The technological advancements in automotive refinishing over the last couple of decades have been mindboggling. Having spent a little over a decade of my youth in the paint and body equipment sales industry, from the late '70s to late '80s, it was only natural that I became a paint- and bodywork hobbyist myself, repairing and painting all of my hot rod projects, motorcycle projects, and a fair amount of my everyday drivers in my home garage (and sometimes driveway). Back then the industry had just recently advanced from the old-style Nitrocellulose Lacquers to the much-improved Acrylic Lacquers and from Synthetic Enamels to two-component Acrylic Enamels—providing easier application, improved gloss, and longer life. As the years passed and I moved on to the auto parts business and then on to automotive publishing I continued performing all of my own body- and paintwork—all the while staying within my comfort zone of acrylic lacquers and enamels. As the years passed the "advanced" paint formulations I'd grown accustom to also become obsolete and much harder to come by. Acrylics were replaced with Urethanes and thanks to the tree huggers and the EPA onward to the low-VOC (volatile organic compound) high-solid versions and waterborne finishes of today.

Recently, I learned of yet another revolutionary new automotive finish developed for the marketplace—peelable rubber-based coatings. That's right, now there's a unique strippable rubberized coating that can be easily applied over nearly any foundation and can remain in place indefinitely, or be removed by simply peeling it off! It was no surprise to me to find that our friends at the Eastwood Company are an industry leader in offering this revolutionary new rubberized coating technology with their product called ElastiWrap. ElastiWrap removable rubber coating is available in a large selection of factory packaged colors or you can intermix the colors for a nearly unlimited choice of colors and shades—they even offer clearcoats and a pearlizer coating for a custom finish too. Upon application you can keep ElastiWrap on the surface indefinitely or if you become tired of the color, you can just peel it off and spray on a different color. That's right, you just peel it off. It doesn't harm the painted or bare surface underneath. In fact, it protects surfaces from UV damage, scratches, and corrosion. Spray the high-build rubber coating on an unfinished surface to protect it until it's ready to paint. Spray it directly on glossy clearcoats, paint, unfinished metal, and other surfaces for color and protection.

I can definitely say there will be an ElastiWrap project in my future but until then I got a real good idea of how the ElastiWrap system works and how easy it is to apply by watching it be applied to a Model A roadster pickup. Check it out here for yourself and then hit the Eastwood Company website and check out ElastiWrap kits and more info on all the color choices and options available.

01 Prepping a vehicle for a coating of ElastiWrap is pretty straightforward. All it takes is a clean surface free of dirt, grease, grime, and loose paint flakes, and for any portions of the vehicle you don't want coated to be masked to avoid overspray.

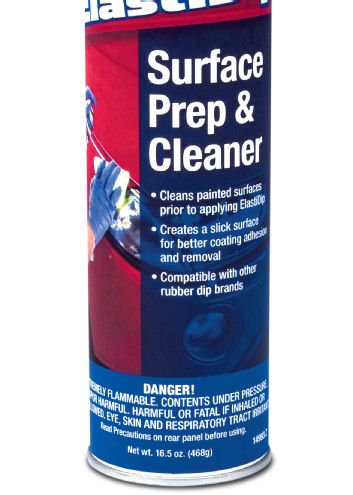

02 For proper application (a combination of adhesion and removability) the surface to be coated should be washed and dried, then followed by the application of Eastwood ElastiWrap Surface Prep and Cleaner, PN 14933Z. This is an important pre-application (spraying, brushing, or rolling) step.

03 Apply Eastwood ElastiWrap Surface Prep (PN 14933Z) one panel at a time according to the instructions on the container.

04 After prepping a panel, wipe the surface off with a clean, dry rag to help lift off any contaminants. The Surface Prep will leave a thin coating of special wax on the cleaned surface that will aid future removal. For heavily soiled surfaces it's recommended that you wash the surface with Eastwood PRE painting prep (PN 10041Z) prior to using the ElastiWrap Surface Prep.

05 ElastiWrap high build, removable rubberized coating is available in spray cans, quarts, and gallons, and Eastwood also has everything you'd need to prep and apply it too. ElastiWrap can be applied by either brush, roller, or by spraying it via HVLP guns as well as with an all-in-one Turbine gun system that doesn't even need an air compressor. Eastwood also offers ElastiWrap in kit form, which contains 3 gallons of ElastiWrap, a Turbine spray gun, prep spray, and more; everything needed to coat one standard size car.

06 For this application Olive Drab Green was the color choice. Two gallons should be sufficient for the diminutive roadster pickup cab and bed.

07-08 Prior to loading up the spray gun, stir or shake ElastiWrap to ensure the mixture/color is uniform. ElastiWrap is packaged ready-to-spray but if for any reason it does need to be thinned use ONLY mineral spirits and no other solvents.

09 The guys decided to apply the ElastiWrap using the Eastwood electric Turbine Paint System (PN 14878) but the coating can be applied using a standard HVLP spray gun equipped with a 1.4- or 1.8mm nozzle/needle assembly.

10 Upon making sure everything they didn't want covered in ElastiWrap or its overspray was completely masked off, the spray process was begun at the bottom left of the cab's cowl section.

11-12 The first coat is a light "tack" coat allowing a full 15- to 20-minute flash time. The tack coat will aid in holding a second light coat with less chance of sagging or runs. After a second light coat wait another 15 to 20 minutes before proceeding. The first two-coat foundation should flow out and level itself before additional coats are applied.

13 Though full color coverage was achieved with the first two coats, it's critical to apply at least three additional coats. (For optimal strippability a minimum of six coats is recommended, especially if using a standard automotive-type HVLP gun.) Once the initial two coats have been applied and allowed to flash begin applying full coats to achieve optimum film thickness (3 to 5 mils), allowing 10 to 15 minutes between coats.

14-15 Since the cab and bed were sprayed as separate units they followed the exact same process as they did with the pickups' cab.

16 They started with two light coats, allowing 15 to 20 minutes of flash time between each—then followed up with the additional heavier coats just as was done on the cab. Once spraying has been completed the spray equipment can be thoroughly cleaned using mineral spirits.

17 Once the bed was completed and allowed to dry for 20 minutes or so it was carefully set into place on the chassis behind the cab.

18-19 In regards to the masking of the vehicle, if any hard lines were made using masking tape (on a two-tone job for example) it's best to pull the tape while the ElastiWrap is still wet. If the coating has begun to dry carefully use a razor to cut along the edge so the coating won't peel away with the tape. In most cases a vehicle can be put back into service as soon as the final coat has dried and all masking removed. For best results wait at least 3 hours (at 70 degrees) for it to be totally dry.

20 And here's the finished product. The Olive Drab looks right at home on the rpu and the ElastiWrap finish flowed out nicely. At this point it'd be prudent to wait several days for the coating to thoroughly dry before any heavy handling and/or reassembly takes place. I have to admit, the pickup looks great. I'm already picturing using ElastiWrap in a few specialized circumstances on my own street rod projects for sure.