'There's something about big-block Chevys that demands big cylinder heads. Maybe it's some sort of deep, genetic, missing-DNA-link thing between car crafters and Chevy Rat motors that insists on monstrous, rectangle-port cylinder heads. It's like some kind of baritone inner voice that won't be content with anything less than massive 360cc intake port heads on a 396.

We learned long ago not to listen to that caveman voice. Instead, we decided to look into how much power we could extract from a set of oval ports. That led us to stacking up all the available aluminum oval-port heads on a Rat and pushing 'em hard on the dyno. For a testbed, we used our existing cast-cranked 496 Rat motor built back in the Mar. '07 issue with plenty of displacement to really challenge these heads. We also included a set of production iron peanut-port heads just to see how they would do as a baseline. We really wanted a set of true iron oval ports, but we couldn't find any that hadn't already been ported. We also tamed the camshaft with a hydraulic roller so we wouldn't have to spin the engine as high to get the peak horsepower numbers. The results of this shootout were more than a little surprising. But be sure to read this entire story, not just glance at the power numbers, because we evaluated these heads in a bunch of interesting ways. Taken as a whole, the oval-port Rat market offers heads that are a lot stronger than you might think.

The Mule

If you recall, we built a 496ci Rat in the Mar. '07 issue that made a stout 707 hp on pump gas with a set of as-cast 305cc AFR rectangle-port heads and a big Comp mechanical roller cam. We had to twist that combination up to 6,600 rpm to achieve that power, which created more than a few Internet blog predictions of imminent engine failure focused on the cast crank and stock rods. Despite those doomsday prognostications, the engine is still very much alive even after this latest thrashing. But acknowledging those realities, we know it's just tempting fate to continue to spin this thing that fast.

To remain consistent with a conservative oval-port street concept, we decided to pull back on the cam timing to keep the peak horsepower below 6,000 rpm. This milder Comp Cams hydraulic roller cam timing is also a better fit with the entire oval-port package, including the Edelbrock RPM Air-Gap dual-plane intake manifold and 850-cfm Barry Grant carburetor. If peak horsepower had been the goal, we would have chosen any one of many single-plane intakes that would have easily kicked it up over 600 hp. Taken as a whole, this engine package turned out to be extremely successful considering that the engine idles at 950 rpm with 12 to 13 inches of manifold vacuum and offers tire-shredding torque. That idle quality is also more than enough to support power brakes and perhaps even an A/C compressor. We'd call that very streetable.

CAM SPECS Cam: Comp Cams XE274HR-12 Hydraulic Roller Advertised Duration Lift Lobe Duration @ 0.050 (inches) Separation Intake 274 224 0.555 112 Exhaust 282 232 0.565Edelbrock Heads

The Edelbrock Performer RPM oval ports are an interesting mix within the collection of aftermarket aluminum oval-port heads. They offer the largest intake-port volume of 290 cc with the smallest 2.19-inch intake valve. Among the specs we list for each head is the intake port cross-sectional area. We measured each of the five heads in the same basic place in the intake port to determine the smallest cross-sectional area. This dimension, in square inches, is intended to give you an idea of which head will generate the highest intake velocity based on size. A smaller intake-port cross-section will generate a higher intake-flow velocity while larger ports will experience slower velocities. Intake-port velocity (up to a point) has been shown to have a positive effect on cylinder filling, which results in better power. The Edelbrock's intake-flow numbers are decent, although not on a par with the other three aluminum heads, and still performed well despite having the largest intake-port cross-sectional area number.

Another important consideration is that these heads rely on a stock exhaust-port exit position, which helps with header fitment. As we'll see in the dyno testing, the Edelbrock heads performed well in the horsepower test even though they did not win when evaluated strictly on torque and horsepower. But add in price and suddenly these heads are players, since they are the least expensive of all the aluminum heads we tested. Check out our dollar-per-horsepower evaluation and see if you agree that the Edelbrock heads make excellent fiscal sense.

Edelbrock Performer RPM-O "Roval"

2.19/1.88 valves

110cc chamber

Intake port volume: 290 cc

Stock location exhaust port

Intake cross-section: 3.07 sq. in.

PN 60479

Dart Heads

These are the newest castings amid the oval-port contenders. Clearly Dart was after serious performance since it fitted these 275cc intake ports with 2.25-inch intake valves. Only the TFS heads with 2.30-inch intakes are larger. From a port cross-sectional area standpoint, the Darts are the largest of all the heads we tested, which might have contributed to their overall torque curve performance. One other aspect of these heads that does not show up on the flow numbers is Dart's emphasis on wet-flow development work.

Dart also raised the exhaust-port exit 0.300 inch, which is a major reason the high-lift exhaust-flow numbers are so strong. What's interesting is that both the Dart and TFS heads offer a 0.300-inch raised exhaust port and that both the Dart and TFS heads' exhaust-port flow numbers make a significant jump at the higher valve lift, virtually duplicating each other as seen on the exhaust-port flow charts.

Dart 275 Oval Port

2.25/1.88 valves

119cc chamber

Intake port volume: 275 cc

Raised exhaust port: 0.300 inch

Intake cross-section: 3.26 sq. in.

PN 19000112

TFS Heads

If you look at the flow curves, the TFS and Dart intake-flow numbers virtually overlap throughout the entire flow curve on both the intake and exhaust, which is surprising. Despite this, there are a couple of items that differentiate the TFS heads. First, the TFS intake port has the smallest cross-sectional area of all the aftermarket heads at 2.84 square inches, while the Dart has the largest by a wide margin. The second point is the raised exhaust port, which creates excellent exhaust flow numbers that would probably benefit from a single-pattern camshaft design.

TFS Oval Port

2.300/1.88 valves

113cc chamber

Intake-port volume: 280 cc

Exhaust port raised 0.300 inch

Intake cross-section: 2.84 sq. in.

PN 41300002

Valve Intake Exhaust E/I Lift (w/ pipe) 0.100 69 61 88% 0.200 141 126 89% 0.300 209 159 76% 0.400 260 192 75% 0.500 292 221 75% 0.600 318 246 77% 0.700 325 264 81%

E/I is the exhaust-to-intake flow relationship expressed as a percentage.

Brodix Heads

The Brodix Race-Rite oval-port heads are an interesting approach. When we first flow-tested these heads, we were impressed with their out-of-the-box performance. Then when the idea for a test came along, Brodix offered a set of CNC-machined chamber versions that we didn't have time to flow-test. According to Brodix's Web site, this chamber mod should be worth roughly 4-5 cfm across the entire valve-lift curve. This also adds another $225 to the price of the heads. This change also bumped the compression, which is why this modification is worthy of consideration. Generally, a CNC chamber is also worth some combustion efficiency that is hard to measure unless we did some kind of back-to-back test on the same set of heads.

The Brodix has a decent exhaust port, but because it is a stock exit-location port, the exhaust-flow numbers are not as strong as the TFS or Darts. This may explain why the Race-Rites benefited at the top a little more from the dual pattern cam. Our only complaint with these heads is that the valve-cover rail is low and spills oil on the headers when we remove the valve covers. Brodix chose to do this to make the heads easier to fit into tight engine compartments faced with clearance problems around A/C compressors and power brake boosters. Overall, this is a great oval-port cylinder head.

Brodix Race-Rite Oval Port

2.25/1.88 valves

Chamber 118 cc (110 cc CNC as tested)

Intake-port volume: 270 cc

Stock exhaust-port location

Intake-port cross-section: 3.08 sq. in.

PN 2061001 (RR BB-O)

Valve Intake Exhaust E/I Lift (w/ pipe) 0.100 74 64 86% 0.200 163 113 69% 0.300 218 145 66% 0.400 267 171 64% 0.500 306 194 63% 0.600 328 216 66% 0.700 341 234 68% 0.800 348 244 70%

Note: This flow data was collected on an as-cast head without CNC chamber mods.

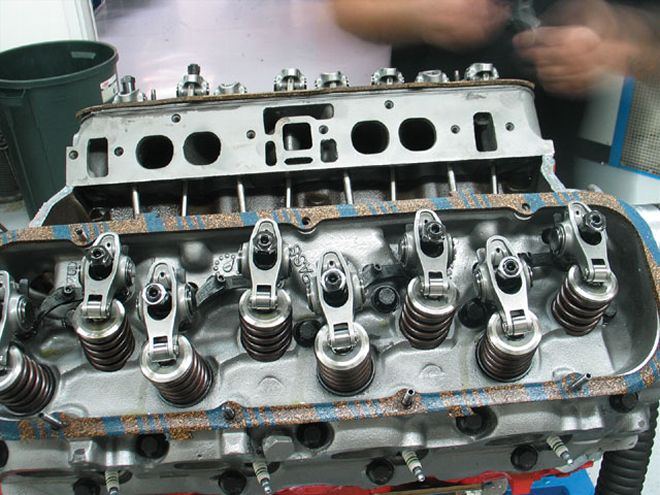

We set up the peanut-port heads with the same good Comp valvesprings, titanium retainers, and roller rocker arms. We also used a set of Comp 0.300-inch-thick spring seat inserts to take up the extra room created when we got rid of the stock exhaust-valve rotators.

GM Iron Peanut Port

This cast-iron head is called the peanut port because the intake ports are not much larger than their namesake. Omar Cabrillo at Coast Motor Supply in Canoga Park, California, helped us out by supplying a pair of the heads complete with tiny stock valves, new guides, and a basic valve job. These peanut ports are roughly 30 percent smaller than an aftermarket 270cc version. There are larger factory oval-port, cast-iron, open-chamber heads at 250 cc, but the only ones we could find had been modified, which would not be representative of an OE head. But don't count these peanut clusters out. If you were looking to build a budget-oriented Rat for towing where power above 4,500 rpm was not a concern, these heads would be an excellent choice with almost 600 lb-ft of torque at 3,200 rpm. If you were to pocket-port these heads and add larger 2.19/1.88-inch valves, you could make 530-plus horsepower. That's not bad for iron castings.

GM 236 Iron Peanut Oval Port

2.06/1.72-inch valves

120cc chamber

Intake-port volume: 208 cc

Stock exhaust port location

Intake-port cross-section: 2.43 sq.in.

The Setup

There are a boatload of variables involved in testing five different Rat motor heads. We quickly discovered that each of them demanded wildly different pushrod lengths based on changes in valve length. For example, both the TFS and Dart heads use 0.250-inch-longer intake valves that require a taller pushrod. Brodix adds 0.100 inch to both the intake and exhaust valves, while the Edelbrock valves are stock length. And don't forget, we skewed this whole deal with a hydraulic roller cam that uses a much taller lifter, which effectively shortens the pushrods. Mix in the fact that all Rat motors use different-length intake and exhaust pushrods and you've got a major science project just in pushrod lengths. After much gnashing of teeth, we ended up with six different pushrod lengths for our five subject heads. Just for fun, many of the heads also required lash caps on some of the valves to create sufficient clearance between the Comp steel Magnum 1.7:1 roller rockers and the valvespring retainers. Whew! The next time you hear a buddy complain about how much money custom engine builders ask for assembling an engine, smack them upside the head and tell them we put a solid 20 hours into setting up these heads so that they would perform (and survive) as intended.

But wait-there's more. We also realized that in order to generate a truly fair comparison, all the heads would require the same valvespring pressure. This would eliminate valve float as a variable, which was very important. One item we had no control over was that larger-diameter valves automatically weigh more than smaller valves. To accommodate all the different valve weights, we decided on a Comp Cams PN 933 spring with a common installed height of 1.950 inches. The 933 measured 175 pounds at 1.950-inch seat height with 440 pounds of open pressure at 0.550 inches of valve lift.

Finally, all but one of these heads required its own specific head bolt set as well. It took a big stack of ARP fasteners to get the job done, and we appreciate all the help that ARP gave us to make this test successful.

Pushrod Chart

Because these heads were fitted with several different valve lengths, this demanded multiple custom pushrod lengths. Comp's adjustable checking pushrods and broad Hi-Tech 31/48-inch pushrod selection made it easy to set up the proper rocker geometry with custom pushrod lengths in 0.050-inch steps. The following chart lists the pushrod lengths we established for our hydraulic roller-cammed 496, but you should still take the time to measure your own required lengths to ensure accuracy. The chart lists each Comp Hi-Tech pushrod length (in inches) with each part number in parentheses underneath. These Comp Hi-Tech pushrods can be ordered either individually or in sets of 16.

Lightweight Retainers

The problem with big-block Chevys has always been big, heavy valves and valvetrain parts. That's why all aftermarket big-block Chevy heads come with 111/432-inch valve stems instead of the stock 31/48-inch stem. Since valvetrain weight is an issue, we elected to use the Comp 933 dual springs matched with a Comp 10-degree titanium retainer to reduce weight. The difference in weight between the normal-steel 1.550-inch-diameter retainer at 35 grams and the titanium at 18 grams is almost half at 17 grams. This may not sound like much, but it's huge. Just as we completed our testing, we learned about new lightweight tool steel retainers from Comp Cams that are only slightly heavier than titanium, yet as strong as steel and, best of all, roughly half the price! We've included the part number in our parts list. By reducing valvetrain weight, we don't have to run as much valvespring pressure, which makes life easier for the entire valvetrain. How often do you get an improvement in performance while also reducing cost? Technology is a wonderful thing.

Compression Lessons

Each of the heads we tested had a slightly different combustion-chamber volume, which means static compression was another unfortunate variable in this test. The accompanying chart indicates the variation in compression. Both the Edelbrock and the Brodix (with its CNC machining) had the smallest chambers, so they benefited from the highest compression, while the Dart had the largest chamber and therefore the least compression. The difference is almost a full point of compression, and since one point is worth roughly 2 to 3 percent power, both the Edelbrock and Brodix probably received a decent horsepower bump. Had we milled the Dart heads to 110 cc, for example, that might have added another 10 hp, which would have made a significant difference throughout the entire power curve, perhaps pushing peak horsepower very close to 600. Yahoo!

We bolted in a set of coated Hedman 2-inch street headers in our '66 Chevelle chassis to see if the raised exhaust-port heads like the Dart and TFS would fit, which they did very nicely, thank you.

Test Fit

One of the biggest headaches for big-block engines is packaging the exhaust. When we began this test, it appeared that the raised exhaust ports on the Dart and TFS heads might be a problem when it came to fitting chassis headers in a car, so we decided to put the heads to a simple test. We bolted a 454 iron-block in a '66 Chevelle along with the stock steering column and Energy Suspension motor mounts. We then bolted on the Edelbrock heads along with a set of Hedman 2-inch chassis headers. The Edelbrock heads fit with no clearance problems, so we then tried a TFS head with the same headers. One tube came very close to the steering column and probably would require a slight dimpling, but that was the only real consideration. We did not have the clutch linkage in place, but that did not appear to be an obstruction. Overall, we were pleasantly surprised that the raised exhaust-port heads still allow the headers to clear, which means we wouldn't have to do header surgery in order to make them fit.

Test Variables

As you've seen, three of the four heads in our test are very close in overall power. One variable that affects any test like this is cam timing. In this case, we chose a dual-pattern camshaft that offers 8 degrees more exhaust duration compared to the intake side. This probably helped the Brodix and Edelbrock heads that had less favorable exhaust flow numbers while perhaps hurting the Dart and TFS heads slightly. The Dart and TFS heads both have raised exhaust ports and strong exhaust flow numbers that likely would have responded with more power by using a single-pattern camshaft. We really can't say that with certainty unless we test this idea, but we have seen results like that with other engines offering high-flow exhaust ports. This is the problem with choosing one camshaft profile for testing multiple cylinder heads. It's entirely possible that the Dart and TFS heads would have produced much stronger peak torque and horsepower numbers had we chosen a single-pattern camshaft. Now you can see why the results of this kind of testing cannot be considered chiseled in stone unless a whole battery of cams go with it. This just gives you something more to think about.

This is the PN without the CNC chamber Brodix option CNC-chamber price $225.00

The Test

Once we had all the heads assembled and configured, we loaded up the Rat and all the heads and assorted accouterments in the back of our trusty GMC pickup and piled it all up in the dyno cell at Westech. Steve Brul put on his kidney belt, and we set to work thrashing on the Rat.

The procedure for the first test was to bring the engine up to temperature and then go through a series of jetting and timing tests to establish the baseline for the rest of the cylinder heads. It turned out that all the heads used 36 degrees of lead and the same jetting from the Barry Grant Mighty Demon carburetor, which made the thrash a little easier. Once we had a good tune-up, we made three full pulls on each combination from 3,200 to 6,200 rpm, then averaged those runs together to create a power curve for each engine.

Looking at the numbers, the iron heads performed better than we thought they would, while the aluminum heads were very close in terms of overall power. If you look at the overall torque curve of the four aluminum heads, all four are extremely close from 3,200 through roughly 4,800 rpm, where the Edelbrock heads begin to drop off slightly. That also shows up on the horsepower curve. While the power difference appears significant on the horsepower charts, please read the Simulated Dragstrip sidebar. We tested all five heads in a digital Chevelle down a virtual quarter-mile. What you'll discover is that this power discrepancy is not nearly as critical as it appears.

What's also interesting is that the intake flow curves on the TFS and Dart heads are almost identical, which transfers over to the horsepower and torque curves. Rather than get bogged down by too much detail about the power curves, it may be more important to point out how amazingly close all four heads were in terms of average power. With an average torque difference of only 8.7 lb-ft and an average horsepower difference of even less at 8.1 hp, there's a average spread difference of 1.5 percent. That's almost imperceptible in the car.

What all this means is that you really can't make a bad choice when it comes to any of these heads. Especially when you consider that there was a slight difference in compression. Had we evened up the static compression, it would certainly have helped the Dart and TFS heads the most, especially in terms of peak numbers, but it also means that the average differential would probably be a little wider, but still around 2 percent.

Also, since the cam was intentionally conservative, it's clear from the flow-bench data that all of these heads would respond with more power with another 0.030 to 0.050 inch of additional valve lift. That could come in the way of a switch to perhaps 1.8:1 roller rockers, because it gives us the lift without having to go to a longer duration that will only kill some of that brutal low-speed torque.

What's truly impressive is that this simple, oval-port, hydraulic roller-cammed 496 is capable of cranking out almost 630 lb-ft of torque at a very streetable 4,000 rpm with oval-port heads and a dual-plane intake manifold. We plan to bolt a single-plane intake on the Dart head package, and this will certainly push our 496 into the 600-plus horsepower zone. Either way, this is a killer power package disguised in conservative attire. So build a 496, paint the heads and dual-plane intake manifold orange, tell the world it's a mild 396, and blow their doors off. You just might get away with it-until the word gets out.

POWER CHART Iron Stock Edelbrock Dart TFS Brodix RPM TQ HP TQ HP TQ HP TQ HP TQ HP 3,{{{200}}} 595 363 610 372 605 368 612 373 619 377 3,{{{300}}} 594 373 609 383 604 379 612 384 614 386 3,400 594 385 611 396 606 392 614 398 615 398 3,500 595 396 613 408 608 {{{405}}} 617 411 618 412 3,{{{600}}} 595 407 613 420 610 418 619 424 621 426 3,700 593 418 615 433 612 431 622 438 623 439 3,800 592 428 616 457 614 444 624 452 624 452 3,{{{900}}} 591 439 618 459 615 457 {{{626}}} 465 625 464 4,000 590 449 618 471 615 468 626 477 626 477 4,{{{100}}} 589 460 617 482 614 479 625 488 626 488 4,200 587 470 615 492 611 489 622 498 623 498 4,300 585 479 612 501 609 498 619 507 620 507 4,400 581 487 609 510 606 508 616 516 616 516 4,500 577 495 607 520 604 518 614 526 613 525 4,600 572 501 605 530 603 528 613 537 611 535 4,700 565 506 602 539 602 539 610 546 609 545 4,800 558 510 598 547 600 548 607 555 606 554 4,900 551 514 593 553 597 557 604 563 602 561 5,000 543 516 587 559 593 564 599 571 598 569 5,100 534 518 582 565 588 571 595 578 593 576 5,{{{200}}} 525 519 576 570 583 577 590 584 588 582 5,{{{300}}} 515 520 570 575 578 583 583 589 583 588 5,400 507 521 563 579 572 588 576 593 576 593 5,500 496 519 555 581 566 593 568 595 569 596 5,{{{600}}} 487 519 546 582 558 595 558 595 560 597 5,700 476 517 536 582 549 595 547 594 550 596 5,800 465 513 527 582 538 595 537 593 538 595 5,{{{900}}} 451 507 518 582 528 594 527 592 528 593 6,000 438 500 510 582 519 593 517 590 517 591 6,{{{100}}} 423 492 500 581 506 588 {{{505}}} 586 507 589 6,200 407 481 487 575 494 583 490 579 495 584 Peaks and Averages Avg. TQ Avg. HP Peak TQ Peak HP Iron 541.1 475.0 595 521 Edelbrock 582.1 514.9 618 582 Dart 584.2 517.7 615 595 TFS 590.3 522.5 {{{626}}} 595 Brodix 590.8 523.0 626 597Price Vs. Performance

Here's where this gets interesting. The Brodix, Dart, and TFS heads all made strong peak power, leaving the Edelbrock slightly behind. Then we divided the price of each pair of heads by their peak horsepower. Here, the Edelbrock is the clear winner in terms of horsepower per dollar. One note for clarity's sake: We added the price of the Brodix CNC chamber modification to the price of the heads, since that's the way the heads were tested. What this shows is that the Edelbrock heads offer excellent power for the money. There's something to be said for combining value with all-out power.

Simulated DragStrip

Here's where we make dyno numbers relevant to the street. Testing each of these heads in the same car would have been fun, but there wasn't time, and they closed our favorite dragstrip. So we did the next best thing and loaded each of the five Rat head power curves into a simulated 3,700-pound street car with a TH400 trans, 3,000-rpm-stall speed converter, a 3.55:1 gear, and 28-inch-tall sticky tires 12 inches wide. Using the Quarter Pro dragstrip simulation program, we ensured that tire spin was eliminated so that we could evaluate each head based on its true potential.

We simulated a typical 80-degree day just above sea level, so these numbers are relatively quick. Even if a normal street car could hook up (which is questionable), these e.t.'s and speeds are probably a bit optimistic. Nevertheless, the differential between all the aluminum Rat heads is small-merely 0.08 second and 1 mph. Now factor the price again into this equation and you can see that the Edelbrock heads look really good. The Brodix, Dart, and TFS are so close that reaction time would determine the winner in that race. Also note that even those lame peanut-port heads pushed the test car into the very low 11s. This is bench racing at its finest.

Cylinder Head Quarter-Mile Simulation Iron peanut port 11.05 @t 120.0 Edelbrock 10.69 @ 124.8 Dart 10.63 @ 125.6 TFS 10.{{{62}}} @ 125.8 Brodix 10.61 @ 125.8