We've often wondered what would happen if one of the heavy hitters in racing would take a lower-level, short track race engine and apply all those neat ideas they pick up in the top areas of racing. Think about it. Most of the big factories in Detroit have hard core racing programs. We see the results in Indy Cars, road racing, drag racing and, of course, NASCAR. Imagine what would happen if one of those factories applied all that modern technology to something like a Midget engine.

Well, we don't have to imagine. In a move that caught most of the industry by surprise, Chevy unveiled its all-new Midget racing engine at Indianapolis Motor Speedway recently. It was a big official deal with GM representatives and United States Auto Club (USAC) team owner Tony Stewart there to see it off.

"One year ago, Chevrolet announced its sponsorship of Tony Stewart Racing (TSR) in open-wheel competition," says Chevrolet general manager Ed Peper. "Now, Chevrolet has taken the next step by creating an all-new racing engine for this popular grassroots racing series. Chevrolet races to win and America's brand is aiming for more victories in this uniquely American form of motorsports."

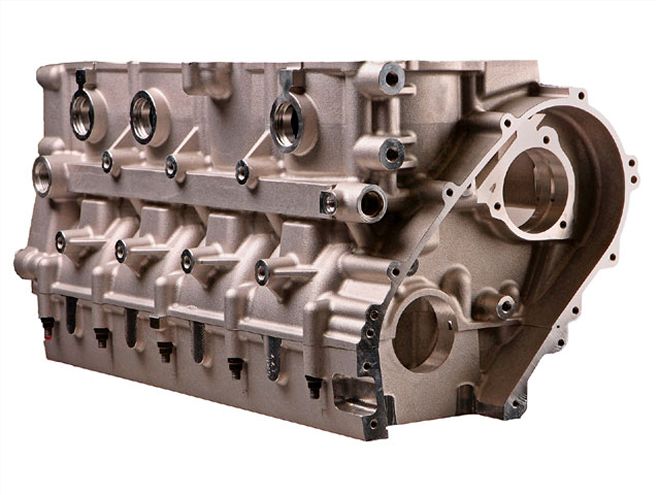

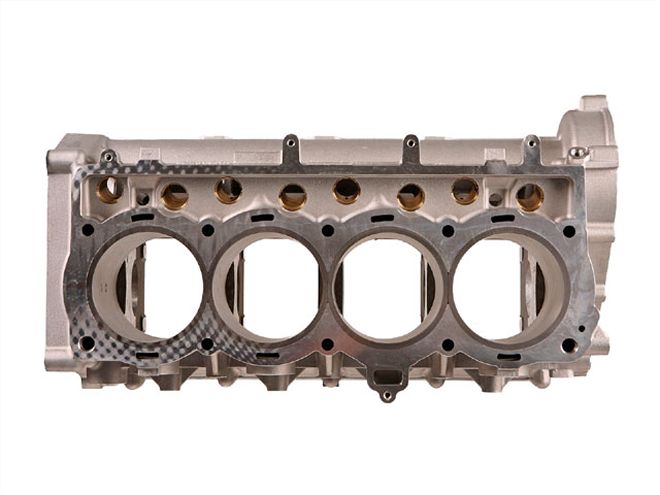

Here is a view of the block.

Here is a view of the block.

The new motor was designed by GM Racing specifically for the USAC Midget Series. The purpose-built, four-cylinder Chevrolet racing engine will initially power TSR drivers Tracy Hines and Levi Jones in upcoming events. The new engine will be available to all USAC competitors through independent engine builders. As this engine is brand new, the demand will initially outstrip supply until they become more available to the industry.

"The Chevy Midget racing engine is definitely going to be an asset to Tony Stewart Racing," says team owner Stewart. "Having the Chevrolet bowtie on the engine and not just on the side of the car as a sponsor is indicative of how much technical support the brand has given our program. In the past, we've competed with engines that were based on Chevy parts but weren't necessarily a Chevrolet engine. The Chevy Racing engineering and marketing staffs have really embraced the TSR racing programs, and the debut of this new engine is the start of another exciting new chapter in our relationship."

Let's start with the good stuff. The new methanol-burning 166ci (2.7-liter) Chevy Midget engine produces more than 350 hp. That's more than two horsepower per cubic inch. The lightweight, inline four-cylinder engine starts with an aluminum block and cylinder head. The head has two valves per cylinder operated by pushrods and rocker arms, is equipped with mechanical fuel injection and utilizes an electronic ignition system.

The block features dry-iron cylinder liners instead of traditional press-fit sleeves. Dry sleeve technology allows for quicker and easier repair should on of the sleeves suffer damage.

The block features dry-iron cylinder liners instead of traditional press-fit sleeves. Dry sleeve technology allows for quicker and easier repair should on of the sleeves suffer damage.

At the maximum displacement of 166 cubic inches and in compliance of USAC rules, the Chevy engine runs methanol fuel. The inline four aluminum block has dry iron cylinder liners; the kind that are simply put in place and usually retained by the application of the head. This is opposed to a press fit where the sleeves are 'frozen' and temporarily shrunk in a freezing liquid such as nitrogen or CO2 and then squeezed into the block. 'Dry' sleeve technology allows the block to act much like a tool holder for all the engine's components. Also, a damaged sleeve can easily be repaired-quite possibly at the track.

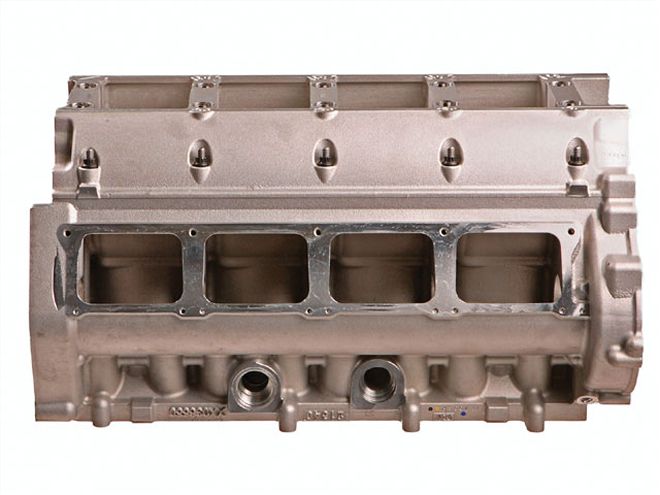

The engine uses a gear-driven mechanical roller camshaft and shares its 6.5-inch crankshaft-to-camshaft dimension and 60mm camshaft core diameter with the championship-winning Chevrolet R07 NASCAR engine. A bigger diameter cam will provide more finite cam designs, allowing for tuning to track applications.

The Midget motor's belt-driven dry sump oil pump and high-pressure mechanical fuel pump are mounted on the right side of the engine. With these components located outside the block, they are more accessible for maintenance. Also, being on the 'cold' side of the block (the exhaust comes out on the left side) they are less susceptible to heat damage.

All the specs of the new engine fall in line with USAC rules which apply to a wide swath of engines including four and six cylinders, two-valve and four-valve cylinder heads, overhead valve, single overhead cam, and dual overhead cam valvetrain designs. The new Chevy Midget racing engine uses the same proven pushrod/two-valve layout that has been the standard of GM small-block V-8s since 1955, retaining the now-classic design's core of simplicity, reliability and light weight.

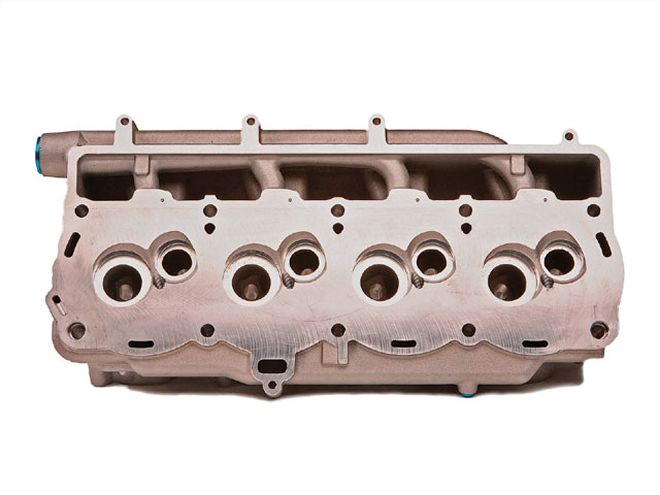

The engine uses an innovative architecture that improves its combustion efficiency featuring two valves/cylinder as seen here.

The engine uses an innovative architecture that improves its combustion efficiency featuring two valves/cylinder as seen here.

Yet, Chevy engines put a new twist on this familiar theme. While some series have adopted rules that tightly define virtually every component and dimension in a racing engine, the USAC Midget Series offers engine designers the freedom to innovate. The opportunity to think "outside the box" is the kind of challenge that appealed to GM Racing engineers. Their innovative design of the new Chevy Midget racing engine is the product of imaginative thinking and advanced technology. Just the kind of thing any successful racing operation needs. Throw in some of those already-proven racing ideas and you've got yourself the foundation of a good motor.

Starting with today's version of a blank piece of paper-an empty computer screen-GM Racing engineers developed a package that is a departure from the engines traditionally used in Midget racing. The new Chevy motor has an innovative architecture that improves its combustion efficiency, enhances airflow and lowers the center of gravity. Advanced technical resources such as computational fluid dynamics and solid 3-D modeling used to design GM production engines were also used to develop the Chevrolet Midget racing engine.

Here is the same head from the other side.

Here is the same head from the other side.

Computational fluid dynamics (CFD) are used to determine the flow of liquids and gases inside the block and heads while it is still in the design stage and on the computer. Recent advancements with this relatively new form of computer work allow flows to be maxed out for efficiency and volume right from the start. Water flows, for one example, are so effectively controlled that they are now routinely held to a five degree variance anywhere in the engine.

Solid 3-D modeling helps in getting the products to the finish stage. Instead of making the first cast prototype pieces with new, handmade molds, the newly designed parts are first made of layers of a type of paper. Many of the growing pains of a new casting are eliminated by making these paper versions first while still in the design studio instead of the casting plant. Once engineers are happy with the paper versions, they can sign off for the first metal pieces to be made. Likewise, the casting plants are now working on a much faster turn around time than they have in the past. What used to take six months to bring about a part is now often delivered in less than three.

The new Chevy Midget motor uses a belt-driven dry sump oil pump mounted on the right side of the engine, providing easy access for maintenance and protection from exhaust heat.

The new Chevy Midget motor uses a belt-driven dry sump oil pump mounted on the right side of the engine, providing easy access for maintenance and protection from exhaust heat.

"The Chevrolet Midget racing engine represents another step in GM's continuous development of high-performance, high-rpm overhead-valve engines," says Tom Stephens, executive vice president, GM Global Powertrain and Global Quality. "Like the championship-winning Chevrolet R07 in the NASCAR Sprint Cup Series and the record-setting LS.7R small-block V-8 in the American Le Mans Series, the new Chevrolet Midget engine was designed and developed using many of the tools and technologies GM engineers employ to create exceptional production engines like the new 638hp LS9 small-block V-8."

The major components that define the Chevrolet Midget engine package-the cylinder block, cylinder head and certain ancillaries-will be available to all USAC competitors. Independent engine builders, such as Kistler Racing Engines of Fremont, Ohio, who supply the Chevy engines that power the two TSR entries, can then assemble engines using remaining internal and external components from their preferred suppliers.

"Many of the aftermarket engines currently racing in the Midget series are based on the four-cylinder Chevy II engine produced in the '60s," explains GM Racing director Mark Kent. "Others are essentially one bank of a conventional V-8 engine. We took a different approach to bring innovative technology to the series while respecting a racing heritage that reaches back to the '30s. We've also incorporated lessons learned in designing and developing race-winning engines for NASCAR, ALMS, and NHRA competition. By harnessing GM's technical resources to create a brand-new Midget racing engine, we're putting more Chevy into the cars that wear bowties on the racetrack."

While you can create one of these engines by cutting a V-8 in half, the Chevrolet design team started with a blank slate so that they could relocate the cam and pushrods to the exhaust side of the cylinder case, which opened up new options in positioning the spark plugs and fuel injector nozzles.

While you can create one of these engines by cutting a V-8 in half, the Chevrolet design team started with a blank slate so that they could relocate the cam and pushrods to the exhaust side of the cylinder case, which opened up new options in positioning the spark plugs and fuel injector nozzles.

And that raises the question of, what's wrong with just cutting a V-8 in half? That's been done before successfully, right? Dennis Weglarz, manager, GM Racing Powertrain answers with, "Creating an overhead-valve Midget engine by cutting off one cylinder bank of a V-8 engine positions the camshaft on the intake side of the engine. Our key design decision was to relocate the cam and pushrods to the exhaust side of the cylinder case. This opened up the intake side of the cylinder head and allowed our engineers to optimize airflow without compromising the intake ports to accommodate the pushrods. Relocating the camshaft to the exhaust side also opened up new options in positioning the spark plugs and fuel injector nozzles. It also locates the camshaft lower in the chassis and offsets its weight to the left side of the car, which can be advantageous to handling. The exhaust-side camshaft is really the cornerstone of the Chevy Midget engine's design concept."

Speaking of weight, Chevy is being cagey about what the new motor actually weighs. When pushed for an answer, they say only it is within current, competitive engine weights. That would put it less than 250 pounds But with the new manufacturing design of the block and heads, it's easy to see there is no wasted metal. Traditionally, when factories give out stats such as weights and actual horsepower numbers, they are usually conservative at best. Still, the idea of over 350 hp in less than 250 pounds of four cylinders makes for a healthy motor.

Chevy is being cagey about the exact weight of the new motor. But take a look at the block from this angle, there is no excess metal here.

Chevy is being cagey about the exact weight of the new motor. But take a look at the block from this angle, there is no excess metal here.

GM also kept one eye on the type of racing where this engine would see duty. "Another key decision that enabled the innovative repackaging of the valvetrain was to invest in an all-new block and a cylinder head that wasn't constrained by the limitations of being usable in other forms of racing," says Pat Suhy, GM Racing group manager, Oval Track. "Our goal was to produce an engine with power that's equivalent to the most powerful engines currently competing in the USAC Midget series while maintaining a wide power band. Midget racecars run without transmissions, and they race on tracks that range from 0.1-mile arenas to the one-mile Phoenix oval. The engine's operating rpm range extends from 4,000 to 9,000 rpm, and throttle response is critical, especially on dirt tracks where the driver uses the throttle to help turn the racecar."

And then there are the costs involved. "Another important consideration for a grassroots racing series is cost," Suhy notes. "Our objective was to produce an engine that delivers great performance for the money. The Chevrolet brand has always stood for value, and the Chevy Midget racing engine will continue this tradition."

Levi Jones behind the wheel testing the new motor. The TSR driver had nothing but praise for the new engine.

Levi Jones behind the wheel testing the new motor. The TSR driver had nothing but praise for the new engine.

Initial track tests by Tony Stewart Racing have confirmed that GM Racing hit the mark with the new Chevy Midget racing engine. "So far in testing, we've learned that the Chevy engines don't ever seem to run out of power," says Tracy Hines, driver of the No. 21 TSR/Chevy/Spike USAC National Midget. "From the instant you get on the gas, the engine never quits pulling. They're strong on both the bottom and top ends of the power band, and it feels as though the engine has power in reserve. Chevy has built a great piece and I'm really looking forward to competing with these engines."

TSR plans to complete its transition to Chevrolet power as soon as possible. "The opportunity to be a part of the development and debut of the new Chevy Midget engine is something that I'm really proud to be involved with as a driver," says Levi Jones, driver of Stewart's No. 20 Midget. "Looking back at the history of open-wheel racing, there have been several influential engine programs that have left their mark on the sport. To be one of the drivers to compete with the first-ever Chevy branded USAC engines will definitely always be one of my career highlights."

Midget racing has had a long and storied career of ups and downs in popularity. As it seems to be surging once again, this new piece can help draw even more attention. We're watching to see if it attracts some of the other Detroit biggies to get involved.