Having the right tool for the job can be paramount when it comes to properly repairing damaged sheetmetal and bodywork. Obviously, possessing the proper skillset is equally or perhaps even more important, but we can’t turn you into a metal man overnight. What we can do, however, is show you some tools we’ve found that make repairing, restoring, and customizing that old truck just a little bit easier.

I have to admit that I’m a bit of a tool junkie, and if you’re anything like me, you’ll dig the assortment of stuff we’ve put together. Some of the items, like the HTP Quick Spot II, are more wish list than real world for us, while some are tools that every home shop shouldn’t be without. All of these would not only make a truck build that much easier, but would help produce a better result, of which I could use any help I can get!

So whether you’re a body guy from the days of lacquer and lead or you’re more comfortable with a hammer and nails than a hammer and dolly, there’s something for everyone. I know that a tool as simple as a copper plate with a couple magnets glued to it has made my life a lot more enjoyable when it comes to welding sheetmetal panels together or filling holes. Who knew something so simple would be so effective? Hopefully you guys can glean something from this little collection as well.

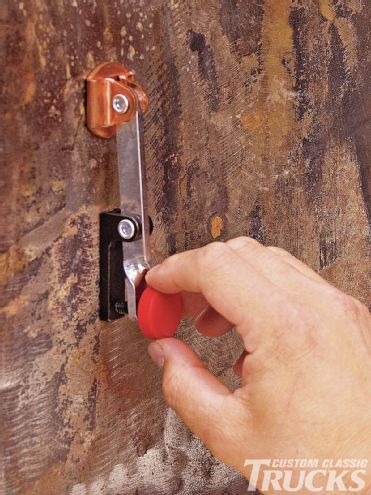

1. Blind holders are great for temporarily holding panels in place during fabrication. A 3⁄16- or 1⁄8-inch hole drilled through both panels is all that’s required for the fasteners to attach. With a grip range up to ¼-inch and 20 pounds worth of holding power, they’re strong enough to support almost any panel job.

1. Blind holders are great for temporarily holding panels in place during fabrication. A 3⁄16- or 1⁄8-inch hole drilled through both panels is all that’s required for the fasteners to attach. With a grip range up to ¼-inch and 20 pounds worth of holding power, they’re strong enough to support almost any panel job.

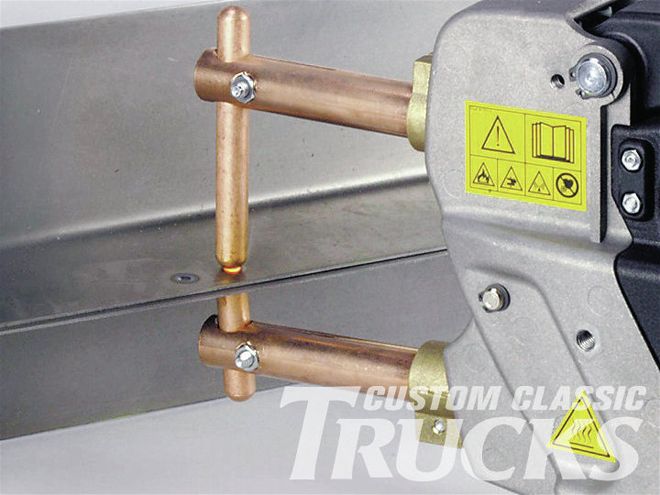

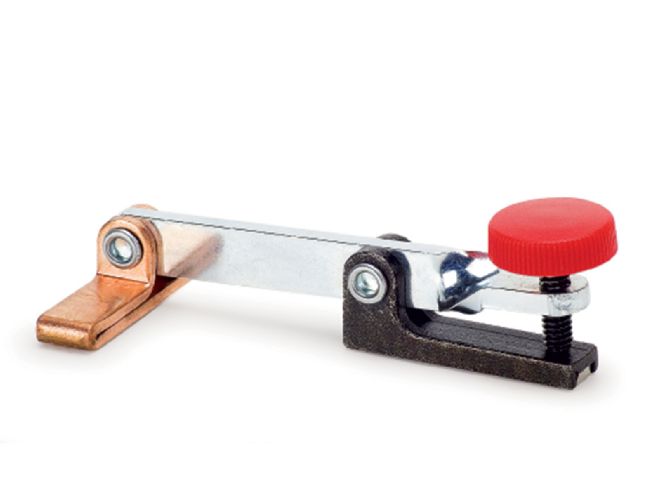

2. Another great way to position panels when butt welding is by using Intergrips. These panel clamps make it easy to position flat or curved panels for precise, edge-to-edge and surface-to-surface alignment, leaving an ideal 0.040-inch gap for full weld penetration. Simply clamp the panels together, tack weld, and remove for final welding, resulting in a clean butt weld that requires little grinding and is less likely to trap moisture.

2. Another great way to position panels when butt welding is by using Intergrips. These panel clamps make it easy to position flat or curved panels for precise, edge-to-edge and surface-to-surface alignment, leaving an ideal 0.040-inch gap for full weld penetration. Simply clamp the panels together, tack weld, and remove for final welding, resulting in a clean butt weld that requires little grinding and is less likely to trap moisture.

3. Sure, cutting metal can be done with a cutoff wheel and a pneumatic grinder, but there are much better ways to get the same job done. The most versatile, simplest, quickest way I’ve found to cut anything from 20-gauge sheetmetal to ¼-inch plate is by using a plasma cutter. This MicroCut 301 from HTP has served me well for many years and has handled any cutting chore I’ve thrown at it. Its compact, lightweight size, thanks to advanced inverter technology, doesn’t match the punch that it packs with an infinitely adjustable cutting amperage from 5 to 25 amps using 220 volts.

3. Sure, cutting metal can be done with a cutoff wheel and a pneumatic grinder, but there are much better ways to get the same job done. The most versatile, simplest, quickest way I’ve found to cut anything from 20-gauge sheetmetal to ¼-inch plate is by using a plasma cutter. This MicroCut 301 from HTP has served me well for many years and has handled any cutting chore I’ve thrown at it. Its compact, lightweight size, thanks to advanced inverter technology, doesn’t match the punch that it packs with an infinitely adjustable cutting amperage from 5 to 25 amps using 220 volts.

4. Factory-looking spot welds for that perfect restoration or custom build are now easy and affordable thanks to HTP’s Quick Spot II. Capable of producing 6,000 amps via 220-volt input, it provides factory-quality spot welds with virtually no warping and minimal finish work required.

4. Factory-looking spot welds for that perfect restoration or custom build are now easy and affordable thanks to HTP’s Quick Spot II. Capable of producing 6,000 amps via 220-volt input, it provides factory-quality spot welds with virtually no warping and minimal finish work required.

5. The micro-processor technology requires absolutely no welding skill to operate; simply select the thickness of the material to be welded, squeeze the handle, and the Quick Spot II does the rest.

5. The micro-processor technology requires absolutely no welding skill to operate; simply select the thickness of the material to be welded, squeeze the handle, and the Quick Spot II does the rest.

6. A good set of body hammers are a must have for anyone doing anything remotely related to sheetmetal fabrication, modification, or repair.

6. A good set of body hammers are a must have for anyone doing anything remotely related to sheetmetal fabrication, modification, or repair.

7. From left, a curved cross chisel hammer, cross chisel hammer, general purpose pick hammer, and a utility pick hammer will cover most bases when it comes to dinging out dents and rapping out repairs. The precision hand-ground and polished heads are heat treated before being mounted to either fiberglass or genuine hickory handles.

7. From left, a curved cross chisel hammer, cross chisel hammer, general purpose pick hammer, and a utility pick hammer will cover most bases when it comes to dinging out dents and rapping out repairs. The precision hand-ground and polished heads are heat treated before being mounted to either fiberglass or genuine hickory handles.

8. Of course you can’t just go around willy nilly banging those body hammers all over your fender without the proper tool in which to accommodate them. A decent assortment of body dollies go hand in hand with a set of body hammers and a combination of a heel dolly, toe dolly, curved dolly, and a general-purpose dolly will get 99 percent of the jobs done.

8. Of course you can’t just go around willy nilly banging those body hammers all over your fender without the proper tool in which to accommodate them. A decent assortment of body dollies go hand in hand with a set of body hammers and a combination of a heel dolly, toe dolly, curved dolly, and a general-purpose dolly will get 99 percent of the jobs done.

9. Shrink, stretch, and manipulate metal like never before thanks to Fairmount Tools from Eastwood.

9. Shrink, stretch, and manipulate metal like never before thanks to Fairmount Tools from Eastwood.

10. A dinging spoon is a handy little device that can be used as both a hammer and a dolly. Ding ridges smooth and level and spread a body hammer’s blows out over a large area to avoid unwanted marring on the surface of the metal.

10. A dinging spoon is a handy little device that can be used as both a hammer and a dolly. Ding ridges smooth and level and spread a body hammer’s blows out over a large area to avoid unwanted marring on the surface of the metal.

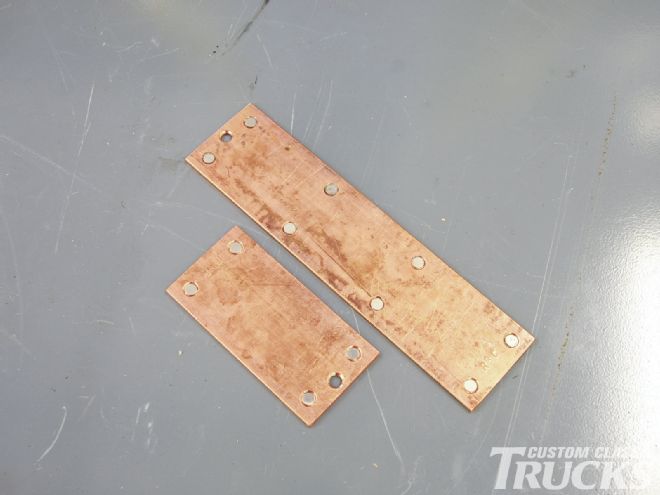

11. These simple little welder’s helpers from Eastwood have made my life so much easier recently that it makes me wonder how I ever got by without them.

11. These simple little welder’s helpers from Eastwood have made my life so much easier recently that it makes me wonder how I ever got by without them.

12. The copper acts as a backing support for the weld and the weld doesn't stick to the copper.

12. The copper acts as a backing support for the weld and the weld doesn't stick to the copper.

12. The copper acts as a backing support for the weld and the weld doesn't stick to the copper.

12. The copper acts as a backing support for the weld and the weld doesn't stick to the copper.

14. Eastwood's welder helper in its entirety.

14. Eastwood's welder helper in its entirety.

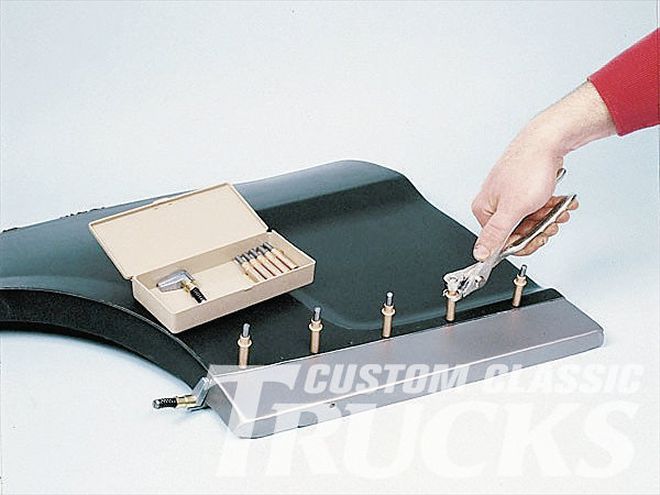

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.

15. This MIG stud welding kit from Eastwood gives your MIG welder the ability to quickly weld studs onto a sheetmetal panel that can then be used to easily remove dents using a slide hammer.