With any vehicle, routine maintenance is a key essential in keeping you car running in tip-top condition. When spark plug wires fail, a car will hesitate, stumble, and run erratic, especially going up a hill or under a load. Changing spark plugs and wires can be a fairly easy task and save you hundreds of dollars a year in fuel costs, avoid roadside breakdowns, and keep your car from needing even more expensive work caused by neglect of simple maintenance.

|

Spark Plug Wire Maintenance - Tricks Of The Trade

|

Spark Plug Wire Maintenance - Tricks Of The Trade

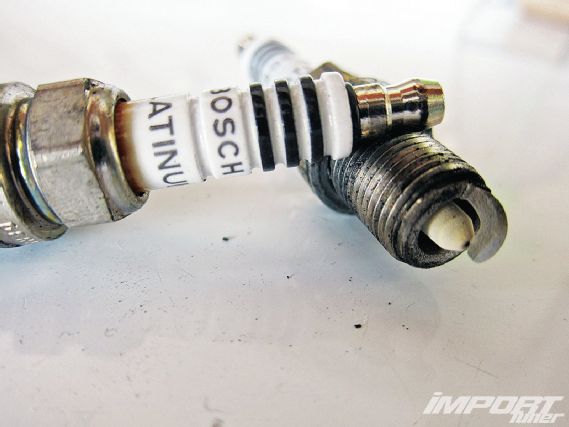

Today’s hotter running engines create extreme underhood temperatures, placing exceptional demands on spark plug wires. Over time, these wires can corrode or become damaged, requiring replacement. Though most auto manufacturers are claiming 80,000 miles between spark plug changes and only “as needed” on the wire replacements, few cars can make it that long without replacing these parts. To test the condition of your spark plug wires, we created this simple DIY diagnostics inspection to keep your car purring along.

|

Spark Plug Wire Maintenance - Tricks Of The Trade

|

Spark Plug Wire Maintenance - Tricks Of The Trade

Start with a visual inspection of the wires and the wire ends inside the protective boots. | Spark Plug Wire Maintenance - Tricks Of The Trade

For further checks, you’ll need a multimeter or volt-ohm meter. Testing a spark plug wire’s ohm resistance with a multimeter is a good way to verify they are in working condition, and if the wires are capable of delivering the required voltage to the spark plug. A multimeter will display how much resistance there is to the current that passes through the wire. Older plug wires will typically show more resistance, indicating they need replacement.

|

Spark Plug Wire Maintenance - Tricks Of The Trade

|

Spark Plug Wire Maintenance - Tricks Of The Trade

To test the wires, set your meter to Ohms. If it doesn’t say Ohms, look for the Greek symbol for Omega. Connect one lead to one end of the wire, and the other lead to the other end of the wire. What you’re checking for is called continuity. High resistance will indicate there is damage or corrosion somewhere in the wire. Refer to your vehicle’s owner’s manual for a list of acceptable reading ranges. Moving on to the next step, while keeping the meter hooked up to the wire, begin bending and flexing the wire while you monitor the voltage. If the voltage fluctuates, there is a break in the wire.