Although it's hard to imagine, every car on earth was once new. "Highly skilled" assembly line workers built it, some polyester-clad, furry-tongued salesman sold it, a happy customer bought it, and so began the cycle of life. We hot rodders often base projects on cars that, had they been flesh and blood, would have been buried and forgotten decades ago. What's more, we must address years of rust, crud, and numerous paint jobs before the rebuilding process can begin.

Unless you have the time to de-crud the car with 20 gallons of brush-on paint stripper and to grind out the rust and body filler with plenty of elbow grease, have a professional shop do it for you. There are three typical stripping techniques, each of which has its pros and cons. This story will help you decide which is best for your situation.

Dry-Pressure Blasting

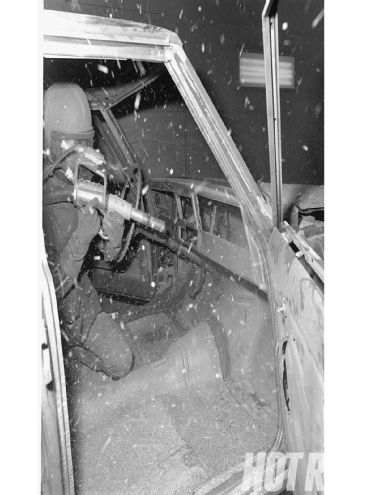

The '57 Chevy on the next page was taken to its bare elements by Strip-It Company using a two-step process. First, plastic media removes the paint and filler, then crushed glass eliminates the rust. Notice how bolt-in spacers separate the body from the frame to allow access.

As the name implies, dry-pressure blasting uses a jet of compressed air to propel a granulated cutting agent against a surface. It is at the point of contact between the airborne agent and the surface that things get critical. At this juncture, the amount of air pressure (in psi) and the type of cutting agent can mean the difference between a job well done and disaster.

If coarse sand were released at high pressure (say, 100 psi), the heat generated by the friction between the sand and the surface would cause the metal to expand and contract, resulting in a wavy surface-something that would take hours of corrective bodywork to fix. But if the sprayer were loaded with granulated walnut shells or plastic pellets, which are much lighter than sand, the air compressor could be at 30-50 psi because these materials require less force to set them in motion. But none of this is foolproof. If the spray gun operator sets the pressure too high, blasts the surface straight on, or dwells in one spot for too long, even lighter abrasives can generate enough heat to warp sheetmetal.

Although granulated walnut shells and plastic particles are as effective as sand for removing paint, Bondo, dried undercoating, and caulking, they don't produce the same results with rust because they aren't as hard as metal. To zonk rust, dry-pressure blasting offers two solutions: sand or crushed glass. With sand, the weight issue comes back to haunt us. Crushed glass, on the other hand, is lighter and only requires half the air pressure to do the same job as sand. Ironically, the glass is not an effective paint remover.

Although sand is the most brutish form of dry-pressure blasting, it's a quick, cheap way to strip cast iron or thick steel stampings. Just make sure the body panels don't get hosed along with the brake drums, door hinges, chassis parts, and axlehousings.

Is there a downside to dry-pressure blasting, besides the potential for warping? Well, all parts must be completely stripped. Upholstery, rubber, foam, glass, stainless trim, chrome brightwork, and plastic must go. And after a body shell is dry-pressure blasted, it seems as if no amount of vacuuming or cleaning can keep traces of the medium from popping up in nooks and crannies for years to follow. Also, crushed walnut shells leave a thin coating of oil that might foul your paint job, so a thorough chemical cleanup is mandatory.

Wet-Pressure Blasting

Notice the water on the floor as the '39 Ford body shell on the following page gets a baking soda wet-pressure blast at Drezek Environmental Stripping Systems. In addition to being a marvelous stripping agent, baking soda is biodegradable.

Wet-pressure blasting is similar in concept to the dry-pressure method except that the cutting agent is baking soda (sodium bicarbonate). Instead of compressed air, a stream of atomized water delivers the bicarb to the metal surface at 50-60 psi. The water eliminates dust and, most importantly, cools the surface being stripped, thereby prohibiting warpage. While we might assume that baking soda removes paint through some sort of chemical reaction, it works because the particles have sharp, crystalline edges that are hard enough to strip paint (including Imron) and rust. So while dry-pressure blasting requires two different cutting mediums, one for paint and one for rust, or must rely solely on risky sandblasting to get 'em both, the wet-pressure method eradicates paint and rust simultaneously.

The baking soda blast does no harm to window glass, headlamps, chrome plating, or stainless trim pieces. In fact, the process actually buffs and polishes these parts. This might not mean much to someone who wants to free the gutted shell of a '66 Chevelle SS396 from paint and rust, but wet-pressure blasting does facilitate small-scale paint and rust stripping on complete cars.

Ron Drezek tells us that wet-pressure blasting allows bodywork pros to remove one layer of paint at a time, which leaves the original factory zinc phosphate primer intact. And in cases where the primer has been lost to a previous restoration or destroyed by surface rust, the chalky white residue of the dried baking soda helps stave off oxidation for a few days, until prep work for the paint can begin. (Dried baking soda forms a hard paste that can be easily removed with a vinegar wash.) To ensure compatible paint adhesion, use soap and water to eliminate any traces of the residue before you apply the primer coat. The downside? Practically none, save for price, which is 15 to 50 percent more than that for the dry-pressure blasting.

Chemical Stripping

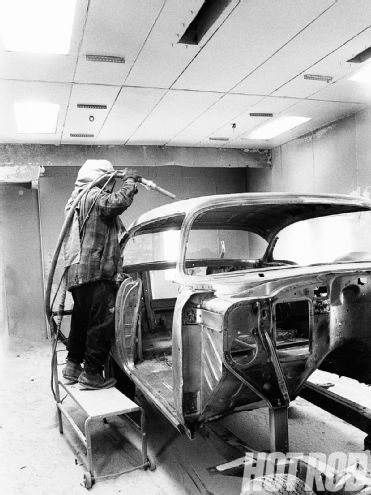

Chemical stripping is so effective that some projects are scrapped after the owner realizes just how much rust was present. Once the paint, Bondo, and rust were removed from this '57 Chevy (next page), most of the body looked like tissue paper, and the restoration was abandoned.

If you want to wipe out every bit of paint, body filler, and rust on your project, chemical stripping is a plausible method. Not to be confused with acid dipping-wherein steel parts are immersed in a concentrated bath of hydrochloric acid to make them lighter for racing-chemical stripping is a much milder process that is safe and yields great results when performed by properly trained personnel.

First, the part is immersed in a caustic soda bath for one to two days to remove all paint, undercoating, and sealer. This solution consists of a strong lye-based soap mixed with 20 percent water. After the first dip, the metal is immersed in fresh water and pressure-washed with the same water. At this point, all rust will be visible. The rust is removed by submerging the part in a 20/80 mixture of hydrochloric acid and water for two to three days. Once the rust has been eliminated, the part is dipped in the fresh-water tank and pressure-washed a second time. Then it's put in the caustic soda bath for a day to neutralize remaining acid residue trapped inside boxed sections. The part is dunked into the fresh water and pressure-washed once again before getting an iron phosphate bath for two to three hours. (The iron phosphate coating prevents surface rust.) The piece is then allowed to air-dry for a day.

What happens next is critical. After air-drying, the part is baked at 375 degrees for half an hour. If this step is omitted, there is no guarantee that the corrosive action of the caustic bath and the acid bath can be halted. Despite the numerous fresh-water rinses, trace chemical residues can linger inside hard-to-reach locations and begin eating the metal from the inside out. Baking prevents this entropy.

After baking, the part is scuffed with Scotch-Brite and electro-primed with rust-inhibiting red oxide, which is applied with a positive electric charge. The part is grounded, so the primer is attracted to the bare metal surfaces much more so than if it went on without electrostatic assistance, ensuring coverage in every nook. Finally, the freshly primed part is returned to the oven for 10 minutes at 300 degrees. That last bake dries it and evaporates any last solvents that could react with the paint.

The obvious downside to chemical dipping is that the part to be stripped must be bare. If you want to strip a door, the upholstery, glass, chrome, rubber, and plastic must be removed beforehand. The same goes for any other part, from a headlight bucket to a body shell. And because of the numerous steps, chemical stripping isn't cheap. But if you want to be sure every square inch is down to bare metal, and you don't want to worry about sweeping up sand for the rest of your days, chemical dipping can't be beat.