Performance Special thanks to Bob Mazzolini Racing (909/787-8783) for technical assistance with this engine buildup.

Chrysler's 440 is at least 15ci smaller than its GM and Ford rivals--but it still puts puts up adarn good fight. On Westech Performance's dyno, our 440 made more torque than any other engine in Car Craft's ongoing big-block engine showdown series, and came in just behind the big-block Chevy and Buick in max power output. The pugnacious Mopar serves as a fitting finale to our year-long marathon of similarly configured "real street" big-block builds, illustrating just how far improved today's streetable musclecar engines are compared to their classic '60s forebears.

Cam and Valvetrain

Once again, Comp Cams supplied an Xtreme Energy 274 flat-tappet hydraulic cam--an aggressive design featuring more lift per duration than old-tech musclecar-era cams. The "custom" version installed in this engine has a three-bolt "Hemi" timing-chain cam-sprocket snout in lieu of the single-bolt snout normally found on big-block Mopars. You'll probably be upgrading to a new roller timing chain anyway; the price for the safer three-bolt retention setup is about the same, so why skimp?

Camshaft Specifications

Part No.: 23-000-5

Grind: CRB 5445/286H-3 HY110 (custom)

Type: Hydraulic flat-tappet, three-bolt cam sprocket

Duration at 0.006-inch tappet lift: 274* int./286* exh.

Duration at 0.050-inch tappet lift: 230* int./236* exh.

Valve lift (1.60:1 rockers): 0.523-inch int./0.523-inch exh.

Lobe displacement angle (LDA): 110*

Installed intake centerline: 106*

Comp Cams offers shaft-mount

Chrysler aluminum roller rockers in the stock Chrysler 1.5:1 ratio as well as 1.6:1. Both cost the same, so we opted for the 1.6:1 set to gain a performance advantage. Mopar-style roller rockers should be used with hard-chromed shafts and special pushrods with a cup on their rocker-arm ends.

Cylinder Heads

This engine uses Edelbrock's new Performer RPM Chrysler 440 heads, which feature hand-blended valve-bowls and CNC port-matched 210cc intake ports and 70cc exhaust ports for optimum flow and maximum power production. Edelbrock kept the stock Chrysler intake and exhaust port locations, except for the exhaust flange location, which was moved outward 1/8 inch to permit "blind" exhaust bolt holes while maintaining adequate aluminum material thickness without compromising the water jacket size.

Oil and Water

The Chrysler oiling system is fairly reliable once you upgrade to a high-volume oil pump. Down as it was by 15 ci compared to our other big-block buildups, we sought to give the "little" Mopar all the help we could by adding a Milodon windage tray--a relatively inexpensive upgrade.

Rotating Assembly

Chrysler lowered compression ratios in the post-musclecar era by decreasing the piston compression distance instead of increasing chamber volume, so most streetable replacement pistons end up 0.090 to 0.154 inch down in the hole at TDC--terrible for quench! Only the '70-'72 Six Pack forging yields around 10:1 with near-zero piston deck heights. Dougan's bored and torque-plate-honed the engine 0.040-over because the usual 0.030-over pistons were on back-order. Dougan's also cleaned, decked, and align-honed the block; rebuilt the rods; hung the pistons on pressed pins; turned our forged crank 0.010-under; and balanced the rotating assembly.

Speed-Pro offers a premium file-fit plasma-moly 5/64-5/64-3/16 ring-set (PN R-9224) for standard, 0.030-over, and 0.060-over 440 Six Pack slugs. No file-fit rings are listed for a 0.040-over 440's 4.360-inch bore, but it turns out that this oversize is the same as a standard-bore Ford 429/460, allowing the use of a premium standard "Ford"-bore file-fit set (PN R-10246-05).

Our core's tired old stock harmonic damper had seen better days, so Westech upgraded to a TCI Rattler 2000 torsion vibration absorber. A pendulum absorber design, it controls amplitudes of crank vibration without fluids, elastomers, or friction materials. The neutral-balanced unit is designed for internally balanced Chrysler forged cranks like ours.

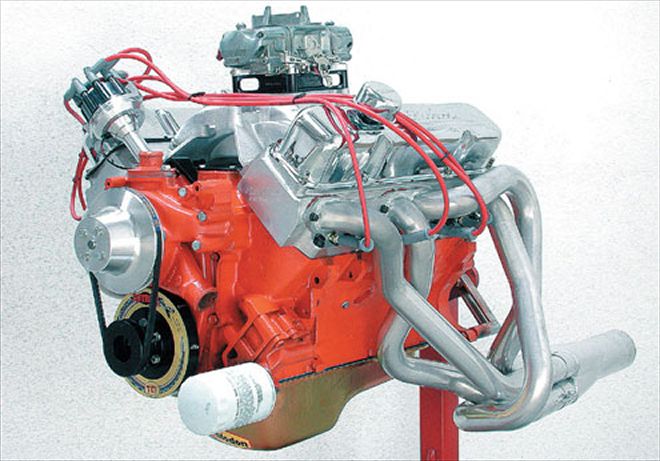

Induction, Ignition, Exhaust

We tested two different Edelbrock intakes fed by a Speed Demon 750-cfm carb. MSD's Pro Billet breakerless distributor was fired by Westech's standard dyno rig: an MSD HVC high-output coil and Digital 7 ignition. Hooker headers (2-inch primaries into 31/2-inch collectors) designed for '67-'70 B- and E-bodies exhausted the spent mixture. The engine ran best with 37 degrees of advance.

Test Results

With a 750-cfm Speed Demon carb, Edelbrock's Performer RPM intake ran best on Westech Performance's dyno with a Wilson Manifolds' four-hole 1-inch-tall closed spacer; the Torker II didn't respond better to any spacer design. Much stronger than the Torker II under 4,800 rpm, the RPM also generated slightly better top-end numbers.

Despite giving away 15-20 ci compared to the larger GM and Ford big-blocks, the Chrysler still churned out 535.5 hp at 5,300 rpm with the RPM intake, putting it in Third Place behind the 454 Chevy (542.3 hp) and the Buick 455 (555.3 hp with a 750 carb). In terms of hp/ci output, the Chrysler was right up there with the Buick at 1.20 hp/ci. But even though it had the shortest stroke and longest rods of any of our big-blocks, the Mopar also churned out more torque than any engine in this series, including the torque-monster 455 Pontiac.