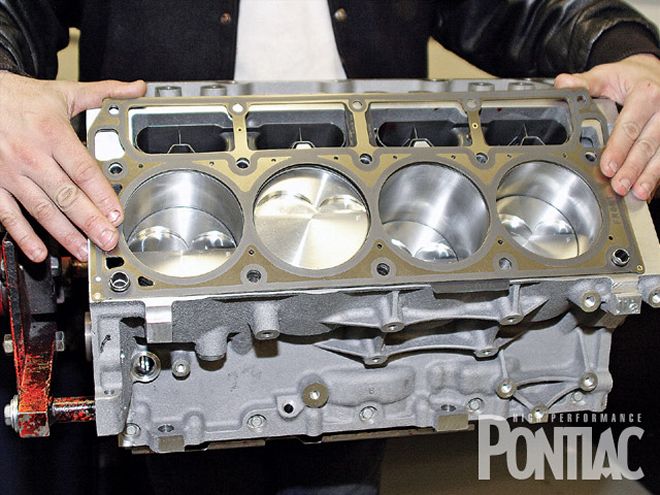

With the majority of the short-block assembled in Part I, the L92/LS3 engine is ready to be completed and then tested on the dyno. To recap the build, in Part I Texas Speed and Performance (TSP) used a brand-new GM 6.2L aluminum L92/LS3 block as the foundation to build a 418ci engine. TSP utilized the services of Sunset Racecraft in Lubbock, Texas, to bore the block to 4.080 inches (4.065-inch bore is stock) and then install a custom Eagle 4.00-inch stroker crankshaft, Eagle connecting rods, and Diamond Racing pistons. Texas Speed completed the buildup with its own Texas Speed/Precision Race Components (PRC)-prepped cylinder heads and accessories.

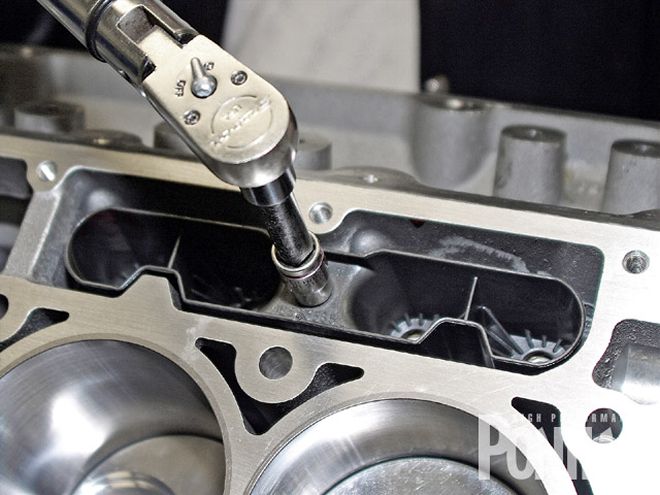

With the short-block completed, attention turns to the cylinder heads and valvetrain. New GM lifter trays are utilized along with GM LS7 hydraulic roller lifters. After lubricating the housing and roller portion of the lifter with assembly lube, they're pushed into the tray, all four trays are fitted into the block, and the single 10mm bolt that retains each one is torqued to specification. Although the Gen IV lifter trays are similar to the original Gen III design, the Gen IV's enhanced bay-to-bay breathing architecture necessitated a redesign.

With the short-block completed, attention turns to the cylinder heads and valvetrain. New GM lifter trays are utilized along with GM LS7 hydraulic roller lifters. After lubricating the housing and roller portion of the lifter with assembly lube, they're pushed into the tray, all four trays are fitted into the block, and the single 10mm bolt that retains each one is torqued to specification. Although the Gen IV lifter trays are similar to the original Gen III design, the Gen IV's enhanced bay-to-bay breathing architecture necessitated a redesign.

According to Trevor Doelling, co-owner of TSP with Jason Mangum, "The key to the power potential of the 418 lies in a blueprinted short-block that has undergone extensive development and testing before it reaches the market. Working in conjunction with the manufacturers and Sunset Racecraft, we developed engine packages that offer value and performance. For enthusiasts with an LS engine with a bore of 4.00 or greater, the factory L92/LS3 head can be utilized and flows almost 320 cfm on the intake in stock form. By developing a five-axis CNC-porting program, we achieved a higher-flowing head that improves upon the factory velocity and provides a much more balanced intake-to-exhaust flow ratio," (66.4 percent vs. stock 59.8 percent).

Retailing at $4,095, the TSP short-block is offered in both 418 and 427ci versions (PN 25-418LS3LB or 25-427LS3LB) and is a solid foundation for a serious LS-series build. The long-block costs $7,399 (PN 25-418LS3LB or 25-427LS3LB). Follow along as we complete the assembly and dyno test the TSP 418.

Dyno Testing

All testing was completed on Sunset Racecraft's Dynamic Test Systems' (DTS) model 4000G dyno. HP Tuners VCM Suite was used to tune the computer, the timing was locked at 28 degrees, and the knock sensors were removed for testing.

VP 101-octane unleaded was utilized in the cell (TSP says 93-octane would work just as well), fed to the engine via the shop's Aeromotive fuel pump, and regulated to 58 psi. In order to ensure consistency in the test results, the various combinations were pulled after the engine had recorded 165 degrees on the test cells' DTS model S-1007M engine-cooling system. No engine-accessory belts were required since a Meziere electric water pump was utilized.

Once the engine reached temp, the dyno operator took it to 3,800 rpm and then applied a dyno load. Once loaded, the engine was slowly brought up to 3,000 rpm and pulled until the specified redline. Standardized SAE calculations were used to correct the horsepower and torque to industry standards.

The block is fitted with two new GM cylinder-head aligning dowels (PN 12570326) per bank, the block surface is wiped clean with acetone, and GM MLS LS7 head gaskets (PN 12610046; sold individually) with a bore size of 4.125 inches are placed over the dowel pins.

The block is fitted with two new GM cylinder-head aligning dowels (PN 12570326) per bank, the block surface is wiped clean with acetone, and GM MLS LS7 head gaskets (PN 12610046; sold individually) with a bore size of 4.125 inches are placed over the dowel pins.

Dyno Test Configurations

Test No. 1 - (Baseline) - Stock L92/LS3 heads, P.T.M. 92mm throttle body, SLP 85mm MAF, stock L76/L92 intake, and Comp Cams hydraulic roller camshaft with 242/248 duration at 0.050 and 0.612/0.615 lift on a 114 LSA

Test No. 2 - Replaced stock L92/LS3 heads with PRC ported L92/LS3 heads

Test No. 3 - Swapped to a Comp Cams hydraulic roller camshaft with duration of 251/259 at 0.050 and 0.660/0.603 lift on a 111 LSA, replaced SLP 85mm MAF with TSP 100mm MAF

Results:

Baseline numbers for the 418 were an outstanding 608 hp at 6,300 rpm with 561 lb-ft of torque at 5,200 rpm. At the lowest recorded rpm of 4,000, the engine was already making 487 lb-ft of torque with 371 hp. Horsepower jumped over 500 at 4,800 rpm and crested the 600 mark at 5,900 rpm through the redline of 6,500. Most impressive was the torque, which exceeded 500 lb-ft from 4,100 to 6,300 rpm. Average horsepower and torque from 4,000 to 6,500 rpm checked in at 531.5 and 532 lb-ft, respectively.

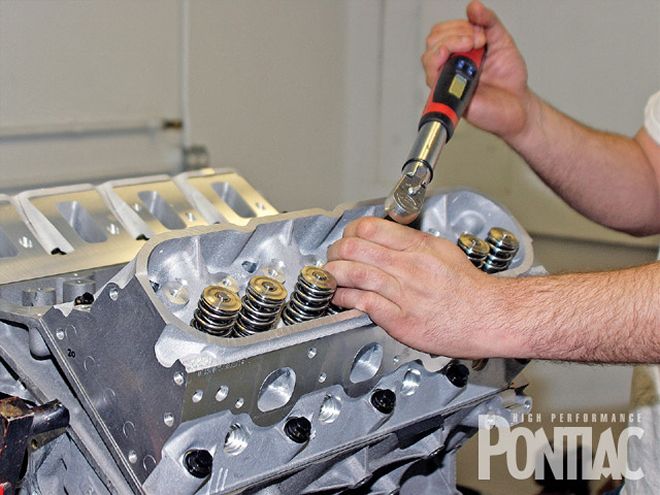

Next, the Texas Speed/Precision Race Components L92 heads (see Sidebar) are mounted over the dowels, and a set of optional ARP hex head bolts (PN 46-134-3610; retail $99.99) are lubricated and threaded in. These heads have a total of 15 head bolts with 10 larger bolts located in the center and bottom of the head and 5 bolts at the top. Head bolts 1-10 are torqued to 75 ft-lb in sequence from the center outwards, alternating sides. A second pass takes them to 85 ft-lb. The five head bolts on the surface closest to the intake valley are torqued to 23 ft-lb alternating side-to-side, working outwards. For extreme forced-induction or nitrous use, Texas Speed offers ARP's Pro-Series 12-point head studs (PN 46-234-4317, retail $247.99).

Next, the Texas Speed/Precision Race Components L92 heads (see Sidebar) are mounted over the dowels, and a set of optional ARP hex head bolts (PN 46-134-3610; retail $99.99) are lubricated and threaded in. These heads have a total of 15 head bolts with 10 larger bolts located in the center and bottom of the head and 5 bolts at the top. Head bolts 1-10 are torqued to 75 ft-lb in sequence from the center outwards, alternating sides. A second pass takes them to 85 ft-lb. The five head bolts on the surface closest to the intake valley are torqued to 23 ft-lb alternating side-to-side, working outwards. For extreme forced-induction or nitrous use, Texas Speed offers ARP's Pro-Series 12-point head studs (PN 46-234-4317, retail $247.99).

PRC's ported L92/LS3 heads paid dividends with peak horsepower of 630 at 6,400 rpm and torque of 570 lb-ft at 5,200 rpm. Horsepower and torque gains were seen across the rpm range with averages of 12 and 11.5, respectively. Horsepower at the peaks jumped by 28 but torque gains were a more modest 9 lb-ft. The real story lies in the torque gains between 5,300 and 6,500 where they started out at 10 lb-ft and ramped up to 20 lb-ft. Neither torque nor horsepower suffered at the lower end of the rpm range.

The final test was comprised of the cam upgrade and TSP's own 100mm MAF, resulting in a staggering 641.2 hp at 6,400 rpm with 578.5 lb-ft. of torque at 5,200. Average horsepower and torque rose by 6.6 and 6.3, respectively, while the peak horsepower jumped by 10.9 with torque peak gains of 8 lb-ft. Although the peak and average gains were modest, the larger cam and higher-flowing MAF started to pick up almost equal amounts of power and torque from 4,900 rpm to the redline without sacrificing low-end power.

PRC Ported Cylinder Heads

L92/LS3 heads receive porting to the combustion chamber along with the intake and exhaust ports. The "rectangular"-port L92 head is patterned after the LS7 head but unfortunately also suffers from the same exhaust-flow deficiency. A shot inside the CNC machine shows the "D"-port-style exhaust port being thoroughly massaged. Although not shown, the PRC combustion chambers are available in sizes from 72 cc to 66 cc.

For enthusiasts looking to make big power at a budget price, TSP's offerings are right on target. LS2-equipped GTOs are prime candidates for an L92/LS3 head and cam package, since the stock bore size is 4.0 as is the L76-equipped G8. The only fly in the ointment on the G8 is the AFM, which requires a compatible aftermarket camshaft or a conversion to a non-AFM valvetrain in order to reap the full benefits of the blueprinted short-block or higher-flowing heads.

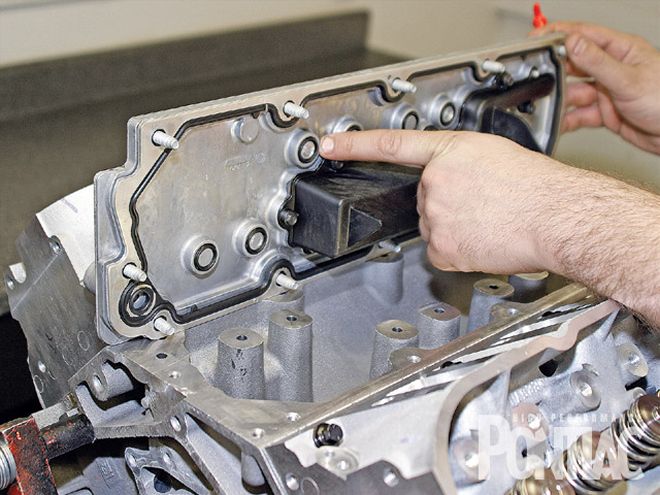

A GM LS2/LS7 valley-plate cover (PN 12570471) is used in the build rather than the L72 version that contains oiling provisions for the lifter oil-manifold assembly and active fuel-management (AFM or displacement on demand) collapsible lifters offered on the G8's L76 engine. Note the oiling provision block-off on the non-AFM-equipped valley plate.

A GM LS2/LS7 valley-plate cover (PN 12570471) is used in the build rather than the L72 version that contains oiling provisions for the lifter oil-manifold assembly and active fuel-management (AFM or displacement on demand) collapsible lifters offered on the G8's L76 engine. Note the oiling provision block-off on the non-AFM-equipped valley plate.

Owners of LS1-based Firebirds and GTOs who are looking to build big power, remember that the L92/LS3 cylinder head requires a 4.0-inch bore, and with the maximum overbore that can be achieved on an LS1/LS6 pegged at 3.905 inches, it would be more cost-effective to bolt on a set of PRC Stage 2.5 heads (HPP, Oct. '08) unless you're in the market for more cubic inches and more power potential.

Cylinder-Head Flow

All flow numbers are quoted at 28 inches test pressure. Stock LS2 and L92 cylinder-head flow numbers are from the GMPP catalog. The GMPP catalog does not list flow numbers above 0.600 lift. Ported L92 cylinder heads were tested on Precision Race Components' SuperFlow 600 flow bench.

The remaining crankshaft oil deflector (windage tray) nut is then tightened to 18 ft-lb. Note the screen in the pickup and the rigid cross-braced design.

Valve SizesIntakeExhaustValve AngleLS22.001.5515 degL92/LS32.1651.5915 degPRC L92/LS32.1651.5915 deg

High Performance {{{Pontiac}}}Engine Buildup WorksheetEngine Displacement418ciBore/Stroke4.08/4.00-inBlock/Crank ComboGM L92/LS3, bored 0.010 / {{{Eagle}}} forged 4.00-in Bore/Stroke Ratio1.02: 1Rod/Stroke Ratio1.53: 1

The remaining crankshaft oil deflector (windage tray) nut is then tightened to 18 ft-lb. Note the screen in the pickup and the rigid cross-braced design.

Valve SizesIntakeExhaustValve AngleLS22.001.5515 degL92/LS32.1651.5915 degPRC L92/LS32.1651.5915 deg

High Performance {{{Pontiac}}}Engine Buildup WorksheetEngine Displacement418ciBore/Stroke4.08/4.00-inBlock/Crank ComboGM L92/LS3, bored 0.010 / {{{Eagle}}} forged 4.00-in Bore/Stroke Ratio1.02: 1Rod/Stroke Ratio1.53: 1

Since this L92/LS3 engine was destined for a Firebird, a new F-body LS1 oil pan was employed. With a new gasket on the pan, it's placed on the bottom of the block and 14 bolts are threaded into position. The oil-pan-to-block and front-cover (front cover to be installed later) bolts are torqued to 18 ft-lb, while the oil-pan-to-rear-cover bolts are set at 106 in-lb.

Bottom EndBlock Description’07 + GM aluminum L92/LS3Deck Height9.238-inCrankEagle forged LS1, 4.00-in strokeBalancerPowerbond SFI-approvedRodsEagle forged H-beamRod Length6.125-inBearingsACL main and rod, Durabond camPistonsDiamond Racing forged aluminumPiston-to-Deck Height+0.005-inPiston PinsDiamond Racing, Trend PerformanceMethod Used to Retain Piston Pins in PistonsDouble SpiroloxRingsTotal Seal, 1.5/1.5/3.0mm, plasma-moly top, Napier second PreparationFiled-to-fit, top, 0.021-in, second 0.023-inRod Bolts/Head BoltsARP 2000 rod, ARP headBalancing Specs1,811 grams

Since this L92/LS3 engine was destined for a Firebird, a new F-body LS1 oil pan was employed. With a new gasket on the pan, it's placed on the bottom of the block and 14 bolts are threaded into position. The oil-pan-to-block and front-cover (front cover to be installed later) bolts are torqued to 18 ft-lb, while the oil-pan-to-rear-cover bolts are set at 106 in-lb.

Bottom EndBlock Description’07 + GM aluminum L92/LS3Deck Height9.238-inCrankEagle forged LS1, 4.00-in strokeBalancerPowerbond SFI-approvedRodsEagle forged H-beamRod Length6.125-inBearingsACL main and rod, Durabond camPistonsDiamond Racing forged aluminumPiston-to-Deck Height+0.005-inPiston PinsDiamond Racing, Trend PerformanceMethod Used to Retain Piston Pins in PistonsDouble SpiroloxRingsTotal Seal, 1.5/1.5/3.0mm, plasma-moly top, Napier second PreparationFiled-to-fit, top, 0.021-in, second 0.023-inRod Bolts/Head BoltsARP 2000 rod, ARP headBalancing Specs1,811 grams

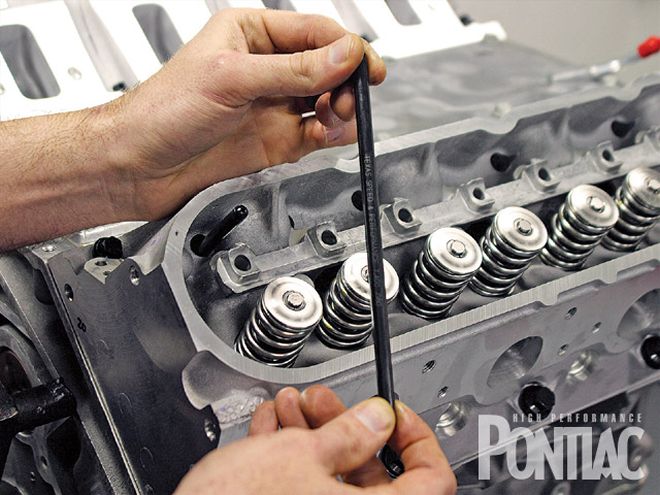

The L92/LS3 heads require a specific rocker pedestal (GM PN 12600936) due to the offset intake rocker arms (GM PN 12569167) that are used. Offset like the LS7, the L92 (1:7:1) rockers will not fit any other series of LS heads. After laying the rocker pedestal in place, a set of TSP 7.4-inch hardened 0.080 wall chromoly pushrods (PN 25-7400; retail $99.99) are slipped into position.

Oiling SystemWindage TrayGM LS1Oil PanGM ’98-’02 F-bodyOil PumpGM LS6PreparationTSP ported

HeadsCasting Number199-PRCL92ChamberOpenHead ModsFull CNC porting, five-angle CNC valve-job, clean-up milling, PRC dual valvespring kit with titanium retainers rated to 0.660-in valve liftCombustion-Chamber Volume70ccMaximum Flow at 28 Inches of Pressure356/237 cfm at 0.650 liftCompression Ratio 11.1:1Valves2.165/1.590-inAngles Used in Valve JobProprietary, five-angle CNCRetainersPRC titaniumKeepersFactory GM ValveguidesFactory GMValve SealsVitonRocker HardwareFactory GMRocker ArmsFactory GM, 1.7:1PushrodsTSP chromemoly, 5/16-inLength7.40-in

The L92/LS3 heads require a specific rocker pedestal (GM PN 12600936) due to the offset intake rocker arms (GM PN 12569167) that are used. Offset like the LS7, the L92 (1:7:1) rockers will not fit any other series of LS heads. After laying the rocker pedestal in place, a set of TSP 7.4-inch hardened 0.080 wall chromoly pushrods (PN 25-7400; retail $99.99) are slipped into position.

Oiling SystemWindage TrayGM LS1Oil PanGM ’98-’02 F-bodyOil PumpGM LS6PreparationTSP ported

HeadsCasting Number199-PRCL92ChamberOpenHead ModsFull CNC porting, five-angle CNC valve-job, clean-up milling, PRC dual valvespring kit with titanium retainers rated to 0.660-in valve liftCombustion-Chamber Volume70ccMaximum Flow at 28 Inches of Pressure356/237 cfm at 0.650 liftCompression Ratio 11.1:1Valves2.165/1.590-inAngles Used in Valve JobProprietary, five-angle CNCRetainersPRC titaniumKeepersFactory GM ValveguidesFactory GMValve SealsVitonRocker HardwareFactory GMRocker ArmsFactory GM, 1.7:1PushrodsTSP chromemoly, 5/16-inLength7.40-in

TSP utilizes a PowerBond Race Series SFI-approved 10 percent underdrive balancer pulley (PN 25-PBU1480-SS10; retail $199.99). The balancer is put over the crankshaft hub and pressed on with an LS-specific tool. Once the balancer is fully seated, a new GM crankshaft bolt is torqued to 37 ft-lb, followed by an additional 140 degrees of rotation with a torque-angle gauge.

CamBrandComp Cams hydraulic rollerDuration at 0.050251/259-degLift0.660/0.663-inCenterline108-degLobe Separation Angle111-degInstalled Position108-degLiftersGM LS7 rollerValvespringsPrecision Race Components, dualSeat Pressure140-lbsOpen Pressure{{{405}}}-lbsTiming ChainGM LS2 single-roller

InductionIntake ManifoldGM L76Throttle BodyP.T.{{{M}}}. 92mmFuel RailsGM L76Fuel InjectorsGM factory Delphi 39 lb-hrMAFTSP 100mm

TSP utilizes a PowerBond Race Series SFI-approved 10 percent underdrive balancer pulley (PN 25-PBU1480-SS10; retail $199.99). The balancer is put over the crankshaft hub and pressed on with an LS-specific tool. Once the balancer is fully seated, a new GM crankshaft bolt is torqued to 37 ft-lb, followed by an additional 140 degrees of rotation with a torque-angle gauge.

CamBrandComp Cams hydraulic rollerDuration at 0.050251/259-degLift0.660/0.663-inCenterline108-degLobe Separation Angle111-degInstalled Position108-degLiftersGM LS7 rollerValvespringsPrecision Race Components, dualSeat Pressure140-lbsOpen Pressure{{{405}}}-lbsTiming ChainGM LS2 single-roller

InductionIntake ManifoldGM L76Throttle BodyP.T.{{{M}}}. 92mmFuel RailsGM L76Fuel InjectorsGM factory Delphi 39 lb-hrMAFTSP 100mm

Next is mounting the engine onto DTS' engine dyno cradle, and installing a new flywheel and the DTS engine adapter plate. Then it's off to the dyno cell.

IgnitionEngine ControllerGM LS1Tuning SoftwareHP Tuners VCM SuiteCoilGM LS1 coil-on-plugWiresMSD 8.5mm Superconductor Plugs NGK TR-6Total Timing28-deg

ExhaustHeadersKooks 1.875-in to 2-in steppedCollectors3-in

GasketsBrandGM, MLS

Next is mounting the engine onto DTS' engine dyno cradle, and installing a new flywheel and the DTS engine adapter plate. Then it's off to the dyno cell.

IgnitionEngine ControllerGM LS1Tuning SoftwareHP Tuners VCM SuiteCoilGM LS1 coil-on-plugWiresMSD 8.5mm Superconductor Plugs NGK TR-6Total Timing28-deg

ExhaustHeadersKooks 1.875-in to 2-in steppedCollectors3-in

GasketsBrandGM, MLS

Since the computer being used for dyno test purposes is a stock 2001 LS1, which is connected to the motor via a Superior Harness aftermarket wiring harness, the fly-by-wire 90mm LS2 throttle body is replaced by a Precision Tool and Machine (P.T.M.) 92mm cable-driven throttle body (PN 25-PTM92; retail $349.99). Though sized at 92 mm, the throttle body mates to the L76's 90mm intake opening as well as the FAST LSX 92mm manifold without a problem. Trevor Doelling, Joseph Potak, and Jason Mangum (pictured left to right) of TSP work in concert to complete the wiring, throttle body cable, and coolant system in preparation for a baseline dyno run.

Since the computer being used for dyno test purposes is a stock 2001 LS1, which is connected to the motor via a Superior Harness aftermarket wiring harness, the fly-by-wire 90mm LS2 throttle body is replaced by a Precision Tool and Machine (P.T.M.) 92mm cable-driven throttle body (PN 25-PTM92; retail $349.99). Though sized at 92 mm, the throttle body mates to the L76's 90mm intake opening as well as the FAST LSX 92mm manifold without a problem. Trevor Doelling, Joseph Potak, and Jason Mangum (pictured left to right) of TSP work in concert to complete the wiring, throttle body cable, and coolant system in preparation for a baseline dyno run.

Conclusion

The latest Gen IV offerings from GM are potent performers in stock form, and when you build a bullet-proof short-block and then enhance the excellent flow of the stock L92/LS3 heads with top-notch porting and a rowdy cam, they offer phenomenal horsepower and torque output.

According to Trevor Doelling, "The redesign of the Gen IV block from the LS2 into the larger bore L92/LS3 not only increased the cubic inches of the engine, but allowed builders to offer stroker engine packages up to 427 ci without resorting to expensive cylinder liners and machine work. It's now possible to sell a top-quality 418ci or 427ci short-block or long-block at a budget price. We work with customers on a daily basis to build L92/LS3 packages that will offer over 500 hp with a mild cam and close to 675 hp for naturally aspirated race applications.

"For owners looking to make even more power, both engines are rated to take up to a 200-shot of nitrous, but we recommend a 418 over the 427 in those instances.

Since custom pistons are available to vary the stock compression from 11.1:1 down into boost friendly ratios of 8.5:1, a forced induction 418 engine can achieve over 1,000 hp. In fact, our twin-turbo street car was built for high-boost, and other than the camshaft and dished pistons, uses all of the same components as this build. If the L92/LS3 can live under the big boost and heavy boot of Jason Mangum to the tune of 1,063 rear-wheel horsepower, it shows just how robust this package is."

Whether you're looking for a race-oriented long-block for your street and strip Firebird or GTO, or simply a set of excellent flowing heads for your next project, TSP has you covered with an affordable alternative to the LS7