Louvers are cool-literally. They were invented to let hot air out of the engine compartments of race cars and other things that needed ventilation. Then hot rodders at the dry lakes found they were good for letting trapped air out of roadster bodies, making them more aerodynamic. So they punched louvers, lots of louvers, in decklids and other body panels. Louvers are functional.

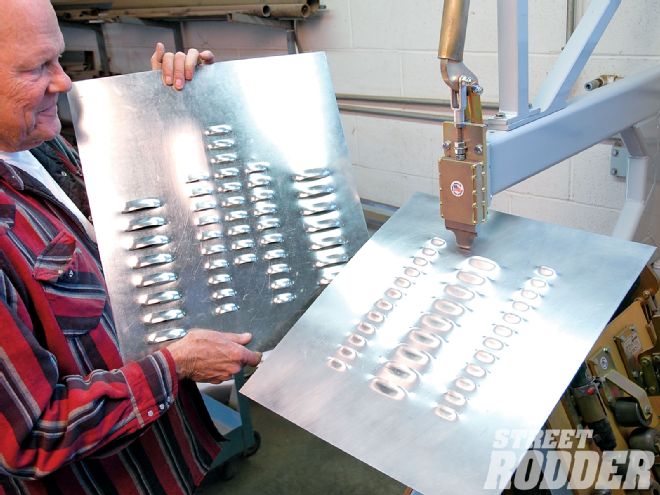

Dave Williams is obviously proud of his new Lowbuck louver press that you can use to punch 2-1/2- or 1-1/4-inch round-top "hot rod" louvers just like these in your home garage. Both sizes are patterned on the original Betz louvers from the '50s.

Dave Williams is obviously proud of his new Lowbuck louver press that you can use to punch 2-1/2- or 1-1/4-inch round-top "hot rod" louvers just like these in your home garage. Both sizes are patterned on the original Betz louvers from the '50s.

But louvers are also just plain cool looking. Along with lightening holes, carb stacks, multiple exhaust pipes, and big 'n' littles, they give any car a real racy, hot rod vibe. Especially when you put them in places where people don't expect, like splash aprons, tailgates, front or rear pans, roof panels, or even glovebox doors.

The only problem is where do you get them? You can't order them by mail, you can't make them yourself in your garage with the tools you've got, and you can't even get them done at a typical custom or body shop. You've got to find one of the few hot rod, race car, or machine shops that happen to have its own Lowbuck louver press. And these are few and far between because such presses have to be custom-made, they take up a lot of shop space, and punching louvers is a tedious, low-profit process for such shops. So the chances of finding one in your hometown are slim. If you do find one, getting them to take the time to lay out and punch a bunch of louvers in your body panels will probably involve scheduling, pleading, and a fair amount of green cash. Or, if the closest louver press you can find is in Detroit or Chicago, you can't very well package up your '40 Ford hood and decklid and ship them there to be louvered. Finally, for the first time, there is a practical solution, and its name, thankfully, is Lowbuck.

As a young teen, Davey Williams' first job was helping Stan Betz line up and punch louvers in hoods and other panels at his Betz Speed & Color shop in downtown Anaheim, California. Later he delivered Betz-mixed custom paint in his yellow, Kraft-style track T, and you can bet it was punched full of Betz louvers. Later on, after a stint of building hot rods for others, Williams invented and developed his own line of inexpensive, home-shop LowBuck metalworking tools, including flame cutters, tubing notchers, bead rollers, and so on. Somewhere along the line he inherited the one-off Betz 1-1/4-inch louvers press that makes cute little hot rod louvers you can find all sorts of places to use. He loves louvers and punches them in everything.

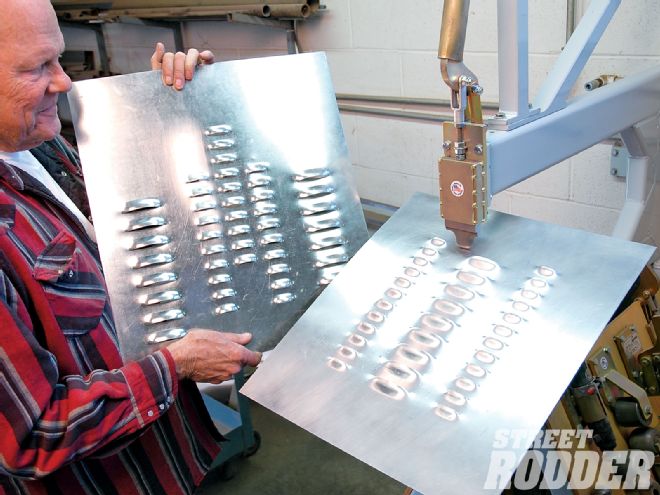

The louver punch is one of 10 different metalworking tools Williams makes to attach to the new 10-in-1 machine. It consists of the machine-formed die/punch unit on the right, and the lower cutter/receiver on the left. Surprisingly, louver presses don't need a formed female die. The shape of the male punch die determines the shape of the louver.

The louver punch is one of 10 different metalworking tools Williams makes to attach to the new 10-in-1 machine. It consists of the machine-formed die/punch unit on the right, and the lower cutter/receiver on the left. Surprisingly, louver presses don't need a formed female die. The shape of the male punch die determines the shape of the louver.

But it wasn't until just recently that he finally figured out how to make a Lowbuck, home-shop louver press that one, you can easily fit and use in your own garage, and, two, you can also afford. A few of years ago we told you about Williams' 10-in-1 Metalworking Machine (STREET RODDER, Nov. '07), which consists of a precision-machined head plate to which you can bolt various tools for punching, bead rolling, braking, planishing, or English wheeling sheetmetal. You make your own C-throat fixture out of 2x4, 1/4-inch-wall tubing to mount the tool head plate, to your own dimensions (normally 30 inches deep), attaching this to your shop wall and/or a floor stand. A round-top, 2-1/2 inches wide, "hot rod" louver die and press was one of the original 10 tools offered for this machine. And now Williams has just added the 1-1/4-inch Betz-style louver die, as well, that fits in the same press tool.

The photos will show how the tools are made and how they operate to punch louvers quickly and easily at home. If louvering is a prime objective, you'll want to make the C-throat arm as deep as possible to fit large body panels (like hoods). However, we must stress that, especially for louvering, this armature must not flex at all. The clearance between the back (flat) side of the louver die and the lower cutting block must be set and maintained at 0.005 inch. Williams' armature shown in the photos is bolted to the wall, solidly braced to the floor, and braced to an overhead beam. But that's the only caveat. This machine will punch louvers in mild steel up to 19-gauge (0.047-inch). We used 20-gauge for the sample processes shown here, and it's surprisingly quick and easy. Try it, and we guarantee you'll like it.