One of the biggest expenses incurred when building a traditional rod or custom, excluding paint, has to be stepping up to pay for chrome plating. There's no getting away from the fact that items like bumpers, grilles, and trim have to be chromed for that period look, though some items are available from the aftermarket already plated, such as bumpers.

One group of parts that always look good and period correct when dipped in the chrome vat are interior window frames. However, metal-finishing them after they're cut down to fit a roof that's been chopped is a time-consuming task. Completely disproportionate to the final appearance, they contribute a small part of the overall "look" that is only appreciated by those who have performed a similar operation. There's an easier way though, as we discovered when we talked to Spectra Chrome.

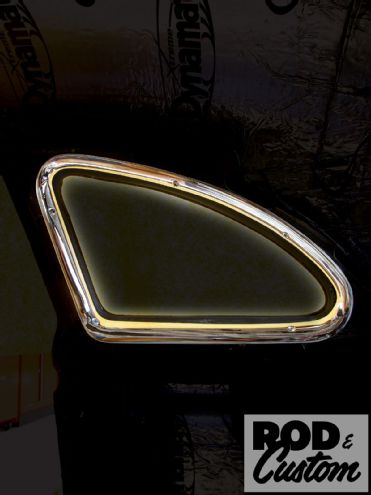

This is an electro-plating process as with traditional chroming, yet not strictly a painting process either. We were blown away when we witnessed the application firsthand, actually standing in the spray booth at Creations N' Chrome and watching as proprietor Gary Watson took the rear side window frames for our project '49 Chevy from gray primer to chrome-like appearance over the course of a day.

I chopped the rear driver side window frame some 10 years ago when I chopped the roof on the Chevy, but never got around to the other frames. These hold the interior window weatherstripping in place, and so are more than just cosmetic.

I chopped the rear driver side window frame some 10 years ago when I chopped the roof on the Chevy, but never got around to the other frames. These hold the interior window weatherstripping in place, and so are more than just cosmetic.

The advantage of the Spectra Chrome process is that up until the actual application of the final coats, the preparation of the parts is identical to any regular paintjob. The process can be applied over body filler, so long as a catalyzed primer is used. With this sanded to an 800-grit finish, just as you would for any basecoat/clearcoat application, a specially formulated white basecoat is applied, then baked on for two hours. This provides a high-gloss reactive surface to which the metal spray bonds, though it can absolutely not be touched once applied.

The metal spray process that follows consists of two water-based solutions sprayed simultaneously, using a dual-nozzle gun. These solutions mix and react as they exit the gun's nozzles, creating a fine mist of real silver that deposits over the basecoated surface. This is followed after another couple hours of drying time followed by a clearcoat. Transparent colors, such as candies, can be added to the clearcoat, though we opted for the straight chrome finish.

Once again relief cuts were made and the section bent and screwed in place. Apart from the initial hole, new holes had to be drilled in the perimeter frame for the mounting screws. This section had been damaged at some point, hence the poor fit along the lower section. This was repaired before final welding.

Once again relief cuts were made and the section bent and screwed in place. Apart from the initial hole, new holes had to be drilled in the perimeter frame for the mounting screws. This section had been damaged at some point, hence the poor fit along the lower section. This was repaired before final welding.

While much more environmentally friendly than conventional chrome plating, the obvious advantages for the end user are that not only can the process be applied over body filler, but the part to be plated doesn't even have to be made of metal! While at Creations N' Chrome we saw plastic and even wooden items being coated. Spectra Chrome advertises that the process is perfect for pitted pot metal parts, such as trim pieces, badges, door handles, and hood ornaments from '50s and '60s cars-and indeed it is, especially as these parts invariably can't be rechromed, but the possibilities are almost endless. How about molding your own grille from fiberglass and then having it chromed?

We were impressed with our finished window frames, though of course we had to cut them down and prep them before Creations N' Chrome could work their magic. Here's how they went from rusty stock parts to chromed masterpieces.