Brock Fraser has owned turbocharged cars for more than 20 years. The University of Tennessee engineering graduate and full-time car guy started his professional career at a performance chip tuning company before moving to engine development at one of the world’s largest tractor companies. His passion, however, has always been devising custom turbocharger installations. This self-professed Porsche guy currently drives a ’90 Carrera with his own twin-turbo installation making 530 horsepower at the wheels. When Fraser moved to BorgWarner 10 years ago, it seemed preordained that he would eventually shake up the world of aftermarket turbocharging.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

"We wanted to get this right on the first try."

Many innovations in the automotive world first arrive as an original equipment (O.E.) application. Large supplier companies prefer to have at least one customer already on the hook before investing in expensive research efforts and manufacturing tooling. But Fraser, who moved up the ladder to become BorgWarner’s Global Director of Application Engineering, had a different idea. What I pitched to senior management about a year and a half ago was to do this in reverse, says Fraser. Let’s take some of these technologies that we have been experimenting with for the past few years and let’s launch it first in the aftermarket. Fraser reasoned that he could supply a group of influential enthusiasts and tuners who were thirsty for innovative products, and at the same time, by building a whole series of turbocharger systems in different sizes, he would be able to respond quickly to O.E. development requests for high-technology turbochargers.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

Fraser put together a skunkworks team of drag racers, autocrossers, road racers and hot-rodders that he found within BorgWarner to work on the next generation of turbochargers. Half are true car guyspeople who really have this in their blood, and that helps, he says. Eventually, the new system became known as the company’s EFR Series. The acronym stands for Engineered For Racing.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

The Turbo

Turbocharging is the enthusiast’s best and most effective weapon when it comes to squeezing more performance out of internal combustion engines. Seeing the success with piston aircraft engines, carmakers began experimenting with using exhaust gases to power a turbine wheel that in turn was connected to a compressor to cram more air and fuel into the combustion chamber, without most of the power-sapping losses inherent with a belt- or gear-driven supercharger. Cars like the early ’70s Porsche 911 and BMW 2002 and the Saab Turbo of the late ’70s opened the door and today, turbocharged cars and light trucks, both gasoline and diesel, are commonplace.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

Home-Brew

At the same time carmakers were producing their early turbocharging efforts, backyard mechanics and professional tuners realized that there was horsepower to be gained simply by bolting on a turbo. Reeves Callaway, whose later projects have included racing turbocharged Corvettes at Le Mans, got his start in the ’70s by creating turbocharger kits for the BMW 320i and eventually kits for Volkswagens, Audis and a twin-turbo setup for the Alfa Romeo GTV6.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

For the home mechanic with a pipe bender, installing a turbocharger is reasonably straightforward, even if the resulting maze of exhaust pipes, intake hoses, wastegate(s), oil lines, coolant hoses and sensors belies the actual simplicity. Software and algorithms that used to be car companies’ most closely held secrets are now hacked and shared such that a kid with a laptop can control fuel injector duration and ignition timing on every stroke of the piston, keeping things under control and preventing catastrophe.

Modern cars have low hood lines to promote improved aerodynamics, and finding room underhood to put everything has become a real challenge. Still, compared to the traditional ways of making power through compression ratio, camshaft lift and timing, bigger valves, multiple carburetors and bundle-of-snakes exhaust systems, bolting on a turbo kit is a weekend project.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

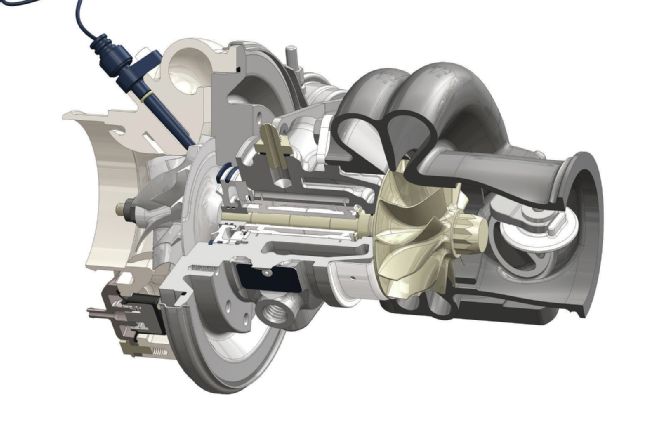

Build It As A System

BorgWarner’s new EFR Series consists of a range of turbochargers, with turbines from 55 to 80 millimeters in diameter and compressors from 62 to 91 mm in diameter. The range of sizes allows the turbocharger to be tailored to specific applications. The EFR turbine housings are made with investment castings in high-temperature and corrosion-resistant stainless steel, yielding a surface that rivals machined finishes. The housing includes an integrated high-volume wastegate and boost control solenoid valve, eliminating the need to package additional components during installation. Inside the stainless steel housing, the turbine on the exhaust side is an investment casting of Gamma Titanium aluminide, an exotic material that forms an inter-metallic composite that is halfway between a ceramic and a metal. Gamma-Ti is under study for gas-turbine aircraft engines and BorgWarner’s use of the material is one of the first industrial applications. The density of the inter-metallic is about half that of conventional high-nickel steel, making a turbine wheel that weighs half as much and is very similar in mass to the aluminum compressor wheel on the other end of the shaft. This lessens the inertia of the system and allows the turbo to spin up faster, producing boost quicker. The turbo spins at up to 168,000 rpm and lightweight ceramic balls are used in the bearings that support the main shaft, allowing the turbo to spin up even more quickly and reduces losses at low turbo speeds to improve fuel efficiency.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging

How Much And Where?

All of this technology comes at a price, but Fraser insists the EFR system provides good value. When you look at it from a system perspective, it’s actually a cheaper solution than buying a premium turbo, a blow-off valve, and an external wastegate, Fraser says. BorgWarner has no direct aftermarket sales channel, relying instead upon a system of distributors, some of which were directly involved in testing prototypes of the new EFR system components. Finding a distributor or tuner who can sell you a single EFR turbocharger or a system designed for your car is only as far away as a simple search of the Internet and validates Brock Fraser’s conviction that the introduction of new technologies that enthusiasts want can be accelerated by doing it in the aftermarket first.

|

Borgwarner Develops A New System Of Turbocharging

|

Borgwarner Develops A New System Of Turbocharging