You may remember last month we pretty much wrapped up the chassis section of the Ford Model A coupe project at Hot Rods By Dean, assembling the Total Cost Involved Engineering chassis with the exception of the front suspension. This month we'll be installing the body on the chassis and hooking everything up.

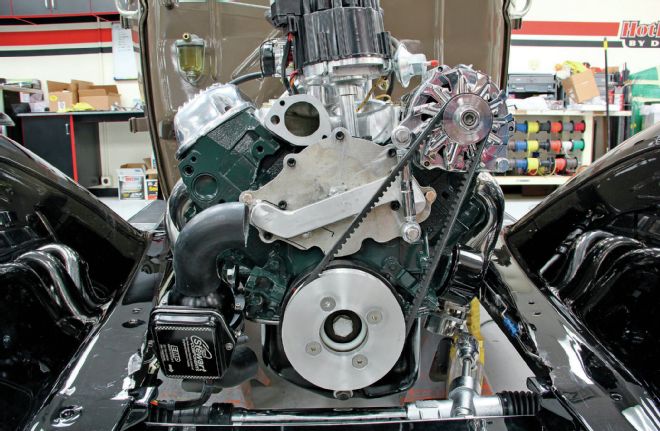

Speedway Motors not only supplied the 302 Ford engine, but the stainless block hugger headers, mufflers, and 2-1/2-inch exhaust pipe kit too, as well as the alternator, radiator, and engine mounts. Ah, the engine mounts. In order to make this project a true, simple, body swap exercise, the body had to remain unmodified. That meant keeping the stock firewall and gas tank, which in turn meant moving the engine forward. The crew at Hot Rods By Dean had to think creatively to achieve this, opting to flip the headers side for side and fabricate new mounts for the block, while retaining the mounts on the powdercoated frame, and fabricate a cradle to mount the Hughes Performance–supplied C4 trans to the TCI Engineering crossemember. This all resulted in the engine sitting far enough forward to clear the firewall, and with the stock water pump replaced by a Stewart electric pump and some fabricated plumbing, the Speedway radiator fit in its stock location too.

While this project was intended to celebrate TCI Engineering's 40th anniversary, it also coincides with the company's announcement of its new Dual Warranty, comprising a 6-year/60,000-mile warranty on wear-and-tear items, and a lifetime warranty on TCI Engineering–manufactured parts. Wear-and-tear items include kingpins, steering U-joints, shocks, coil and leaf springs, Vega steering box, proportioning valves and check valves, and headers, but exclude brake rotors, pads, drums, and shoes. This is an industry first that we're aware of, and shows the company's commitment to standing behind its products.

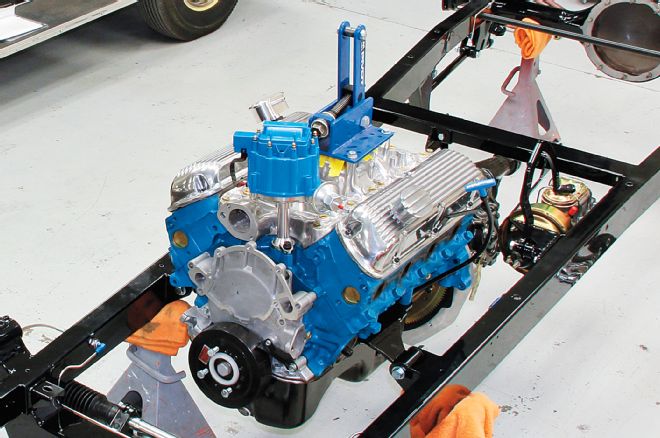

1. Speedway Motors supplied the 302ci small-block Ford crate engine, as well as the finned valve covers, while the C4 trans came from Hughes Performance. At first the engine and trans were mounted on the Speedway-supplied mounts and the TCI Engineering trans cradle, but it was obvious it was too far rearward.

2. With new mounts fabricated and an extension to the TCI Engineering trans cradle, the engine cleared the firewall and the body could be dropped into place. But now the water pump interfered with the radiator!

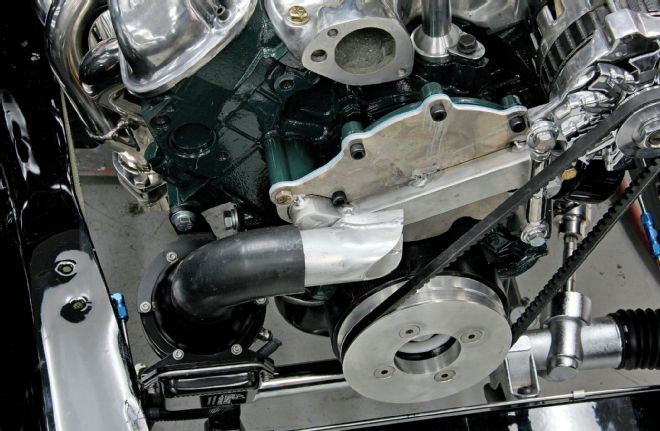

3. With the stock water pump housing removed (and the engine now painted green!) a fresh gasket was installed ...

4. ... and this fabricated blanking plate and tube system bolted in place. Note the tube has been fabricated to clear all the stock mounting bolts.

5. Not finished but well on the way, this tube will feed water from the electric pump to the new tubing leading to each side of the block.

6. Jumping ahead slightly, but here's the finished Stewart electric water pump installation, water coming from the radiator lower neck via a stainless tube under the oil pan.

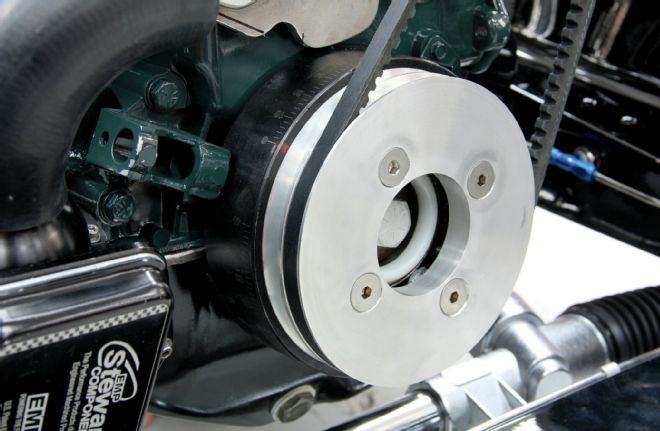

7. This double grooved aluminum crank pulley was machined up to drive the Speedway-supplied alternator, which is mounted on an adjustable bracket as there are now no other belt-driven components.

8. Swapping the headers side for side allowed them to dump ahead of the engine mounts ...

9. ... instead of behind them as designed. Luckily the small-block Ford has equally spaced ports and symmetrical mounting bolts.

10. Livermore reused the Model A steering column, eliminating the steering box and adding U-joints just below where the column exits the firewall. The two rods that operated the spark advance and mechanical throttle were retained and one is now used for the headlight switch.

11. Looking from underneath, you can see the route the steering linkage takes from column to rack with two support bearings. The new engine mounts are clearly visible too.

12. While the CPP brake booster and master cylinder fit the frame as TCI Engineering designed, Livermore modified the stock Model A pedal to operate it. Note too the extended cradle to mount the trans. This gives a good idea just how far forward it was moved.

13. No need for a new interior, the original wasn't even removed, except for the seat base and front floorboards.

14. New welding was fitted, and rubber pads in place of the wooden body mount blocks under the subrails.

15. Here's the reason Livermore wanted to wait until the fenders were on prior to installing the front suspension. The inner pivot of the upper A-arm and the fender brace want to occupy the same space.

16. With the upper A-arms in place, Livermore's solution was to modify the fender brace as shown, allowing clearance yet still supporting the fender and headlight bar.

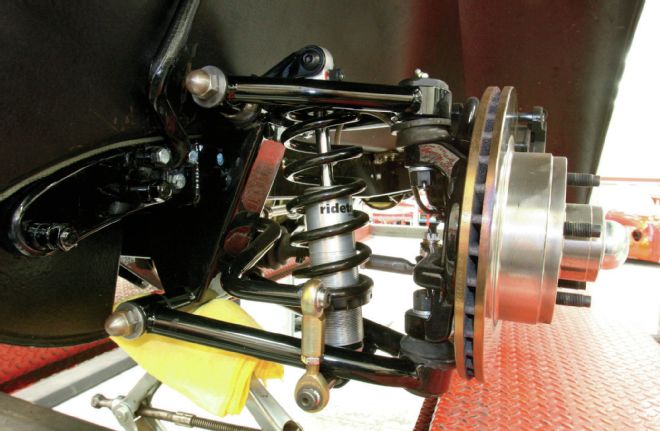

17. The TCI Engineering IFS fully installed, complete with antiroll bar and nitrogen-filled RideTech coilovers.

18. The IFS viewed from the rear, showing the steering rack.

19. Speedway motors supplied a 2-1/2-inch stainless exhaust kit, with which Livermore fabricated this single-sided twin system. It not only looks great but avoids placing heat around the brake booster and master cylinder.

20. The exhaust dumps out through a pair of bell-mouth tips below the rearend.