Most cars have enough room to accommodate blower drives but a design quirk common to all 1935-37 Ford passenger cars makes it impossible. The Cliff Notes version goes like this: according to Henry Dominguez in his biography, Edsel Ford and E.T. Gregorie, in a bid to increase rear passenger comfort for the 1935 models a Ford engineer named Larry Sheldrick slid the rear seat forward. And to preserve the front-seat space he had to move it and everything else to the grille forward by the same amount. But for whatever reason he didn't move the front axle forward as well. Though the 1935-40 Fords are visibly bigger than their 1933 and 1934 counterparts they all ride on the same 112-inch wheelbase.

That discrepancy makes the radiator and grille overhang the front wheels (until 1934 when Ford mounted its radiators directly over the axle centerline, the key element to those cars' gracefulness). But this change made the body appear to want to roll over the front wheels, as E.T. "Bob" Gregorie (who didn't work on the 1935 or 1936) lamented in Henry Dominguez's biography.

To minimize the overhang, Ralph Roberts and John Tjaarda at Briggs Manufacturing compromised by recessing the firewall so the engine could come back a touch. Then they jammed the grille and radiator against the engine. The nose still overhung the front axle but not quite as miserably as it could have.

The flaw carried through to 1936 but that year the designers modified the upper radiator tank so they could drop the hood to meet a lower, pinched grille. It didn't correct the problem itself but it minimized the visual impact that the overhang had on the car.

Of course that's cold comfort for our man Grange. His blower wouldn't fit come hell or high water. So he asked Shawn Seifert and Neal Kurschner at Tin Element in Loveland, Colorado, to solve the problem.

Rather than recess the firewall to push to achieve the necessary clearance they pushed the radiator and grille forward. Of course that increased the overhang. So they did a little more of what Briggs' designers did on the 1936: they lowered the grille and leaned it back just a touch more.

Those seemingly small changes had a butterfly effect of their own. The fenders looked as if they ended abruptly. The splash panels no longer reconciled the gap between the fenders and grille. Neither the grille fit the hood (a yawning gap opened at the back of the grille) nor the hood fit the cowl (too short). And the hood—it's fruitless to explain the ways it no longer fit.

So the boys did what they do best: They started cutting and bending tin. All told they modified every panel ahead of the firewall to accommodate the radiator and grille's new position. What follows isn't a step-by-step explanation as to how they did it as much as a general idea of what they did.

In the end Grange got just what he wanted: a 1936 Ford with a supercharged Flathead. Though the path to get there is a little unorthodox it fulfilled a need with the minimum fuss—minimum being relative of course. But it works and Grange is pleased as punch.

1. Shawn Seifert and Neal Kurschner moved the radiator and grille forward to achieve sufficient pulley clearance. The gap between the grille and hood hint at how much they pushed down and tilted back the grille.

2. Dropping the grille meant extending the fenders by about the same amount as shown here. What's less obvious was how they recreated most of the filler panel between the grille and fenders, a job made exponentially more difficult by its compound curve.

3. Rather than create the horn openings from scratch Seifert and Kurschner extracted the ones from the original filler panels and grafted them to the new panel.

4. Extending the hood made it wider than the cowl. Seifert and Kurschner pie cut it over its entire length, which narrowed it to fit the cowl. The green tape represents the degree they needed to angle the grille top to meet the hood.

5. Rather than make the hood sides fit, Seifert and Kurschner extracted the critical elements and grafted them to a scratch-built hood.

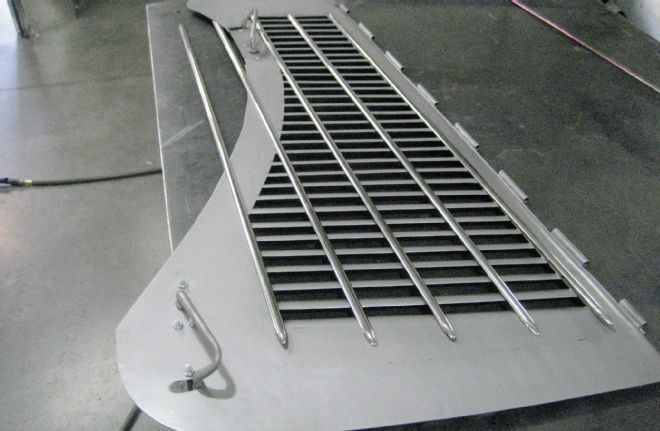

6. They used only five of six louvers and the latches and made the longer ones with custom dies in a Pullmax reciprocating hammer. More than follow the hood shape they offer potentially greater airflow. Seifert and Kurschner also cut down trim spears for the lower pieces.

7. Though it juts out another 2 inches at the base and about 1-1/4 inch at the top, you'd have to compare Grange's car side by side with a stock-proportioned '36 to tell the difference. The '41 bumper's greater arch masks the longer nose and its lower height conceals the extended fenders.