Bigger is better, baby, and the hot rodder's battle cry is nowhere more in vogue than with the part-time engine-builder hooked on big-lift cams. But there's much more to the science of lobe crafting than just picking a big valve lift number and stuffing it in the engine. Camshafts may be simple-looking devices, but the cam is actually the brain for your engine. The heads determine the flow capacity, but the cam is what really determines the ability to make power. If you haven't yet run through the cam basics story, do that first. Once you've got a grasp of the terms and basically how a cam works, this story will make a lot more sense.

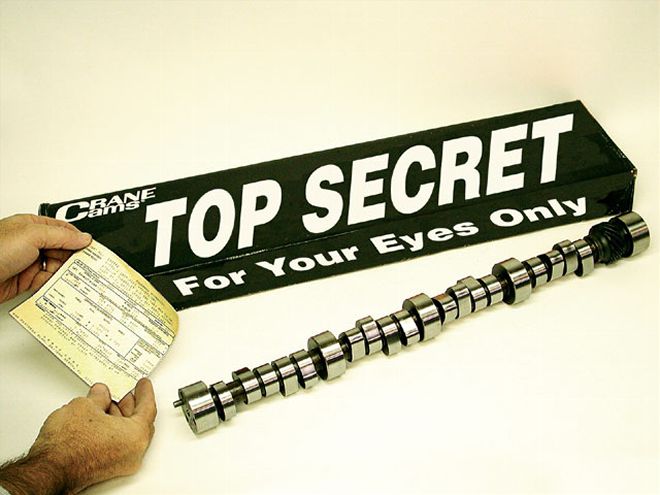

Roll OnThe new car companies were the ones who made hydraulic roller cams popular. Ironically, the OEM companies moved to hydraulic rollers in an effort to reduce internal friction and improve fuel mileage. We're going to show you why these cams will help you make more power. It has to do with the way the roller cam contacts the lobe of the cam. To begin with, flat tappet cams are generally built out of cast iron, specially ground, hardened, and sent out the door. This is why they are relatively inexpensive at around $100 to $150 apiece. Roller cams must be built out of hardened steel, and most current street rollers now come with an iron gear installed to make it compatible with a stock distributor gear. This better material and extra machine work all costs money. That's why roller cams are two to three times as much as a flat tappet. Plus you have to add in the cost of roller tappets and the attendant accessories. We'll deal with all those variables in the story on converting to roller cams.

So why go through all this extra effort and expense? Because roller cams can make good power, and they do so while maintaining decent street manners and throttle response. The trick is in some interesting physics that occurs when you employ a roller tappet. First, let's look at a flat tappet style cam.

Flat tappet cams are limited in velocity by the diameter of the lifter. Basically, you can only smack open a valve with a flat tappet lobe so quickly before you run the edge of the lifter into the lobe. The larger the lifter diameter, the quicker you can move the lifter. Small-block Chevy cams are limited with a relatively narrow lifter that's 0.842 inch in diameter. This limits the amount of lift you can generate with a given number of degrees of duration. In other words, to make more lift, you need to add duration. The problem with added duration for street cars is that this moves the peak torque rpm point higher in the rpm band, hurting low-speed torque and making the engine less streetable.

With a hydraulic roller camshaft, the limitation is that the roller cannot accelerate as quickly off the seat compared to a flat tappet lobe. However, as lift increases, the roller can move the lifter at a higher velocity, creating more lift sooner in the mid-part of the opening and closing sides of the lobe, generating more lift without radically increasing the duration. Our comparison chart of two cams with the exact same duration at 0.050 makes this point more clear. Basically, you're able to generate about an additional 0.030 inch of valve lift with a roller cam with the same duration at 0.050 numbers as a flat tappet hydraulic.

Of course, this also means you will need an engine combination that can take advantage of this. A relatively stock 350ci engine with weak heads and a near-stock exhaust and low-rise intake will not benefit nearly as much from a more aggressive roller cam. Conversely, a 383 with a good set of heads, compression, excellent intake, a 750-cfm carburetor, and a set of headers with a free-flowing exhaust is a combination that could take advantage of a hot hydraulic roller cam.

When we talk about acceleration rates and high lifter velocities, it's worth mentioning that a good set of valvesprings are also essential to ensuring you make all the power the cam can provide. If you remember from last month, we tested a 454 H.O. big-block Chevy that had always frustrated us in trying to make decent power with that hydraulic roller cam-equipped engine. The simple addition of a better set of valvesprings was worth power across the entire power band of the engine, peaking with an over-20hp increase at the top. This was strictly the result of improved valve control, which is a result of the higher valve velocities created by a hydraulic roller cam. The point here is that all these pieces fit together to create the power.

How much power is a hydraulic roller cam worth over a flat tappet? As this story is written, we're in the middle of testing a hydraulic roller cam in our Chevy 350 H.O. engine compared to previous tests with a flat tappet cam. The cams are not exactly the same at 0.050-inch tappet lift, but they're close. You can read the story in this issue, but the hydraulic roller was worth over 25 hp more at the top, while torque improved throughout the entire rpm curve from 2,500 to 5,800 rpm. When you can pick up power all the way through the rpm curve, you're definitely going to run faster. What's even more impressive is that this engine responded this well with only a pure stock pair of iron Vortec heads fitted with a set of Comp's new beehive valvesprings.

ConclusionThe beauty of a flat tappet hydraulic cam is that it is simple, inexpensive, and if matched properly with the engine combination, will offer up excellent power. But if you're looking for that next level of street performance, hydraulic roller cams are the hot ticket.

Roller Vs. FlatThis is an intake lobe comparison of a flat tappet hydraulic versus a hydraulic roller lobe, with the same duration at 0.050 numbers for the flat versus roller camshafts. There are several interesting things going on here. The most obvious point is that the roller cams offer significantly more valve lift. The Comp hydraulic roller generates 0.026 inch more maximum valve lift than the Comp flat tappet hydraulic while the advertised duration is 8 degrees longer. The Crane roller also offers the same duration at 0.050 with almost 0.050 inch more lift than its comparable flat tappet cousin.

Perhaps the most critical point in this discussion is the duration at 0.200-inch tappet lift numbers. Note that the Comp hydraulic roller cam offers 8 more degrees of duration (145 vs.137) between the 0.200-inch lift points on the opening and closing sides of the lobe. The hydraulic roller's added duration keeps the valve open longer compared to the flat tappet, which means the intake port can stuff more air into the cylinder. In essence, it's like installing a longer duration camshaft without sacrificing the lower-speed torque of a longer advertised duration cam.

It's also worth noting that the hydraulic roller's advertised duration numbers are longer than the flat tappet lobe. This reveals the net effect of the flat tappet cam's higher initial acceleration rate off the seat. We'll get more into that with the next sidebar, but you can see it here in the numbers since the hydraulic roller cam's advertised duration is 8 degrees longer than the flat tappet even though they offer the same duration at 0.050-inch tappet lift. The roller's slower initial acceleration is also reflected in the "HIT" numbers. This is not always true, however. Some Crane hydraulic rollers offer very short advertised duration numbers.

The "HIT" column refers to hydraulic intensity, which is a figure derived by subtracting the duration at 0.050 number from the advertised duration number. This number relates to how quickly the lifter accelerates away from the base circle. In other words, if the lifter accelerates more slowly away from the base circle, this requires more degrees of duration between the opening checking point and 0.050-inch lifter rise. Most hydraulic flat tappet cams accelerate quicker off the base circle than hydraulic roller cams.

Cam Adv. Dur. @ Dur. @ Lift w/ HIT Dur. 0.050 0.{{{200}}} 1.5 Comp XE268 268 224 137 0.477 44 Comp XEHR276 276 224 145 0.503 52 Crane 290 290 234 148 0.494 56 Crane HR296 296 234 157 0.540 {{{62}}}The Cost Of PowerIt always costs extra to make more power, and hydraulic roller motors are no exception. The following chart outlines the price difference for three small-block Chevy cam kits. The first is a Comp hydraulic flat tappet cam kit, the second is a hydraulic roller cam kit for a block configured stock with hydraulic roller tappets, while the third is a Comp retro-fit K-kit that allows you to use hydraulic roller tappets in a pre-'86 engine. As you can see, the price increases dramatically with the complexity of the kit. You would also want to run good roller rockers with this kit, which is an additional $230 to $280. All parts were priced through www.summitracing.com.

Cam and kit K-Kit PN Price Xtreme Energy hyd. flat tappet K12-242-2 $310 Xtreme Energy hyd. roller, OEM style K08-423-8 670 Xtreme Energy hyd. roller, retro-fit kit K12-422-8 875