It's no secret that unlocking the power potential of an engine requires unlocking the airflow through the cylinder heads. A set of stock Mopar big-block heads can move somewhere in the neighborhood of 220 cfm of air and produces a nice torquey engine. Common aftermarket replacement-style heads can push flow upward into the high 200s, which can provide sweet street/strip horsepower. Now, let's forget about nice and sweet, and just get plain mean. When Mopar Performance decided to put the gloves on and step into the ring with a killer cylinder head, they also decided not to pull any punches. To handle the development effort, Mopar Performance teamed up with Chapman Racing Heads. Real world-class ability in port-form development is a very specialized expertise, and there are only a handful of companies with the credentials of Chapman. At the professional racing level, Chapman has earned the kind of respect that can only be gained by putting teams in the winner's circle. They've done just that in highly-competitive venues, such as NASCAR, sprint cars, and pro drag racing. These guys back-up the big boys with high-end cylinder head development and flow research.

Take the Stage VI casting design, send it over to Chapman Racing Heads for some casting revisions, let them handle the precision machining, have 'em the cut the ports on their CNC, and what have you got? Big-block Mopar heads that cook the books on power output.

Take the Stage VI casting design, send it over to Chapman Racing Heads for some casting revisions, let them handle the precision machining, have 'em the cut the ports on their CNC, and what have you got? Big-block Mopar heads that cook the books on power output.

The Stage Vi

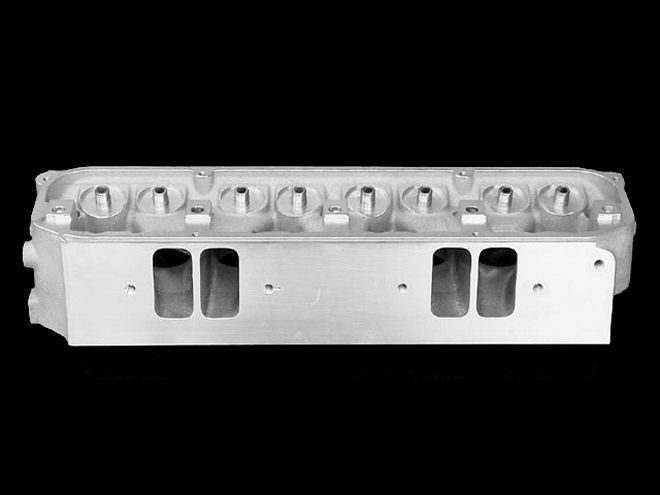

Mopar's Stage VI castings have been around for years, and this was the basic casting Chrysler brought to Chapman for development. The Stage VI was readily compatible with the existing big-block Mopar engine configuration and had some innovative and sound engineering behind it. The most unique aspect of the Stage VI is a raised intake runner, which essentially moves the intake port to the RB height on a low-deck block, allowing the engine's top-end combination to bolt together using a standard RB-width intake manifold on a low-deck block. In tall-deck applications, the wider spread between the raised intake ports is accommodated by either a set of Mopar Performance adapter plates (PN P5249189) or by using a dedicated Stage VI manifold. Ok, the runners are raised, and the engineers at Chrysler figured out a way to make it all bolt together. but why all the fuss? Raising the intake runner reduces the transition, or turn-in, to the cylinder and provides better flow potential. All else being equal, it's an edge in getting the airflow increased, but that isn't the whole story.

Chapman looked at what Chrysler brought to the table in the basic machined casting and saw, that while it had excellent potential, there was room for improvement. First, the Stage VI stubbornly retained Chrysler's original valve length of 4.86-inches. Again, so what? It's stock, right? The stock-length valve leaves a limited space between the top of the valvespring retainer and the seat in the combustion chamber, and there's quite a bit of stuff that needs to fit within that length. Think about it, that 4.86 inches has to accommodate about 2 inches needed for the spring, space for the valve tip, retainer, spring seat, and the roof of the casting. As with raising the runner, a taller short turn in the port floor offers better flow potential. The floor and short turn will need a good 1 inch or more of height from the valve seat to the port floor to get good flow. Now we've used up a big chunk of the space under the valve, and we haven't even considered room for the port. With the stock valve, space is at a premium, and the port height under the valve is crunched down to about 1.6 inches. That isn't much.

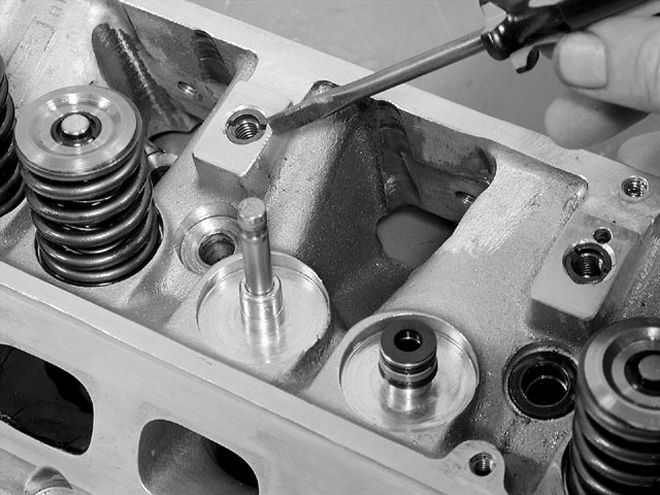

Because of the valve's inclination angle in relation to the deck, longer valves require a changed centerline for the rocker shaft. The shaft mounting location is milled flat, to work with a shaft mounting-blocks kit, Mopar Performance PN P5007742.

Because of the valve's inclination angle in relation to the deck, longer valves require a changed centerline for the rocker shaft. The shaft mounting location is milled flat, to work with a shaft mounting-blocks kit, Mopar Performance PN P5007742.

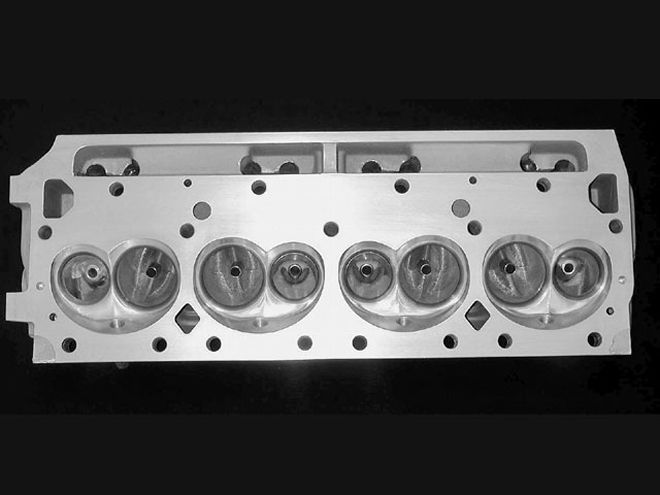

Interestingly, the Stage VI port is cast with plenty of material in the spring seat area, but it is also deeply plunge-cut during machining to make room for a spring with the short stock-length valves. The machining limits the port height in this critical area. A primary revision in the Chapman version was to upgrade to a longer 5.400-inch valve, adding .540 inch to this critical dimension. This frees some precious space for the port. To make use of the longer valve, the spring seat machining was altered, while still allowing room for a 2.00-inch installed height. Since the valves are inclined at 15 degrees, a longer valve moves the centerline of the valve tips inward towards the lifter valley. To accommodate this change, the rocker location is revised to match. Besides making the valve longer, Chapman saw no need to retain the stock 3/8-inch valve stem, preferring to reduce the stem size to 1 1/32 inch, which offered a considerable reduction in valve weight-a critical element in rpm potential.

The valve stem diameter is reduced from the production 3/8-inch to 1 1/32-inch, a move which reduces valve weight. Guides are phosphorous bronze. The longer valves allow ample space for a 2.00-inch valvespring installed height with spring locators installed. At this spec, there's a wide range of off-the-shelf, high performance springs available.

The valve stem diameter is reduced from the production 3/8-inch to 1 1/32-inch, a move which reduces valve weight. Guides are phosphorous bronze. The longer valves allow ample space for a 2.00-inch valvespring installed height with spring locators installed. At this spec, there's a wide range of off-the-shelf, high performance springs available.

The changes made to the valve specifications and machining represent the most obvious alterations to the familiar Stage VI, providing more flexibility in the port design. Port development is the hallmark of Chapman's operation, and an intensive effort was undertaken to produce a highly effective port shape to be replicated in the production versions with full CNC porting. Two versions of the Chapman CNC heads were developed, one with an intake port featuring a production-sized opening, and a large-port version with the Max Wedge style port window. Both of these heads would share a common exhaust-port design and 1.81-inch exhaust valves, while on the intake end, the large port version would receive 2.25-inch diameter valves, with the smaller head having 2.200-inch valves. With its larger intake ports, the Max Wedge sized head is much wider at the area adjacent to the pushrods, necessitating the use of .850-inch offset intake rockers for clearance. In tandem with the port development effort, the casting walls and water jackets were subtly revised to provide additional material as required to accommodate the final port configuration.

As might be expected of Chapman, the resulting flow is staggering, particularly considering the port sizes involved. The Chapman intake ports are remarkably efficient, drawing over 350 cfm through the standard intake port window of the smaller sized head (See Flow; Chart 2). This is a head compatible with commonly available, conventionally sized intake manifolds, and utilizing the stock valvetrain layout. Achieving that kind of flow level with a moderate 260cc runner, points out that the port efficiency is exceptional, and an efficient port is one that strikes the most advantageous balance of flow and velocity. The Max Wedge window head is equally impressive, raising the bar on intake flow to over 380 cfm, while adding a modest 25cc in volume. Again, the flow versus port size shows this to be an exceptionally efficient port configuration. Both cylinder head versions share the same exhaust port shape, with peak flow topping 250 cfm, without the aid of a flow pipe at the port exit. We had the opportunity to test the larger version of the Chapman heads on Westech's SuperFlow 600 bench, and found the advertised numbers to be valid, something that is not always the case with manufacture's numbers. On the exhaust side, the addition of a flow tube brought peak flow to just over 300 cfm.

We sealed the copper gaskets with a thin film of silicone around the deck openings at both sides. The pistons were fly-cut at the intake notches to provide the radial clearance for the 2.250-inch intake valves.

We sealed the copper gaskets with a thin film of silicone around the deck openings at both sides. The pistons were fly-cut at the intake notches to provide the radial clearance for the 2.250-inch intake valves.

QC For Me

One look around Chapman's facility, complete with the latest CNC machining centers, and you get the idea that these guys are serious about quality. The place has more an aura of a research lab than a machining operation. Early on, the MP Stage VI heads had developed a questionable reputation due to outsourced casting and machining. At the casting level, problems with porosity and core shift were reported. At the machining level, tolerance control sometimes required reworking of critical clearances by the end user. Chapman realized that casting consistency is an absolute requirement in having a sound foundation for a quality cylinder head. To accommodate the CNC port forms developed, revisions in the casting cores were required in order to put enough meat where it was needed, and a high degree of accuracy was demanded of the castings themselves. Along with revisions to the tooling, the casting operation was moved and contracted to Zeus foundry. This is the company that pours the metal for Chapman's NASCAR and Sprintcar P-7 and W-9 heads. We had an opportunity to view cutaways of final machined heads at Chapman's shop, and the casting quality was beautiful. The critical machining is handled in-house at Chapman's, and their reputation speaks for itself.

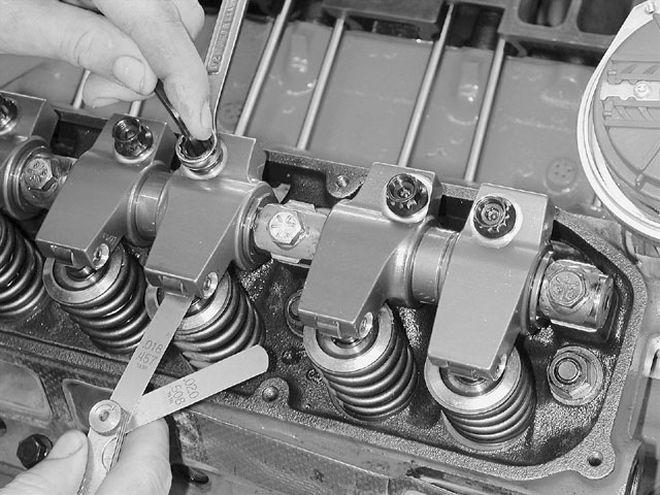

To keep things as equal as possible, the same rockers would be used on both sets of heads. The large-port Chapman heads required .850-inch offset rockers, so we used these 1.7:1 ratio offset Harland Sharpe rockers on the iron heads, even though standard rockers would be fine.

To keep things as equal as possible, the same rockers would be used on both sets of heads. The large-port Chapman heads required .850-inch offset rockers, so we used these 1.7:1 ratio offset Harland Sharpe rockers on the iron heads, even though standard rockers would be fine.

Power Please

Flow numbers, port volumes, dimensions, and the like, make us feel like scientists, but when all is said and done we're not specifications believers-we're horsepower junkies. The bottom line is just how much power is up for grabs with a smokin' set of heads? We thought that was a fair question, and set out to do a little experiment to find out. We obtained a set of the large-port MP/Chapman heads for our little exercise, and had on hand a healthy 470-cube low deck stroker short-block. The bottom end featured flattop pistons to deliver 12.6:1 compression, with a trick Total Seal ring set, and a custom Comp MM-series flat tappet solid camshaft with 260 degrees duration at .050. The bottom-end was custom-built for minimal rotating friction, and featured extensive internal oil control mods, mostly with hand-made parts.

As a basis of comparison, we had an extraordinary set of ported production 915 iron heads to run against. These iron wonders had been fitted with 2.25 and 1.81 valves, with extensively modified closed chambers. The ports were developed after an intensive R&D program, cumulating with over 45 man-hours of porting. Intake port flow topped 300 cfm with exceptional low and mid-lift flow-seldom seen territory for production based heads. For the traditional iron-head Mopar racer, we'll go out on a limb and say these heads are as good as it can get with the old-school ported and modified stock stuff-and we are willing to back it up.

We had the Westech crew bolt our 470 to the SuperFlow pump and arrived with the pair of top-ends for the challenge. First up were our 915's. These production-based heads retained the stock port window, so by necessity, the intake manifold would have to match. Linking the heads to the fuel mixer, we utilized Mopar Performance's low-deck M-1 intake, topped and blended to a Dominator adapter, to get intimate with a King Demon RS carb bearing a set of blue 1,250- cfm venturi sleeves. The combo worked really well. after a few jetting pulls, we found a set of 92 jets, coupled with 20 high-speed air bleeds, had the mixture at its optimal ratio. Output was a muscular 642 hp at 6,100 rpm, with a wrenching 611 lb-ft of torque, twisting the water wheel at 4,200 rpm. This combination was no pushover.

Next up, we had the 285cc Chapman Stage VIs. We set the bar pretty high with our baseline head, a combination we already knew worked. The large-port Chapman heads required a Max Wedge intake. We utilized a Max Wedge sized low-deck unit from Indy, which we matched to the heads with adapter plates. An RB intake would have been a direct bolt-on, however, we didn't have a MW-port RB intake on hand for the test. As with the iron heads, the intake was mated to the large King Demon's pattern with an adapter spacer. Other than the heads and intake, the combination was identical. What were the Chapman's worth? Our 470 cranked to the tune of 774 hp at 6,700 rpm, and 667 lb-ft of torque at 5,900 rpm. No, we didn't sneak on a supercharger or nitrous. The Chapman heads just cooked the books on anything we'd seen from an engine of this type, shattering the power level of our monster iron heads by 132 hp and 56 lb-ft of torque. Are they really that good? We used these heads in this same combo in a national engine-building competition, taking on some of the biggest names in the business. Our 470 out-horsepowered every competitor in the game, be it Ford, Chevy, or Mopar, including Hemis. Yeah, the Chapman's deliver the goods.

MP/Chapman Head SpecificationsStage VI 260Stage VI 285 MWPart numberP4876383P4876386Intake portProductionMax Wedge Large PortIntake valve size2.{{{200}}}-inch2.250-inchExhaust valve size1.810-inch1.810-inchValve length5.400-inch (+.540)5.400-inch (+.540)Intake port volume260cc285ccExhaust port volume84cc84cc MP/Chapman Head Flow (Advertised)Stage VI 260Stage VI 285 MW8LiftIntakeExhaustIntakeExhaust.{{{100}}}"71557755.200"157112151112.{{{300}}}"230177220177.400"290211283211.500"325233330233.{{{600}}}"351242364242.700"351252375252.750"260381260