'Face it: Bigger is better. Since it's a jungle out there, where the meek get eaten for lunch, if you wanna be Tarzan, you'd better swing a bigger club. The days of a 396 or even a 454 as king of the jungle are long gone. When we stumbled upon this used 496ci Rat motor for a righteous price, we snapped it up thinking we could build an affordable big-inch Rat. The problem comes from using the terms "affordable" and "Rat motor" in the same sentence. Nevertheless, that's the challenge we decided to take on. We think Tarzan would approve.

We knew that bitchin' cylinder heads, a good cam, and a healthy carb and intake would be where we would have to spend our money, and that's exactly what we did. There are dozens (if not hundreds) of ways to build a strong, normally aspirated big-block Chevy, so this opened up a ton of options. And since we made over 700 hp on the first try, this is not the last time you will see this motor.

The Beginning

It was a typical Sunday at the swap meet. There, among the cheap rags and rusty Buick valve covers, was a lump of black-painted iron. It didn't look like much, really. Taped to its side was a hand-scrawled sign that proclaimed this particular round mound of poundage as a 496ci Rat motor (4.310 bore, 4.250 stroke). The owner couldn't remember who made the crank ("Scat . . . maybe," he said), and he wasn't sure if it was even a four-bolt main block. Despite his vague description, he looked honest. Even its history was dubious: "When we pulled it, it wasn't running right." But the price was right at $800, so we took a chance and loaded the lump in the back of our GMC pickup.

A quick autopsy revealed the deck was anything but square, but at least the cam wasn't flat. We found a 1-inch length of broken pushrod lodged in the oil-pump pickup, and most of the bearings were hideously scored. It looked like our Rat had been assembled on the floor of a rodeo ring with all that bulls%*# and dirt in the motor.

We took our orphan Rat to the wizard machinists at Jim Grubbs Motorsports, where we discovered the four-bolt main block needed deck work and an align-hone to correct the oversized main-bearing-housing issues. JGM also resized the stock connecting rods that had previously been fitted with ARP rod bolts. At least the 0.060-over Speed-Pro hypereutectic pistons were in good shape. But we also discovered the valve pockets would have to be machined to clear the 2.250-inch valves used in the AFR heads we planned to run. A good portion of our budget was invested in JGM's quality machine work, but that also meant we now had control over all the clearances in the short-block, creating a solid foundation from which to build some power

Games Pushrods Play

The engine assembly went fairly routinely until it came time to set up the valvetrain. First, we had to adapt a 0.125-inch-thick aluminum plate to the inside of our stock timing-chain cover to get the proper 0.005-0.008 inch of camshaft endplay using a Comp Cams cam button. Then we ran into a snag with the pushrods.

The stock-length pushrods we thought would work fell far short, and we were puzzling until we did what some car crafters don't do-we read the directions. That's when we discovered these AFR heads come with 0.250-inch-longer intake valves and 0.100-inch-longer exhaust valves. This dictated custom-length pushrods to make the rocker-arm geometry work with the longer valves.

We used a pair of Comp Cams adjustable pushrods to determine the proper lengths. We started by adding 0.250 inch to the stock length of the intake pushrod and 0.100 inch to the length of the exhaust pushrod. Remember that Rat motors use different lengths for the intake and exhaust pushrods.

The technique is very simple: Establish a pushrod length that will place the roller tip of the rocker arm on the inboard third of the valve tip. This can be done by marking the top of a valve with a felt-tip pen and turning the engine so the lifter for that valve is on the base circle of the lobe. Install the rocker arm over the adjustable pushrod and wiggle the rocker to make a witness mark on the valve tip. Adjust the pushrod length until the witness mark is on the inboard third of the valve tip. This allows the rocker tip room to travel across the top of the valve tip without running off the edge. A too-long pushrod will place the pushrod too far outboard at the beginning of its travel. A too-short pushrod runs the risk of running off the inboard edge of the valve tip. We ended up with intake pushrods that were 8.500 inches long and exhaust pushrods that were a long 9.400.

Next, we discovered the proper intake pushrod length placed the inside radius of the rocker arm very close to the retainer. If we lengthened the pushrod, it only made the placement of the rocker tip on the valve-stem tip less desirable by moving it outboard, which we didn't want. The solution came from Westech's Steve Brul, who suggested running valve-lash caps on the intakes. This increased our clearance between the rocker arm and the retainer and also increased the contact area between the rocker-arm roller tip and the valve stem.

On The Dyno

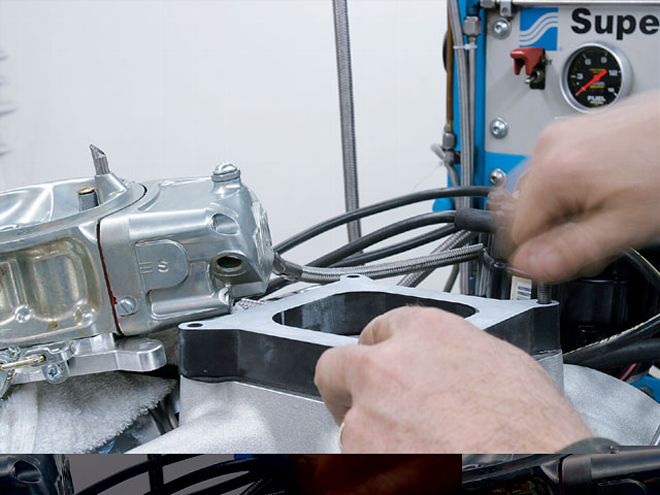

After we had carefully assembled the Rat and double-checked all our clearances, we loaded up the rotund rodent and bolted it up to Westech's SuperFlow dyno. To finalize the combination, dyno guru Steve Brul suggested a set of 211/44-inch Hedman dyno headers that connected to a pair of massive 4-inch exhaust pipes and a pair of Hedman 4-inch mufflers. To tell the whole story, Westech uses an electric water pump just to make testing simpler. But this means there are a couple of free horsepower here by not driving a mechanical water pump.

As for ignition, our budget was so bent, stapled, and mutilated there was only enough money left for a basic, used HEI and PerTronix 8mm budget plug wires, so that's what we went with, along with a set of cold-heat-range Bosch plugs to light the fire. As you can see from the test, this was more than enough to get the job done.

Brul always makes the very first pull on the engine after the oil and water temps are up to normal, and then it's a quick yank at a mid-rpm point to see if the timing at 36 degrees and the stock jetting are where they should be. The first pull showed us 599 hp at 5,500 rpm. That's when we knew this was going to be a good day.

By experimenting with timing finalized at 34 degrees and jetting with two sizes out of the primary and secondary, our fat Rat leaned out to the tune of 685 hp. After a short skull session, we decided on a tighter lash on the intake lobes to increase the effective duration. This kicked the power up to the curve you see in Test 1 at 701 hp at 6,400 and 603 lb-ft of torque at 5,400.

Brul then suggested a simple little plastic 1-inch spacer under the carburetor because we were seeing as much as 2 inches of manifold vacuum at peak power, which indicated (as we expected) that the carb was a little too small for this power level. The spacer took the power to an amazing 707 hp at 6,400 rpm. Finally, we even tried a 14-inch-diameter K&N air cleaner that pushed the peak horsepower up to 708. We liked the 707 number so well, we decided to stick with that. Not bad for a cast-crank, pump-gas 496

Dyno Flog

Test 1 was run with two steps leaner jets than stock in the Demon 850 carburetor with timing set at 34 degrees total. We also tightened the lash on the intake valves from 0.016 inch to 0.012 inch to increase the intake duration.

Test 2 used all the conditions of Test 1 along with a simple 1-inch-tall, plastic, open-plenum spacer under the carburetor to improve the top-end power. In a final test (not shown here), we added a 14-inch, K&N, 3-inch-tall, air-cleaner assembly and peak power climbed to 708 hp. Also note the brake-specific fuel consumption (BSFC) numbers that dip into the 0.390s below peak torque. These are excellent numbers indicating very efficient use of the fuel. BSFC is expressed as pounds of fuel used per horsepower-hour (lb/hp-hr). Generally, any number under 0.500 is considered good; sub-0.400 is excellent.

RPM TEST 1 TEST 2 TQ HP TQ HP BSFC 3,000 514 294 518 296 0.463 3,{{{200}}} 528 322 527 321 0.442 3,400 544 352 549 355 0.422 3,{{{600}}} 547 375 552 378 0.414 3,800 545 395 550 398 0.412 4,000 552 421 554 422 0.407 4,200 564 451 562 450 0.395 4,400 576 482 574 481 0.387 4,600 586 513 585 512 0.389 4,800 590 539 591 540 0.393 5,000 593 565 596 567 0.403 5,200 600 594 603 597 0.409 5,400 603 621 603 620 0.419 5,600 601 640 602 642 0.422 5,800 598 660 601 664 0.415 6,000 595 680 599 684 0.418 6,200 588 695 593 700 0.432 6,400 575 701 580 707 0.449 6,600 557 700 561 705 0.446 Avg. 572 527 575 529 0.417 Power/ci 1.21 1.41 1.21 1.42 We also tried a simple, polymer, open-plenum carb spacer that ended up being worth 6 hp at the peak. This worked to improve the plenum volume and also created more room between the bottom of the carburetor and the floor of the manifold to allow the air and fuel to turn the corner into the ports.

CAM SPECS CAM DURATION

We also tried a simple, polymer, open-plenum carb spacer that ended up being worth 6 hp at the peak. This worked to improve the plenum volume and also created more room between the bottom of the carburetor and the floor of the manifold to allow the air and fuel to turn the corner into the ports.

CAM SPECS CAM DURATIONAirFlow

Before we assembled the engine, we flow-tested the as-cast AFR 305cc heads on JGM's SuperFlow 600 flow bench at 28 inches of test depression using a 4.280-inch bore diameter. We also used a handformed clay radius for the intake entry, and no flow tube was used on the exhaust. We also tested both the "good" and "bad" intake ports to give you both flow curves. The good intake ports aimed the intake flow toward the center of the cylinder while the bad intake ports aim the intake flow toward the cylinder wall. This is the main reason for the differences in flow.

We tested the AFR 305 heads on a slightly smaller bore size (4.280 inches) compared with our 4.310-inch-bore-diameter 496 Rat. Many published big-block flow tests use the much larger 4.500-inch bore size. This simple 0.220-inch bore-diameter increase is worth a few cfm in both intake and exhaust flow. So when comparing Rat head-flow numbers, pay close attention to the flow bench's test bore diameter. For example, AFR publishes a 367-cfm flow number at 0.600-inch lift when measured on a 4.600-inch bore, while our number, measured on a 4.280-inch bore, is 347 cfm. Keep in mind that max cam lift is calculated without the lash. This means our actual intake valve lift was really closer to 0.645 inch (0.660 - 0.012 = 0.648 inch), including assuming a few thousandths for valvetrain deflection.

By the numbers

AFR 305cc, as-cast, rectangle-port heads2.25/1.88-inch valvesCNC-machined combustion chamberCFM

More Power

Here's what our dyno test reinforced from what we already knew about our 496-inch Rat. The big deal is clearly the induction system. We've seen plenty of 500-plus cubic inch Rats run to know that a 1,050-cfm carb would be beneficial. Our budget also forced us to use a stock pan-so there's a few horsepower in a good oil pan and tray assembly. It would also be nice to run thinner piston rings and forged pistons and maybe a point more compression. With all these ideas, it's possible with the parts and more tuning we could make 730 hp. If you think that's worthwhile, let us know and we'll put the whip to our phat Rat.