You know, it wasn't all that long ago that replacement sheetmetal for your classic Mopar was pretty limited. Thankfully, companies like Auto Metal Direct have stepped up in a big way to provide an ever-increasing number of the parts you need to complete the car of your dreams.

Still, not every piece of sheetmetal is available for every Mopar, as some parts are just not practical to reproduce. And sometimes just a small area needs repair and you'd rather not have to replace the whole panel. Such is the case with a '72 Road Runner that we found at Muscle Car Restorations in Chippewa Falls, Wisconsin. MCR is relying heavily on AMD to provide the needed body panels, but there are a couple of small areas around the windshield frame where the best solution is to make your own repair patch.

This kind of repair is actually quite common on many restorations so this is a valuable skill to acquire. We chose this area around the windshield frame because of its compound curves and because it's a common problem area. Compound curves generally require the repair patch to be either stretched or shrunk and this one needs both.

One good thing about making your own patches is that this is one of those times that if you make a mistake there's no harm done. You just throw it away and start over. So there is little to lose and lots to gain. Go for it. You'll probably surprise yourself!

1. Rust damage around windshields and back windows is a fairly common occurrence. Fortunately, a repair patch can easily be built from scratch.

2. We're going to start with a piece of 18-gauge cold-rolled sheetmetal bent into a 90-degree angle.

3. Starting with the shrinker jaws like this set from Eastwood, begin to pull the part into a radius that matches the curve of the damaged area. The tighter the radius, the closer the shrink points should be on the metal. In this case MCR was only moving the metal about a quarter inch through the jaws at a time.

4. Check your work frequently as you go. You want to get to the correct shape with as few "shrinks" as possible to avoid work hardening the part, which could cause it to crack. As you can see, we're not quite there yet but getting really close.

5. Once the correct inside radius is achieved, now the top of the part can be stretched to form the downward radius from the roof to the A-pillar. Switching from shrinking to stretching is simply a matter of changing the jaws in the tool, making it a stretching machine

6. Stretching (or shrinking) a curved area will naturally produce flat spots that will need to be tapped back into shape with a curve-faced hammer.

7. At this point you can remove the damaged area using a cutoff wheel being careful to leave all of the roof area intact.

8. In this case, some spot welds also need to be drilled.

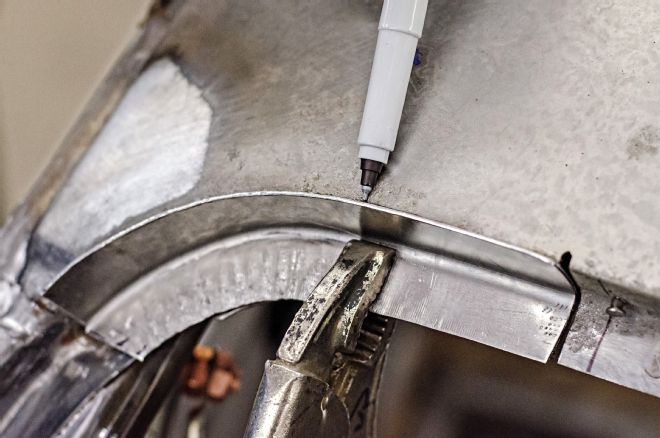

9. & 10. With the new piece trimmed to length and clamped in place, the shape of the roof contour can be drawn on the upper section to provide a guide for grinding the part so that it just fits under the roof edge.

11. Before the new part is welded in place, MCR insists on applying some SEM Copperweld weld-through-primer to prevent rust.

12. A little additional hammer work may be needed to get the part to fit perfectly after it's been tacked in place.

13. Even though an area like this is fairly resistant to heat warping, do not attempt to run even a short weld bead. Instead, keep tack-welding in between the tack welds until you have filled in all the gaps. Then, grind the weld smooth, avoiding the original roof metal as that can get thin very quick.

14. All that remains is to replace the spot welds and the repair is complete.

15. In case you don't have an extra $1,000 to purchase a pro-level foot operated shrinker/stretcher, the guys at Muscle Car Restorations say the ones that you can get from Eastwood for $200 will work just fine for up to 20-gauge sheetmetal.

16. Harbor Freight has a handheld manual spot welder for about $200 that will do a fine job with the metal thicknesses you'll encounter with this type of work. It's totally manual with no power adjustment so you better practice a bit before you commit to anything important, but it will produce a factory weld once you become proficient.