| AEM Engine Position Module - Tech

| AEM Engine Position Module - Tech

You're a Quick 16 class drag racer and are about to take your game to the next level. You've built dozens of cars in the past; your current EG coupe dragger has been changes on a daily basis. Its built, turbocharged B18C had no problems churning out 450 whp at around 20psi and throwing down consistent 10.8s at every event last season-you know what it takes to go fast, and you're sure to do everything right the first time. Staying competitive this year, however, means you'll need more power. Your trusty T3/T4 has been swapped in favor of a GT42R that promises boost in excess of 40psi; your 750cc RCs have been chucked in favor of 1,600s. To light the whole mix, a time-honored, external coil-and-box ignition system increases spark output in lethal proportions. More air, more fuel and more spark equals more power, right? Not so fast.

| AEM Engine Position Module - Tech

| AEM Engine Position Module - Tech

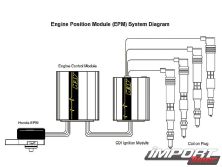

"The problem we ran into when our first Honda drag cars were going for big power," explained lead AEM engineer John Romero, "was that their OE distributors simply couldn't handle the voltage needed to fire the spark plugs." This problem is typical among big-power racers, fielding distributor-governed cars, like Honda and DSM platforms. Any external ignition system that works with the OE distributor can only increase spark output by increasing voltage to the primary side of its single, internal coil. Under extreme cylinder pressures, from high boost, rich AFRs or loads of nitrous, fully compressed cylinders can be so electrically un-conducive, that the spark energy's path of least resistance is a jump to the following cylinder's "tower" in the distributor cap, instead of across the intended spark plug gap in the combustion chamber-a phenomenon known as "spark scatter".

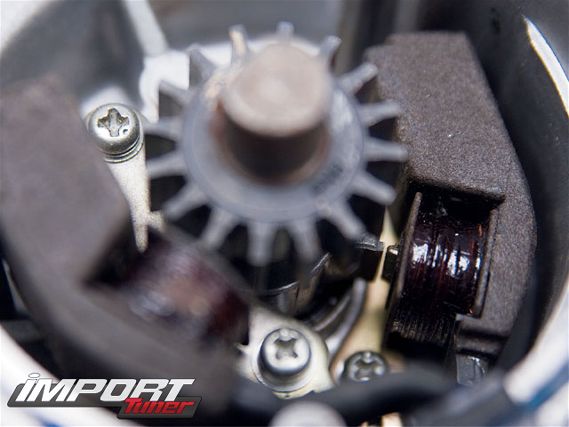

| Below the distributor's ignition components, we see the cam and crank position sensors.

| Below the distributor's ignition components, we see the cam and crank position sensors.

"In stock situations, there would never be enough spark energy to jump the 1-1/2-inch distance to another cylinder's spark tower in the distributor cap," explained John, "but when the distributor's coil is force-fed energy from an external ignition system, it becomes easy if conditions are too extreme, especially if the gap is shortened by electronically changing the ignition timing." Rpm can become a limiting factor, too. "As rpm increases, the amount of time the coil has to build a charge-it's dwell time-decreases," he continued, "at high energy levels and engine speeds, the OE coil can't distribute maximum spark energy to its plugs."

Switching to an individual coil system would eliminate these headaches, but converting from a distributor isn't an easy trick. The OEM Honda distributor also houses cam and crank position sensors, and the factory ECU only allows for communication with one coil. Any individual coil setup would have to be commanded by a stand-alone ECU with four separate coil drivers, and removing the distributor completely would render it blind relative to engine position. The common solution at the time was to modify the distributor-so its cam and crank position sensors could be retained-and remove its ignition components, then hotwire-in connections for individual coil packs from Honda CBR motorcycle engines. "We saw a lot of hack jobs out there," laughed John, "So we thought, 'There has to be a better way'.

| Below it, on the opposite side is the single-tooth cam position sensor

| Below it, on the opposite side is the single-tooth cam position sensor

AEM's EPM was designed not only to fill this void, but also to offer some added improvements over the OE Honda design, starting with the function of the cam and crank position sensors. The OE distributor's sensors are magnetic; not only do they add a bit of resistance to rotational movement and are bulky, but their magnetic design is also susceptible to electro-magnetic interference that requires they reach a certain rotational speed before their signal is strong enough to be read by the ECU. The EPM uses twin optical pickups and a laser-etched trigger wheel in place of Honda's old-school magnets to provide a free-spinning, zero-speed alternative, that offers immediate signal generation from the moment the engine is cranked-and cannot be corrupted by outside "noise". Every EPM trigger wheel features a 24 pulse-per-cycle output for the crank sensor-the industry standard for most modern fuel injected vehicles, but a more precise design than found in some older Honda and Mitsubishi distributors-and simpler than those used in others, like Nissan's RB engines.

| One of the EPM test mules - John Ramero's 200-plus mph 1.5L Civic

| One of the EPM test mules - John Ramero's 200-plus mph 1.5L Civic

Converting To Epm: What You'll NeedBefore the EPM was even considered for mass production, it was race-proven in some of the most demanding situations. "Bisi (Ezerioha) is using one on his all-motor F22 now," John pointed out, "we've had beta units in all our drag cars, Steph's S2000 drifter..." John even had one on his 1.5L Civic when it set its current class land speed record at 205mph. "You can actually see my personal D.I.Y solution that led to the development of the EPM in older photos of the car," he told us, "We actually intended to produce only a limited supply of EPMs for our friends in the racing community who were looking for a product like it. But it's become so popular that we've made it available to anyone, and for less than they'd probably spend on a D.I.Y setup."

The EMP will not work with the OEM ECU, but if you in need to switch over to a coil-on-plug ignition, you're no-doubt running a stand-alone system anyway. One of the EPM's strengths is that it will work with any engine management system that recognizes the common 24-1 input for crank and cam signal. "We designed it to work specifically with the AEM EMS," John pointed out, "but we've seen guys using it with Haltech and MoTeC EMSs, Autronic, LINK...We didn't want it to be a limiting component." The EPM also accommodates a wide variety of coil pack options, but AEM offers application-specific units capable of huge power production, and features plug 'n' play installation.