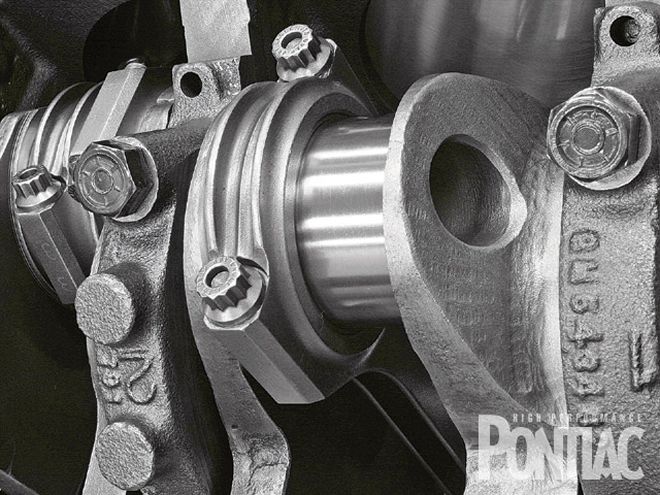

Bryan felt the original 389 block was more than up to the task. First came a dose of displacement by increasing the bore from 4.06 to 4.10 inches and the stroke from 3.75 to 4.25 inches, resulting in 449 cubes. Bryan says, "The long stroke adds a healthy amount of torque, while the 0.040-inch overbore allows for plenty of cylinder-wall thickness. This combo did, however, require custom pistons." The block was filled with a 4.25-inch Eagle cast-steel crankshaft, a set of 6.800-inch Eagle forged rods, and custom 0.040-over Wiseco pistons.

To make the most of all those cubes, more airflow was required. Sure, the original 716s could be ported and polished, but even then they still won't be able to keep up with more modern heads. Additionally, the GTO is going to be a real corner carver, so any weight savings off the nose will benefit handling. To those causes, a set of ported Edelbrock heads greatly increased flow and saved more than 50 pounds off the front end.

Camshaft technology has made such huge gains over the last several years that it seemed silly to ignore the power waiting to be grabbed by going with a modern design. Utilizing a hydraulic roller over a flat-tappet would further aid efficiency by lowering frictional losses.

A cast 4.25-inch Eagle crank features 3.00-inch mains and 2.20-inch rod journals. The rotating assembly was internally balanced by Weber Racing Equipment.

A cast 4.25-inch Eagle crank features 3.00-inch mains and 2.20-inch rod journals. The rotating assembly was internally balanced by Weber Racing Equipment.

Weber went with a Comp Cams Xtreme Energy profile with 236/242 degrees of duration at 0.050-inch lift, 0.520/0.540-inch lift when coupled with Crane 1.50:1-ratio roller rockers. Lobe separation is 110 degrees. Admittedly the grind is a little on the radical side, but the additional displacement tames it down quite a bit.

Weight was reduced, and airflow was improved yet again via the addition of a Barry Grant Six Shooter induction system. With three BG two-barrel carbs, each flowing 250 cfm, on a redesigned high-flow aluminum intake manifold, the Tri-Power mystique was preserved, yet modernized. The end result is an engine that still retains the look and attitude that made the GTO famous and produces power far beyond factory levels.

Follow along as Weber Racing builds a 21st century Tri-Power Pontiac with due respect to Pontiac's performance heritage. Next month, we'll start it up, break it in, and put this beast on the dyno to see how much power it makes.