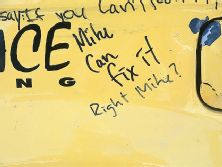

"Fortunately, I used to be a blacksmith. Does anybody have a big hammer?" I had just driven over a big rock and bent the inner edge of my wheel concave, resulting in immediate loss of all air pressure. Uttered with a thick Swiss accent, these words were my first inkling that everything was going to be all right. By the time my friend was done, the wheel was not noticeably less round than the other two slightly bent wheels on my old beater, and I was saved something like 700 miles of driving on a space-saver spare before I could get home and repair or replace the wheel. As it turns out, the wheel is still on the car 7 months later, a total repair cost of $0 being the operating principle. Just this weekend, I saw the work of a truly Big F. Hammer. Dave and Josh, from that magazine down the hall, in their second rally hit a rock sideways and bent a rear control arm to where they had about 20-degrees positive camber. They kept going, and managed to pass a Mazda with no tire on one of its wheels. At the service, Mike Welch of Road/Race Engineering came over with his hammer: a Ford axle with a 40-lb lead brick on the end. Josh and Dave each tried swinging it, but it swung them instead. A burly spectator stepped forward and, a few minutes later, the wheel was pointed as close to straight as it needed to be. Josh and Dave were the only team in their class to finish the 3-day event.

Sometimes things get bent. Obviously, the right way to fix them is to replace the damaged parts, but if you're constrained by a lack of parts, tools or time, bending them back may let you finish the day and get to a place where repairs can be carried out properly--without the costs of emergency service. Even in engineering school where mathematical analysis rules, everyone knows that the BFH, or its less refined cousin, Mr. B. F. Rock, is a legitimate means of applying force. There are even entire sequences of courses on mathematical analysis of hitting things with a calibrated BFH.

Finesse is important any time power is involved, the ideal, as in driving, being plenty of horsepower and even more finesse. Finesse is up to your judgement, but power--like a stick-and-ball sport--comes from follow through. Swing for where it is and you'll bounce off. Instead, swing for where you want it to be. Quality counts even with a big chunk of steel you use to beat on things. Inexpensive steel from countries that specialize in low-cost goods is liable to fracture dangerously. While safety glasses must be worn any time steel strikes steel, quality steels from a reputable company (dare I say Made in the USA?) are less likely to crack or chip. Tool companies talk about alloys and manufacturing processes that result in "safe fractures," in which tools break cleanly without sending tiny slivers of steel flying.

As with any tool, choosing the right hammer for the job is important. For example, a lead brick was soft enough to allow a big guy to beat on Dave's junkyard alloy wheel without restyling its surface, and the wheel bearings haven't given up yet. The downside is its made of lead. Always avoid handling lead with your bare hands. Also, be well aware of the risk of breathing lead dust because the stuff--though apparently harmless initially--has long-term effects, making it one of the nastier poisons out there. Even though you can buy an officially manufactured hammer with a lead head, it's not something you want coming into contact with the rest of your hand tools in your toolbox--it would have to be treated as a hazardous material. Soft metal hammers of brass or copper are much to be preferred. There are more kinds and sizes of hammers and mallets available than can be outlined here, but if your need a BFH, you can probably find one that's just right.